методика количественной оценки технологичности конструкции

реклама

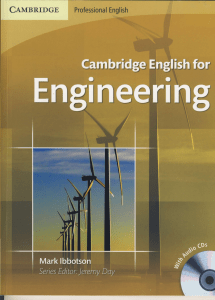

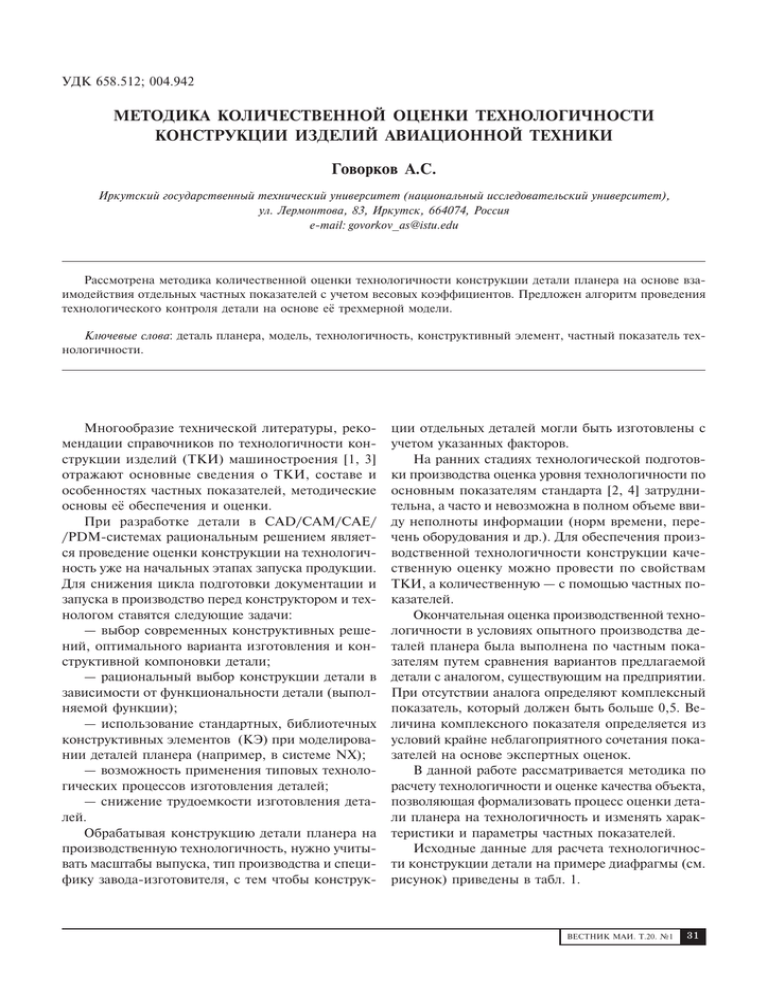

Àâèàöèîííàÿ òåõíèêà Aircraft Engineering ÓÄÊ 658.512; 004.942 ÌÅÒÎÄÈÊÀ ÊÎËÈ×ÅÑÒÂÅÍÍÎÉ ÎÖÅÍÊÈ ÒÅÕÍÎËÎÃÈ×ÍÎÑÒÈ ÊÎÍÑÒÐÓÊÖÈÈ ÈÇÄÅËÈÉ ÀÂÈÀÖÈÎÍÍÎÉ ÒÅÕÍÈÊÈ Ãîâîðêîâ À.Ñ. Èðêóòñêèé ãîñóäàðñòâåííûé òåõíè÷åñêèé óíèâåðñèòåò (íàöèîíàëüíûé èññëåäîâàòåëüñêèé óíèâåðñèòåò), óë. Ëåðìîíòîâà, 83, Èðêóòñê, 664074, Ðîññèÿ e-mail: govorkov_as@istu.edu Ðàññìîòðåíà ìåòîäèêà êîëè÷åñòâåííîé îöåíêè òåõíîëîãè÷íîñòè êîíñòðóêöèè äåòàëè ïëàíåðà íà îñíîâå âçàèìîäåéñòâèÿ îòäåëüíûõ ÷àñòíûõ ïîêàçàòåëåé ñ ó÷åòîì âåñîâûõ êîýôôèöèåíòîâ. Ïðåäëîæåí àëãîðèòì ïðîâåäåíèÿ òåõíîëîãè÷åñêîãî êîíòðîëÿ äåòàëè íà îñíîâå å¸ òðåõìåðíîé ìîäåëè. Êëþ÷åâûå ñëîâà: äåòàëü ïëàíåðà, ìîäåëü, òåõíîëîãè÷íîñòü, êîíñòðóêòèâíûé ýëåìåíò, ÷àñòíûé ïîêàçàòåëü òåõíîëîãè÷íîñòè. Ìíîãîîáðàçèå òåõíè÷åñêîé ëèòåðàòóðû, ðåêîìåíäàöèè ñïðàâî÷íèêîâ ïî òåõíîëîãè÷íîñòè êîíñòðóêöèè èçäåëèé (ÒÊÈ) ìàøèíîñòðîåíèÿ [1, 3] îòðàæàþò îñíîâíûå ñâåäåíèÿ î ÒÊÈ, ñîñòàâå è îñîáåííîñòÿõ ÷àñòíûõ ïîêàçàòåëåé, ìåòîäè÷åñêèå îñíîâû å¸ îáåñïå÷åíèÿ è îöåíêè. Ïðè ðàçðàáîòêå äåòàëè â CAD/CAM/CAE/ /PDM-ñèñòåìàõ ðàöèîíàëüíûì ðåøåíèåì ÿâëÿåòñÿ ïðîâåäåíèå îöåíêè êîíñòðóêöèè íà òåõíîëîãè÷íîñòü óæå íà íà÷àëüíûõ ýòàïàõ çàïóñêà ïðîäóêöèè. Äëÿ ñíèæåíèÿ öèêëà ïîäãîòîâêè äîêóìåíòàöèè è çàïóñêà â ïðîèçâîäñòâî ïåðåä êîíñòðóêòîðîì è òåõíîëîãîì ñòàâÿòñÿ ñëåäóþùèå çàäà÷è: âûáîð ñîâðåìåííûõ êîíñòðóêòèâíûõ ðåøåíèé, îïòèìàëüíîãî âàðèàíòà èçãîòîâëåíèÿ è êîíñòðóêòèâíîé êîìïîíîâêè äåòàëè; ðàöèîíàëüíûé âûáîð êîíñòðóêöèè äåòàëè â çàâèñèìîñòè îò ôóíêöèîíàëüíîñòè äåòàëè (âûïîëíÿåìîé ôóíêöèè); èñïîëüçîâàíèå ñòàíäàðòíûõ, áèáëèîòå÷íûõ êîíñòðóêòèâíûõ ýëåìåíòîâ (ÊÝ) ïðè ìîäåëèðîâàíèè äåòàëåé ïëàíåðà (íàïðèìåð, â ñèñòåìå NX); âîçìîæíîñòü ïðèìåíåíèÿ òèïîâûõ òåõíîëîãè÷åñêèõ ïðîöåññîâ èçãîòîâëåíèÿ äåòàëåé; ñíèæåíèå òðóäîåìêîñòè èçãîòîâëåíèÿ äåòàëåé. Îáðàáàòûâàÿ êîíñòðóêöèþ äåòàëè ïëàíåðà íà ïðîèçâîäñòâåííóþ òåõíîëîãè÷íîñòü, íóæíî ó÷èòûâàòü ìàñøòàáû âûïóñêà, òèï ïðîèçâîäñòâà è ñïåöèôèêó çàâîäà-èçãîòîâèòåëÿ, ñ òåì ÷òîáû êîíñòðóê- öèè îòäåëüíûõ äåòàëåé ìîãëè áûòü èçãîòîâëåíû ñ ó÷åòîì óêàçàííûõ ôàêòîðîâ. Íà ðàííèõ ñòàäèÿõ òåõíîëîãè÷åñêîé ïîäãîòîâêè ïðîèçâîäñòâà îöåíêà óðîâíÿ òåõíîëîãè÷íîñòè ïî îñíîâíûì ïîêàçàòåëÿì ñòàíäàðòà [2, 4] çàòðóäíèòåëüíà, à ÷àñòî è íåâîçìîæíà â ïîëíîì îáúåìå ââèäó íåïîëíîòû èíôîðìàöèè (íîðì âðåìåíè, ïåðå÷åíü îáîðóäîâàíèÿ è äð.). Äëÿ îáåñïå÷åíèÿ ïðîèçâîäñòâåííîé òåõíîëîãè÷íîñòè êîíñòðóêöèè êà÷åñòâåííóþ îöåíêó ìîæíî ïðîâåñòè ïî ñâîéñòâàì ÒÊÈ, à êîëè÷åñòâåííóþ ñ ïîìîùüþ ÷àñòíûõ ïîêàçàòåëåé. Îêîí÷àòåëüíàÿ îöåíêà ïðîèçâîäñòâåííîé òåõíîëîãè÷íîñòè â óñëîâèÿõ îïûòíîãî ïðîèçâîäñòâà äåòàëåé ïëàíåðà áûëà âûïîëíåíà ïî ÷àñòíûì ïîêàçàòåëÿì ïóòåì ñðàâíåíèÿ âàðèàíòîâ ïðåäëàãàåìîé äåòàëè ñ àíàëîãîì, ñóùåñòâóþùèì íà ïðåäïðèÿòèè. Ïðè îòñóòñòâèè àíàëîãà îïðåäåëÿþò êîìïëåêñíûé ïîêàçàòåëü, êîòîðûé äîëæåí áûòü áîëüøå 0,5. Âåëè÷èíà êîìïëåêñíîãî ïîêàçàòåëÿ îïðåäåëÿåòñÿ èç óñëîâèé êðàéíå íåáëàãîïðèÿòíîãî ñî÷åòàíèÿ ïîêàçàòåëåé íà îñíîâå ýêñïåðòíûõ îöåíîê.  äàííîé ðàáîòå ðàññìàòðèâàåòñÿ ìåòîäèêà ïî ðàñ÷åòó òåõíîëîãè÷íîñòè è îöåíêå êà÷åñòâà îáúåêòà, ïîçâîëÿþùàÿ ôîðìàëèçîâàòü ïðîöåññ îöåíêè äåòàëè ïëàíåðà íà òåõíîëîãè÷íîñòü è èçìåíÿòü õàðàêòåðèñòèêè è ïàðàìåòðû ÷àñòíûõ ïîêàçàòåëåé. Èñõîäíûå äàííûå äëÿ ðàñ÷åòà òåõíîëîãè÷íîñòè êîíñòðóêöèè äåòàëè íà ïðèìåðå äèàôðàãìû (ñì. ðèñóíîê) ïðèâåäåíû â òàáë. 1. ÂÅÑÒÍÈÊ ÌÀÈ. Ò.20. ¹1 ! Àâèàöèîííàÿ òåõíèêà Aircraft Engineering íèÿ âàðèàíòîâ òåõíîëîãèè îñóùåñòâëåíà ñ ïîìîùüþ êîìïëåêñíîãî ïîêàçàòåëÿ (òàáë. 2), [2] n p= ∑ ki ϕi i =1 n ∑ ϕi , (1) i =1 ãäå ki çíà÷åíèå i-ãî ÷àñòíîãî ïîêàçàòåëÿ òåõíîëîãè÷íîñòè äåòàëè; Äèàôðàãìà òîðìîçíîãî ùèòêà ñàìîë¸òà Êîëè÷åñòâåííàÿ îöåíêà òåõíîëîãè÷íîñòè äåòàëè «äèàôðàãìà» íà ýòàïå ïðîåêòèðîâàíèÿ è ñðàâíå- ϕi êîýôôèöèåíò âåñîìîñòè i-ãî ÷àñòíîãî ïîêàçàòåëÿ òåõíîëîãè÷íîñòè äåòàëè; n êîëè÷åñòâî ïðèíÿòûõ ïîêàçàòåëåé, îïðåäåëÿåìûõ ýêñïåðòîì, äîëæíî áûòü íå ìåíåå 5. Òàáëèöà 1 Èñõîäíûå äàííûå äëÿ ðàñ÷åòà òåõíîëîãè÷íîñòè êîíñòðóêöèè äèàôðàãìû òîðìîçíîãî ùèòêà ñàìîëåòà ¹ Íàèìåíîâàíèå äàííûõ 1 Äàííûå ïî ãåîìåòðè÷åñêèì ïàðàìåòðàì 2 Îáúåì âûïóñêà â ãîä 3 Ìàññà äåòàëè 4 Êîëè÷åñòâî íàèìåíîâàíèé êîíñòðóêòèâíûõ ýëåìåíòîâ 5 Âûõîä íà òåîðåòè÷åñêèé êîíòóð 6 Ìàòåðèàë 7 Äîïóñê íà àýðîäèíàìè÷åñêèé êîíòóð Çíà÷åíèå Ìîäåëü äåòàëè, òåõíè÷åñêèå óñëîâèÿ 0-100 øò. Íå áîëåå 0,100 êã Áîëåå 3 Äà Ä16ÀÒ ±1,0 Òàáëèöà 2 Ñâîäíàÿ âåäîìîñòü ðàñ÷åòà ïîêàçàòåëåé òåõíîëîãè÷íîñòè äåòàëè ÀÒ ¹ Íàèìåíîâàíèå ÷àñòíîãî ïîêàçàòåëÿ òåõíîëîãè÷íîñòè Êîýôôèöèåíò âåñîìîñòè, ϕi ki ϕi 1 Îáúåì âûïóñêà â ãîä, kãîä 0,30 0,06 0,018 2 Òåõíîëîãè÷íîñòü ðàçäåëèòåëüíîé îïåðàöèè, kðàç 1,00 0,12 0,12 3 Òåõíîëîãè÷íîñòü ôîðìîèçìåíÿþùåé îïåðàöèè, kôîð 0,90 0,13 0,117 4 Óðîâåíü ïîâòîðÿåìîñòè ÊÝ, âõîäÿùèõ â èçäåëèå, kýë 0,90 0,12 0,108 5 Ìàññà äåòàëè, kì 1,00 0,07 0,07 6 Ãàáàðèòíûå ðàçìåðû, kðàç 0,80 0,08 0,064 7 Ôîðìà îáâîäîâ, kô.