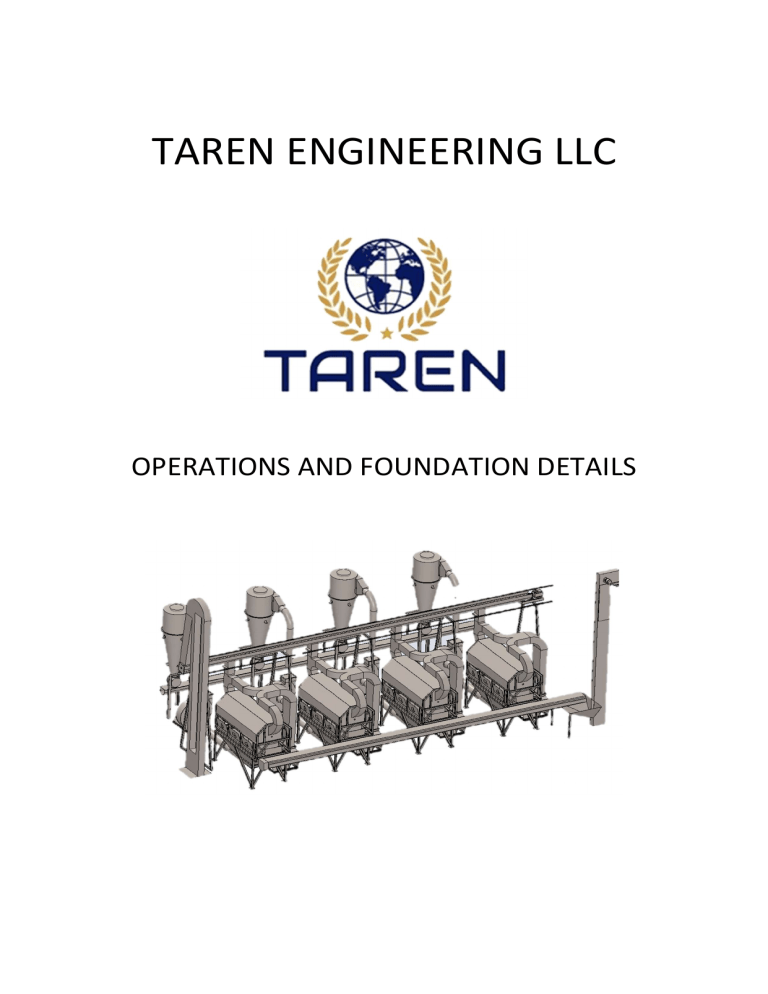

TAREN ENGINEERING LLC OPERATIONS AND FOUNDATION DETAILS SAFETY INSTRUCTIONS This document has been prepared to explain the technological process and capacities of the machines. The cotton seed delinting process is a process that requires precise adjustments. There are risk factors in these delintation machines. Delinter works with natural gas and sulfiric acid. Care must be taken while using them. cottonseed has a live embryo structure, it is extremely important to work in the right defaults. The commissioning of the plant and the first start process must be done with TAREN. CONTENTS 1)Reactor Bunker…………………………………………………………………………………… 1.1)Properties Table………………………………………………………………………………. 2)Chrome Reactor…………….…………………………………………………………………… 2.1) Properties Table……………………………………………………………………………… 3)Vertical Elevator…………………………………………………………………………………. 3.1) Properties Table……………………………………………………………………………… 4)Chrome Horizontal Helix…………………………………………………………………….. 4.1) Properties Table……………………………………………………………………………… 5)Taren1000 Delinter…………………………………………………………………………….. 5.1) Properties Table……………………………………………………………………………… 6)Cyclone and Fan System…………………………………………………………………….. 6.1) Properties Table……………………………………………………………………………… 7)Dust Collecting Helix…………………………………………………………………………… 7.1) Properties Table……………………………………………………………………………… 8) Neutralization Unit……………………………………………………………………………. 8.1) Properties Table……………………………………………………………………………… 1)Reaktor Bunker The machine which is storing the cotton seed from the screening and provides transition to the chrome reactor. There is one 5.5kW gearmotor and one capacitive sensor on the machine. İf capacity reachs the suitable capacity sensor works. Machine works with two type helix; first one has 200mm diameter and counterclockwise rotation second one has 300mm diameter and clockwise rotation. This case is designed for the regular flow of cottonseed inside the machine on the table1.1 Table1.1 1.1)Properties Table Material Capacity Size St37 10t/h d:4m, w:1.6m, h:3.7m Energy Consumption 5.5kW 2)Chrome Reactor The flowmeter is used to show and adjust the amount of acid solution to be mixed in the dew. The metal indicator inside the flowmeter shows the amount of solution given to the dew by moving up as you open the acid solution valve and down as you pinch it. In the treatment of seedlings with solution, factors such as the pile density of the seedling, the operating speed of the seedling, the solution given are interdependent and do not provide a constant value as they vary. An average treatment is given in the example below. Example: Pile density of the seedling (medium) + Processing speed of the seedling (300) + Solution (4.5): desired wet seed (moistened to the very tip of the seedling) The scale on the left side of the flowmeter is used. The machine, in which the cotton seed coming from the reactor bunker comes together with the acid solution, brings the cotton seed in the reactor bunker together with the acid and transmits it to the stainless elevator. There is one 11kW motor and one P5 İ:20 gear on the machine. Sulfuric Acid Tank Tank Pressurization A typical Sulfuric Acid (H2SO4) Tank should be pressurized to approximately 60 psi. A pressure gauge should be installed in the tank and a check valve is also installed to prevent back pressure or H2SO4 gases from entering into the main plant air lines. Fill/Drain Procedures A fill opening is located on the top front end of the tank. Refer to customer's drawings for precise location. The tank should be de-pressurized via the valve in the "vent line" before opening the fill inlet. A drain opening is located on the bottom front end of the tank. Refer to customer's drawings for precise location. The tank should be de-pressurized via the valve in the "vent line" before opening the fill inlet. ACID STORAGE TANK Acid Mix Tank Startup Water supply enters into the Acid Mix Tank through the 1" CPVC water inlet pipe. When approximately 70% of the Acid Mix Tank is filled, concentrated sulfuric acid (H,SO) is introduced into the Acid Mix Tank through the 1" CPVC acid inlet pipe. This acid amount is monitored by the Conductivity Meter/Analyzer. Acid should continue to enter the Acid Mix Tank until a mixture of 10%, by weight, solution of sulfuric acid is achieved. Mixing The mixing ratio for 10% sulfuric acid is approximately 400 pounds of