îá 0,75 0,06 0,045 8 Ôîðìà êîíòóðà, kô.êîí 0,60 0,05 0,03 9 Óðîâåíü êðèâèçíû, kóð.êð 0,9 0,11 0,099 10 Äîïóñê íà àýðîäèíàìè÷åñêèé êîíòóð, kàýð 0,40 0,05 0,02 11 Âûõîä íà îáâîä, kÒÊ 0,5 0,08 0,04 12 Ðàñïîëîæåíèå ýëåìåíòîâ îòíîñèòåëüíî óñëîâíîé ïëîñêîñòè äåòàëè, kN 0,8 0,07 0,056 1,00 0,787 Èòîãî ! Çíà÷åíèå ïîêàçàòåëÿ ÂÅÑÒÍÈÊ ÌÀÈ. Ò.20. ¹1 Àâèàöèîííàÿ òåõíèêà Aircraft Engineering Äàëåå âåëè÷èíû ïîêàçàòåëåé óðîâíÿ òåõíîëîãè÷íîñòè ïîêàçàòåëåé â äàííîé ðàáîòå ïðèíÿòû óñëîâíûìè. Ïîêàçàòåëè îáúåìà âûïóñêà â ãîä kãîä (òàáë. 3) îöåíèâàþò âîçìîæíîñòü ìåõàíèçàöèè è àâòîìàòèçàöèè ïðîöåññà èçãîòîâëåíèÿ äåòàëè. ×åì áîëüøå îáúåì âûïóñêà, òåì ýôôåêòèâíåå ïðèìåíåíèå ñðåäñòâ ìåõàíèçàöèè è àâòîìàòèçàöèè è, ñîîòâåòñòâåííî, ñóùåñòâåííåå ñíèæåíèå òðóäîåìêîñòè è ñåáåñòîèìîñòè äåòàëè. Ïîêàçàòåëü òåõíîëîãè÷íîñòè â çàâèñèìîñòè îò âèäà ðàçäåëèòåëüíîé kðàç îïåðàöèè ïðè èçãîòîâëåíèè çàãîòîâêè äåòàëè èç ëèñòà (òàáë. 4) ó÷èòûâàåò òàêîé ïîêàçàòåëü ÒÊÈ, êàê òåõíîëîãè÷åñêàÿ ñåáåñòîèìîñòü çàãîòîâêè. Ïîêàçàòåëü òåõíîëîãè÷íîñòè â çàâèñèìîñòè îò âèäà ôîðìîîáðàçóþùåé kôîð îïåðàöèè ïðè èçãîòîâëåíèè ôîðìû äåòàëè èç ëèñòà (òàáë. 5) ó÷èòûâàåò òàêîé ïîêàçàòåëü ÒÊÈ, êàê òåõíîëîãè÷åñêàÿ ñåáåñòîèìîñòü çàãîòîâêè, òåõíîëîãè÷åñêàÿ ïðîñòîòà. Òàáëèöà 3 Îáúåì âûïóñêà äåòàëåé ïëàíåðà â ãîä ¹ Îáúåì âûïóñêà äåòàëåé ïëàíåðà â ãîä kãîä 1 1-10 0,1 2 10-50 0,2 3 50-100 0,3 4 100-200 0,4 5 200-300 0,5 6 300-400 0,6 7 400-600 0,7 8 600-800 0,8 9 800-1000 0,9 10 1000 è âûøå 1,0 Òàáëèöà 4 Ïîêàçàòåëü òåõíîëîãè÷íîñòè â çàâèñèìîñòè îò âèäà ðàçäåëèòåëüíîé îïåðàöèè ¹ Òåõíîëîãè÷íîñòü ðàçäåëèòåëüíîé îïåðàöèè kðàç 1 Íà ôðåçåðíîì ñòàíêå ñ ×ÏÓ 1,0 2 Íà ôðåçåðíîì ñòàíêå ïî øàáëîíó 0,8 3  øòàìïå 0,6 4 Ãèëüîòèííûå íîæíèöû 0,4 5 Ðîëèêîâûå íîæíèöû 0,2 Òàáëèöà 5 Ïîêàçàòåëü òåõíîëîãè÷íîñòè â çàâèñèìîñòè îò âèäà ôîðìîîáðàçóþùåé îïåðàöèè ¹ Òåõíîëîãè÷íîñòü ôîðìîîáðàçóþùåé îïåðàöèè kôîð 1 Ôîðìîâêà ýëàñòè÷íîé ñðåäîé 1,0 2 Ôîðìîâêà íà ïàäàþùèõ ìîëîòàõ 0,8 3 Ãèáêà â øòàìïå 0,6 4 Îáòÿæêà 0,3 Ïðè íåñêîëüêèõ âèäàõ îïåðàöèé ôîðìîîáðàçîâàíèÿ îäíîé äåòàëè îïðåäåëÿþò ñðåäíåâçâåøåííîå çíà÷åíèå ïîêàçàòåëÿ ïî ôîðìóëå n kôîð ñð = ∑ kôîð i pi i =1 p , (2) ãäå ð îáùåå êîëè÷åñòâî ïðèìåíÿåìûõ ôîðìîîáðàçóþùèõ îïåðàöèé ïðè èçãîòîâëåíèè äåòàëè; kôîð i çíà÷åíèå ïàðàìåòðà òåõíîëîãè÷íîñòè ïî i-ìó ïàðàìåòðó; pi êîëè÷åñòâî îïåðàöèé i-ãî âèäà. Ïîêàçàòåëü kýë, õàðàêòåðèçóþùèé ïîâòîðÿåìîñòü êîíñòðóêòèâíûõ ýëåìåíòîâ, âõîäÿùèõ â êîíñòðóêöèþ äåòàëè, âûáèðàåòñÿ èç òàáë. 6. Ïðè êîëè÷åñòâå êîíñòðóêòèâíûõ ýëåìåíòîâ áîëåå 40 îöåíêà ïîêàçàòåëÿ ïðèíèìàåòñÿ â çàâèñèìîñòè îò ñëîæíîñòè ôîðìîîáðàçóþùåé îïåðàöèè â ïðåäåëàõ 0,400,10. Ïîêàçàòåëü kì, çàâèñÿùèé îò ìàññû äåòàëè, îïðåäåëÿåòñÿ ïî òàáë. 7 è ó÷èòûâàåò ñâîéñòâî ÒÊÈ. Äàííûå â òàáëèöå ïðèìåíèìû òîëüêî äëÿ äåòàëåé ïëàíåðà ñàìîëåòà. Ïîêàçàòåëü kðàç, õàðàêòåðèçóþùèé ãàáàðèòíûå ðàçìåðû äåòàëè, âûáèðàåòñÿ ïî òàáë. 8. Ïîêàçàòåëü kô.îá, ó÷èòûâàþùèé ôîðìó îáâîäîâ, îïðåäåëÿåòñÿ èç öåëåâîãî íàçíà÷åíèÿ âñåé äåòàëè èëè îòäåëüíûõ åå ýëåìåíòîâ. Ïîêàçàòåëè ôîðìû îáâîäîâ ïðèâåäåíû â òàáë. 9. Ïîêàçàòåëü kô.êîí, ó÷èòûâàþùèé ôîðìó êîíòóðà, îïðåäåëÿåòñÿ èç êîíñòðóêòèâíîãî ïðåäñòàâëåíèÿ äåòàëè èëè åå îòäåëüíûõ ýëåìåíòîâ: áîðò, ðåáðî è äð. Ïîêàçàòåëè ôîðìû êîíòóðîâ ïðèâåäåíû â òàáë. 10. Ïîêàçàòåëü kóð.êð, ó÷èòûâàþùèé óðîâåíü êðèâèçíû äåòàëè, îïðåäåëÿåòñÿ èç êîíñòðóêòèâíîãî ïðåäñòàâëåíèÿ äåòàëè èëè îòäåëüíûõ ýëåìåíòîâ. Ïîêàçàòåëè óðîâíÿ êðèâèçíû ïðèâåäåíû â òàáë. 11. ÂÅÑÒÍÈÊ ÌÀÈ. Ò.20. ¹1 !! Àâèàöèîííàÿ òåõíèêà Aircraft Engineering Òàáëèöà 6 Óðîâåíü ïîâòîðÿåìîñòè êîíñòðóêòèâíûõ ýëåìåíòîâ â äåòàëè ¹ Êîëè÷åñòâî íàèìåíîâàíèé ýëåìåíòîâ Êîëè÷åñòâî ýëåìåíòîâ kýë 1-2 1-4 1,0 Áîëåå 4 0,95 4-10 0,90 Áîëåå 10 0,85 10-20 0,80 Áîëåå 20 0,75 20-30 0,70 Áîëåå 30 0,60 30-40 0,50 Áîëåå 40 0,40 1 2 3 3-5 4 5 5-8 6 7 8-12 8 9 12-20 10 Òàáëèöà 9 Òàáëèöà 7 Ïîêàçàòåëü ôîðìû îáâîäîâ Ïîêàçàòåëü ìàññû äåòàëè ¹ Ìàññà äåòàëè, êã kì ¹ 1 0-0,5 1,0 1 Ïëîñêàÿ 1,0 2 0,5-1,0 0,8 2 Öèëèíäðè÷åñêàÿ 0,75 3 1,0-2,0 0,6 3 Êîíè÷åñêàÿ 0,5 4 2,0-5,0 0,4 4 Äâîéíîé êðèâèçíû 0,2 5 5,0-10,0 0,2 6 Áîëåå 10,0 0,1 Ïîêàçàòåëü ôîðìû êîíòóðîâ Ïîêàçàòåëü òåõíîëîãè÷íîñòè ãàáàðèòíûõ ðàçìåðîâ äåòàëè ¹ 1 Îäíîìåðíàÿ, l/b>5 Äëèíà l: äî 0,5 ¹ Ôîðìà êîíòóðîâ kô.êîí 1 Ïðÿìîëèíåéíàÿ 1,0 2 Äóãè îêðóæíîñòè 0,7 kðàç 3 Êðèâîëèíåéíàÿ 0,6 1 4 Ïðîèçâîëüíàÿ 0,5 2 Äëèíà l:äî 2 0,85 3 Äëèíà l:äî 6 0,75 4 Äëèíà l:ñâûøå 6 0,5 ¹ äî 0,5 0,9 1 Ìàëàÿ êðèâèçíà, r>1 0,9 6 äî 2 0,8 2 Áîëüøàÿ êðèâèçíà, r<1 0,6 7 äî 6 0,7 8 ñâûøå 6 0,4 äî 0,5 0,8 10 äî 2 0,7 11 äî 6 0,5 12 ñâûøå 6 0,3 5 9 !" Òèï äåòàëè kô.îá Òàáëèöà 10 Òàáëèöà 8 Ãàáàðèòíûå ðàçìåðû, ì Ôîðìà îáâîäîâ Äâóìåðíàÿ, l/b<5 Òðåõìåðíàÿ ÂÅÑÒÍÈÊ ÌÀÈ. Ò.20. ¹1 Òàáëèöà 11 Ïîêàçàòåëü óðîâíÿ êðèâèçíû Óðîâåíü êðèâèçíû kóð.