water to 40 pounds of acid to 6 pounds of surfactant per 1 ton of cottonseed. This mixture is monitored by the Conductivity Cell, which is located at the lower side of the Acid Mix Tank. While the correct ratio of acid / water / surfactant is being added in the Acid Mix Tank, a 1/2 horsepower mixer continues to agitate the solution allowing for a complete and proper mixture. A sonic Level Sensor located at the top of the Acid Mix Tank reports the level of the acid mixture to the Conductivity Meter / Analyzer. The desired level of acid mixture can be programmed into the Level Sensor. The mixture exits the Acid Mix Tank through the side outlet and is filtered through a simplex basket strainer which is attached in line between the Acid Mix Tank and pump. The stainless steel acid pump pushes the mixture to the Acid Mix Supply Tank where the dilute acid mix solution is stored for use. ACID MIX TANK 8% ACID MIXTURE 1 US Gallon Water = 8.34595 pounds 1 US Gallon Acid = 15.02 pounds 1US Gallon Soap = 8.34595 pounds Based on 98% Sulfuric Acid (66 Be.) Surfactant Based on Tergitol NP-9 2.1)Properties Table Material Capacity Size Stainless Steel 316L 10t/h d:7.5m, w:0.53m, h:1m Energy Consumption 11kW 3)Chrome Vertical Elevator It does the vertical transport work between two different machines. It carries the acidic cotton seed coming from the chrome reactor to the chrome helix. 3.1)Properties Table Material Capacity Size Stainless Steel 316L 10t/h d:1.1m, w:0.25m, h:7m Energy Consumption 2.2kW 4)Chrome Horizontal Helix DELINTER UPPER VALVE It separates the cotton seed coming from the chromium reactor into the Taren 1000 Delinter machines. There are 300mm diameter chrome helix in the machine. Machine has flap valve and number of the valves are equals to number of Taren machines. When the machine reaches the appropriate capacity, the operator opens the valves from the control panel and cotton seeds enter the Taren 1000 Delinter machine. The operator checks the appropriate seed amount by looking at the loadcell system. After sufficient seed(1300kg) is taken, the operator closes the valves. The seeds inside the valves should be cleaned with air before the valves are closed. 4.1)Properties Table Material Capacity Size Stainless Steel 316L 7t/h d:0.5m, w:26m, h:0.75m Energy Consumption 3kW 5)Taren 1000 Delinter The main machine, which has a burner combustion system used for acidic delintation, meets the high temperature of the seed and is purified from excess such as crust. The filling capacity should be 1300kg of acidified cottonseed. Each machine has a 1M Btu 250,000 kcal capacity burner. It should run on natural gas or 100% propane. Delinter temperature should be set to a maximum of 55 degrees Celsius(Table5.1). After each tour, air must be cleaned from the lower cover. Delintir burner control valve inlet should be maximum 1 bar. The maximum working pressure of the machine is 20-25 bar. 1 hour after the filling (according to the moisture of the cotton seed), it is checked manually and visually through the delinter lower valve(table 5.2). Table 5.2 5.1)Properties Table Material Capacity Size St37 1t/h d:3.3m, w:1.6m, h:3.2m 6)Cyclone and Fan System Energy Consumption 7.5kW It takes part in the collection of wastes such as shell dust from the Taren 1000 Delinter machine by air suction method. The fan creates reverse current and acts as air suction. The accumulated dust is transferred to the waste transport helix with an airlock. 6.1)Properties Table Material Capacity Size St37 16.000m3/s d:1.1m, w:1.1m, h:5.2m Energy Consumption 30kW 7)Dust Collecting Helix It carries the waste dust from the cyclone horizontally to a place to collect it. 6.1)Properties Table Material Capacity Size St37 400 kg/s d:0.3m, w:15m, h:1.3m 8) Neutralization Unit Energy Consumption 3kW The seed is poured into this machine after the silo, it is the machine that adjusts the pH value of the seed. The machine that neutralizes the seed delinted with acid solution and brings the pH value between 4-6. the solution used is CaCO3 + H2O. When 100 kg of CaCO3 melts, it takes up 60 kg of space in the tank. 320 liters of water should be added for 100 kg of CaCO3. Amount of application to the seed: 7.5 kg of CaCO3 is used to obtain a pH of 4-6 per ton. 6.1)Properties Table Material Capacity Size Stainless Steel 316L St37 5t/s d:3.4m, w:1.8m, h:4.5m Energy Consumption 1.1kW