êð Ïîêàçàòåëü kàýð, ó÷èòûâàþùèé äîïóñê íà àýðîäèíàìè÷åñêèé êîíòóð, îïðåäåëÿåòñÿ èç öåëåâîé ôóíêöèè äåòàëè (òàáë. 12). Ïîêàçàòåëü kÒÊ, ó÷èòûâàþùèé âûõîä ýëåìåíòîâ äåòàëè íà òåîðåòè÷åñêèé êîíòóð, îïðåäåëÿåòñÿ â çàâèñèìîñòè îò öåëåâîé ôóíêöèè äåòàëè (òàáë. 13). Ïîêàçàòåëü kN, ó÷èòûâàþùèé ðàñïîëîæåíèå êîíñòðóêòèâíûõ ýëåìåíòîâ äåòàëè îòíîñèòåëüíî óëîâíîé ïëîñêîñòè äåòàëè, îïðåäåëÿåòñÿ ïî òàáë. 14. Àâèàöèîííàÿ òåõíèêà Aircraft Engineering Òàáëèöà 12 Ïîêàçàòåëü äîïóñêà íà àýðîäèíàìè÷åñêèé êîíòóð ¹ Äîïóñê íà àýðîäèíàìè÷åñêèé êîíòóð kàýð 1 0,5-0,8 0,2 2 0,8-1,0 0,4 3 1,0-1,5 0,6 4 1,5-2,0 0,8 5 2,0-3,0 1 Òàáëèöà 13 Ïîêàçàòåëü âûõîäà íà òåîðåòè÷åñêèé îáâîä ¹ Âûõîä íà îáâîä kÒÊ 1 Âûõîäèò 0,5 2 Íå âûõîäèò 1,0 Òàáëèöà 14 Ïîêàçàòåëü ðàñïîëîæåíèÿ ýëåìåíòîâ ¹ Ðàñïîëîæåíèå ýëåìåíòîâ kN 1 Îäíîñòîðîííåå 1,0 2 Äâóñòîðîíåå 0,8 Èñïîëüçóÿ ïðèâåäåííóþ âûøå ìåòîäèêó, íàõîäèì ïîêàçàòåëè ki ïðèìåíèòåëüíî ê êîíñòðóêöèè äèàôðàãìû (çàïîëíÿåì òàáë. 1) è ñ ó÷åòîì êîýôôèöèåíòîâ âåñîìîñòè îïðåäåëÿåì ki ϕi . Êîýôôèöèåíòû âåñîìîñòè ïîêàçàòåëåé òåõíîëîãè÷íîñòè îïðåäåëåíû ýêñïåðòíûì ïóòåì. Äëÿ îöåíêè äðóãèõ äåòàëåé ïëàíåðà ìîãóò áûòü èñïîëüçîâàíû èëè âñå, èëè ÷àñòü ïîêàçàòåëåé, à èõ êîýôôèöèåíòû âåñîìîñòè äîëæíû áûòü âûÿâëåíû íà îñíîâå íîâûõ ýêñïåðòíûõ îöåíîê. Ñóììà âûáðàííûõ êîýôôèöèåíòîâ âåñîìîñòè ðàâíÿåòñÿ åäèíèöå. Òàêèì îáðàçîì, îïðåäåëÿåì êîìïëåêñíûé ïîêàçàòåëü òåõíîëîãè÷íîñòè äèàôðàãìû ïî ôîðìóëå (1) 0,787 = 0,787. p= 1  ðåçóëüòàòå ïðîâåäåííûõ ðàñ÷åòîâ ïîëó÷èëè ñëåäóþùèå çíà÷åíèÿ òåõíîëîãè÷íîñòè äèàôðàãìû: 1) äëÿ íîâîé äåòàëè 0,5; 2) ðàññ÷èòàííîå ïî ìåòîäèêå 0,787. Ñðàâíèâàÿ êîìïëåêñíûé ïîêàçàòåëü, ðàññ÷èòàííûé ïî ïðèâåäåííîé ìåòîäèêå, ñ áàçîâûì äëÿ íîâîé äåòàëè, ìîæíî ñäåëàòü âûâîä, ÷òî ïðîåêòèðóåìàÿ êîíñòðóêöèÿ äèàôðàãìû òåõíîëîãè÷íà è ìîæåò áûòü ïðèíÿòà äëÿ èñïîëüçîâàíèÿ â ïðîèçâîä- ñòâåííûõ óñëîâèÿõ. Ïðåäëàãàåìàÿ ìåòîäèêà ïðîâåðåíà ïðè êîíñòðóèðîâàíèè øòàìïóåìûõ äåòàëåé èç ëèñòà è îòðàæàåò ðåàëüíîñòü ïðîöåññà êîíñòðóèðîâàíèÿ è èçãîòîâëåíèÿ. Ñëåäîâàòåëüíî, ïðåäëàãàåìàÿ ìåòîäèêà îòðàáîòêè êîíñòðóêöèè äåòàëè íà òåõíîëîãè÷íîñòü ìîæåò óñïåøíî ïðèìåíÿòüñÿ íà ïðàêòèêå äëÿ ðàñ÷åòà ïðîèçâîäñòâåííîé òåõíîëîãè÷íîñòè è îöåíêè êà÷åñòâà íîâûõ ðàçðàáàòûâàåìûõ äåòàëåé ïëàíåðà, äëÿ êîòîðûõ íà ðàííèõ ñòàäèÿõ òåõíîëîãè÷åñêîé ïîäãîòîâêè ïðîèçâîäñòâà îöåíêà óðîâíÿ òåõíîëîãè÷íîñòè ïî îñíîâíûì ïîêàçàòåëÿì ñòàíäàðòà çàòðóäíèòåëüíà è íåâîçìîæíà ââèäó íåïîëíîòû èíôîðìàöèè, à ïî äîïîëíèòåëüíûì ïîêàçàòåëÿì îãðàíè÷åíà, òàê êàê îòðàæàåò òîëüêî êîíñòðóêòèâíûå ýëåìåíòû. Ïðèìåíåíèå äàííîé ìåòîäèêè â ñèñòåìå àíàëèçà ÒÊÈ íà ðàííèõ ýòàïàõ ïðîåêòèðîâàíèÿ äåòàëåé ïëàíåðà ïîçâîëÿåò ïðåîáðàçîâûâàòü ìîäåëè äåòàëåé â óñëîâèÿõ èçìåíÿþùåãîñÿ ñëîâàðÿ òåõíîëîãè÷åñêîãî ïðåäñòàâëåíèÿ ïðè çíà÷èòåëüíîì ïîñòîÿíñòâå ñëîâàðÿ êîíñòðóêòîðñêîãî ïðåäñòàâëåíèÿ. Âðåìåííîå èçìåíåíèå îáóñëîâëåíî ðàçâèòèåì òåõíîëîãèé è ìåòîäîâ òåõíîëîãè÷åñêîãî ïðîåêòèðîâàíèÿ. Ïðåäëàãàåìàÿ ñèñòåìà àíàëèçà ÒÊÈ äîëæíà, ïî âîçìîæíîñòè, èçîëèðîâàòü êîíñòðóêòîðà îò ïðîñòðàíñòâåííî-âðåìåííûõ èçìåíåíèé òåõíîëîãè÷åñêîãî áàçèñà, íî ó÷èòûâàòü èõ ïðè ïîñòðîåíèè òåõíîëîãè÷åñêîé ìîäåëè äåòàëè. Òàêèì îáðàçîì, ïðèìåíåíèå ñèñòåìû àíàëèçà ÒÊÈ îáåñïå÷èâàåò àäàïòàöèþ ìåòîäà ê çàäàííîìó ïðîèçâîäñòâó, àêêóìóëèðóÿ çíàíèÿ î òåõíîëîãè÷åñêîì áàçèñå ïðîèçâîäñòâà. Òåì ñàìûì îáåñïå÷èâàåòñÿ àäàïòèâíîñòü ìåòîäà â öåëîì, ó÷èòûâàþòñÿ ñóáúåêòèâíûå è îáúåêòèâíûå îñîáåííîñòè ïðîèçâîäñòâà. Ìåòîä ðàñïîçíàâàíèÿ ðàáîòàåò ñ êîíñòðóêòîðñêèìè ìîäåëÿìè, ïîñòðîåííûìè òâåðäîòåëüíûìè ïðèìèòèâàìè, ÷åì îáåñïå÷èâàåò èíâàðèàíòíîñòü ìåòîäèêè àíàëèçà ÒÊÈ ê ñïîñîáó ïîñòðîåíèÿ ìîäåëè. Áèáëèîãðàôè÷åñêèé ñïèñîê 1. 2. 3. 4. Àìèðîâ Þ. Ä. Òåõíîëîãè÷íîñòü êîíñòðóêöèè äåòàëè / Áèáëèîòåêà êîíñòðóêòîðà. Ì.: Ìàøèíîñòðîåíèå, 1990. 768 ñ. ÃÎÑÒ 14.201-83. Îáùèå ïðàâèëà îáåñïå÷åíèÿ òåõíîëîãè÷íîñòè êîíñòðóêöèè äåòàëè. Ì.: Èçäàòåëüñòâî ñòàíäàðòîâ, 1983. Êîëãàíîâ È.Ì., Äóáðîâñêèé Ï.Â., Àðõèïîâ À.Í. Òåõíîëîãè÷íîñòü àâèàöèîííûõ êîíñòðóêöèé, ïóòè ïîâûøåíèÿ. ×àñòü 1: Ó÷åáíîå ïîñîáèå. Óëüÿíîâñê: ÓëÃÒÓ, 2003. 148 ñ. Îñåòðîâ Â. Ã., Àìèðîâ Þ.Ä. Òåõíîëîãè÷åñêèé àíàëèç ìàøèíîñòðîèòåëüíîãî ïðîèçâîäñòâà. Ì.: Ìàøèíîñòðîåíèå, 1980. 205 ñ. ÂÅÑÒÍÈÊ ÌÀÈ. Ò.20. ¹1 !# Àâèàöèîííàÿ òåõíèêà Aircraft Engineering METHOD OF QUANTITATIVE ASSESSMENT OF THE AIRFRAME ELEMENT MANUFACTURABILITY Govorkov A.S. Irkutsk state technical university (National Research University), 83, Lermontov st., Irkutsk, 664074, Russia e-mail: govorkov_as@istu.edu n Abstract Purpose Nowadays element design is carried out with the help of CAD/CAM/CAE/PDM systems. Thus it is rational to estimate the manufacturability of element structure at early stages of product launch during element design and manufacturing. The goal of this paper is to provide a method for such evaluation. The paper considers a method of manufacturability calculation and estimation, which allows formalizing the process of airframe element manufacturability evaluation and altering characteristics and parameters of individual indicators. Design/methodology/approach While refining the airframe element design with the purpose of increasing the airframe manufacturability, one must take into account the manufacturing type and specific features of the manufacturer (manufacturing plant) so that structure of individual elements could be produced with taking the aforementioned factors into account. The paper proposes a method of quantitative estimation of airframe element structure manufacturability based on interaction of individual indicators with taking into account their weightcoefficients. Also an algorithm for manufacturability control of the element based on its 3D-model is suggested. Final assessment of industrial manufacturability is carried out according to single individual indicators by comparing the variants of the proposed element with analogues, which are already manufactured at the considered plant. The aggregated indicator value is determined under the conditions of an extremely unfavorable combination of individual indicators based on expert estimates. The quantitative assessment of element manufacturability during its design is carried out with the help of an aggregated indicator: !$ ÂÅÑÒÍÈÊ ÌÀÈ. Ò.20. ¹1 p= ∑ ki ϕi i =1 n ∑ ϕi , i =1 where ki is the value of manufacturability indicator i; individual element ϕi is the weight-coefficient of individual element manufacturability indicator i; n is the number of adopted indicators, which is defined by the expert and must be no less than 5. Weight-coefficients of the manufacturability indicators are determined by experts. Part of the indicators can be used again to evaluate other airframe elements while their weight-coefficients should be reidentified based on new expert estimates. Findings It is difficult and often impossible to fully estimate manufacturability level at early stages of manufacturing process design because of insufficient information. To ensure the structure manufacturability it is possible to make a qualitative assessment via manufacturability properties and carry out the quantified evaluation using individual indicators. The proposed method was tested on the example of structure design of sheet pressed airframe elements. It was discovered that this method does reflect the real conditions of structure design and manufacturing processes. Research limitations/implications The proposed method is based on expert estimations. Thus additional work is required for selecting the appropriate groups of experts to make these estimations less influenced by subjectivity of particular personalities. Originality/value Proposed methodology of refining the element structure manufacturability can be successfully applied in practice for calculation of manufacturability and Àâèàöèîííàÿ òåõíèêà estimation of the quality of the new developed airframe elements. This is especially important since it might be hard and/or impossible to carry out the manufacturability estimation for such elements according to the main indicators of the standards at the early stages of pre-production planning due to the lack of information, while the ability to carry out the estimation according to additional indicators is limited since such estimation would only reflect the structural design aspect. Technologies and methods of manufacturing design change over time. The proposed system of manufacturability analysis aspires to «isolate» the designer from such changes while still taking them into account during the creation of the model of the element manufacturing process. Application of structure manufacturability analysis provides for adaptation of the method to the specific manufacturing by accumulating knowledge about its technological basis. This ensures adaptability of the method as a whole and takes into account general and particular characteristic features of manufacturing. The recognition method works with structure models, which are based on solid-body primitives, thus ensuring the invariability of the manufacturability analysis method towards the way the model was built. Aircraft Engineering References 1. 2. 3. 4. Amirov Yu.D. Tekhnologichnost konstruktsii detali (Element structure manufacturability), Moscow, Mashinostroenie, 1990, 768 p. Obshchie pravila obespecheniya tekhnologichnosti konstruktsii detali, GOST 14.201-83 (GOST All-Union State Standard 14.201-83. Common rules of providing the element structure manufacturability, GOST 14.20183), Moscow, Standarty, 1983. Kolganov I.M., Dubrovskii P.V., Arkhipov A.N. Tekhnologichnost aviatsionnykh konstruktsii, puti povysheniya (Aircraft structure manufacturability and ways of its improvement), Ulyanovsk, UlGTU, 2003, part 1, 148 p. Osetrov V.G., Amirov Yu.D. Tekhnologicheskii analiz mashinostroitelnogo proizvodstva (Analysis of manufacturing technologies of machinery production), Moscow, Mashinostroenie, 1980, 205 p. Keywords: product model, manufacturability, airframe structure element, individual indicator of manufacturability, structure component. ÂÅÑÒÍÈÊ ÌÀÈ. Ò.20. ¹1 !%