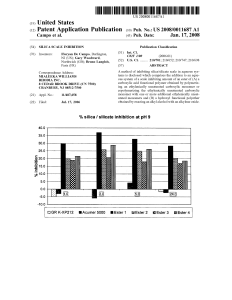

ACUMER™ WATER TREATMENT POLYMERS ACUMER™ 5000 Multipolymer for Silica and Magnesium Silicate Scale Control Cooling water reuse is frequently limited by a ceiling on the amount of tolerable silica in the recirculation water. Normally, if silica levels exceed about 180 ppm SiO2, severe scaling can occur on heat transfer surfaces. Moreover, the scale that forms is frequently difficult or impossible to remove by conventional means. ACUMER 5000 silica control polymer has now raised that ceiling to at least 300 ppm SiO 2, proven by exacting pilot studies and field trials, allowing for greater water reuse than ever before. ACUMER 5000 polymer prevents silica-based scale formation by dispersing colloidal silica and by preventing magnesium silicate scale formation at the heat transfer surfaces. The unique features of ACUMER 5000 polymer in the treatment of silica limited cooling water are presented below. Feature Your Benefit as a Service Company Your Customer's Benefit Maximum silica dispersancy and magnesium silicate scale inhibition. Increased cycles of concentration in silica-limited water. Reduced blowdown. Maintenance of clean heat transfer surfaces. Increased water reuse. Reduction in chemical use. Maintenance of process efficacy. Superior dispersant for particulates. Complete fouling control with a single dispersant. Less inventory required. Less risk of fouling due to changing conditions. Effective corrosion control when used with conventional corrosion inhibitors. No special formulating requirements. Longer plant lifetime. Chemically and thermally stable. Usable in single-package formulation. Simplified feed and control. © 2005 Rohm and Haas Company PHYSICAL PROPERTIES The typical physical properties of ACUMER 5000 polymer are listed in Table 1. TABLE 1 TYPICAL PHYSICAL PROPERTIES (these do not constitute specifications) Molecular Weight 5000 Total Solids, % 44.5 to 45.5 Active Solids, % 42 pH 2.1 to 2.6 Brookfield Viscosity, cp 700 max. Specific Gravity Bulk Density, lb/gal (g/cc) Lb (Kg) of 100% NaOH to neutralize 1 lb (kg) of polymer 1.2 10 (1.19) 0.131 Colloidal silica, which forms when the solubility level of silica is exceeded, is difficult to measure under field conditions, and a total silica mass balance cannot be achieved with a simple field test. The most effective method of determining total silica is described in “Standard Methods for the Examination of Water and Wastewater”, 17th edition (Method 4500-SiC). A simpler method that converts other forms of silica to molybdate-reactive silica is described in Rohm and sm Haas Technical Bulletin FC-267, “ACUMER TST , Total Silica Test for High-Silica Waters”. As the colloidal silica passes into the Nernst diffusion layer at the heat transfer surface, it dissolves and acquires a negative (anionic) charge. Polyvalent cations, especially magnesium, tend to react with these anionic colloidal particles effectively “gluing” them together and ultimately forming a hard, glassy magnesium silicate scale. FORMATION OF SILICA-BASED SCALE Silica forms particles with different structures depending upon the pH, presence of other ions and process by which the particles are formed. The three main forms of silica encountered in cooling water are: • Molybdate-reactive silica: frequently referred to as dissolved silica. • Colloidal silica: polymerized silica particles of 0.1 micron or less. • Silicate scale: primarily magnesium silicate, but may also be iron or calcium silicate. – 2 – Figure 1 shows how colloidal silica can dissolve to form silicate in the high temperature/high pH environment near a corroding cathodic surface where dissolved oxygen is reduced to hydroxide ions. These freshly formed silicate anions, added to the dissolved silica already present, can then form magnesium silicate scale (MgSiO3). In addition, colloidal silica alone can coprecipitate with magnesium hydroxide to form a scale of magnesium silicate having non-stoichiometric ratios of magnesium to silicate. FIGURE 1. MAGNESIUM SILICATE SCALE FORMATION 0.1 Micron Maximum HO HO HO O O O iO Si Si Si O S O O O O O O O SiOSi O Si • • • • • • • • • • • • • Si O SiOSi O O O O O O O O i Si Si Si OS O O O OH OH OH Bulk Water pH 8-9 Ca OH Mg Mg Mg Mg Mg Mg Mg Ca Mg Mg Nernst Diffusion Layer pH ~ 10 ~ 5 - 10 °C Higher Than Bulk Mg Fe+3 HO OH OH HO Fe Fe Fe Mg Mg Mg Fe Mg Mg Mg Mg Fe Mg Fe Mg OH HO Mg Fe Fe Composite Particle Mg/Ca/Fe/Silica HO Fe Mg Mg Mg Ca Mg HO - OH Mg Mg Mg OH Mg Fe Fe+3 OH Fe Fe+2 Anodic Area HO Cathodic Area MgSiO3 Scale Fe0 Mild Steel Surface – 3 – Mechanism for Controlling Silica The remarkable properties of ACUMER 5000 polymer derive in large part from its three distinctive functionalities. The weak acid (carboxylate) group provides a means of attaching the polymer to metal ions in solution and to the surfaces of particles or crystals. This enables the polymer to act as a dispersant to prevent agglomeration and deposit formation as well as stabilizing contaminants. The strong acid (sulfonate) contributes to this process by increasing the solubility and charge density of the polymer which enhances electrostatic repulsion of particles. What sets ACUMER 5000 polymer apart, however, is a unique third set of functionalities, based on balanced hydrophilicity and lipophilicity (hydrophobicity)1. Where the other functionalities operate primarily through charge-transfer, this so-called HLB functionality promotes physical adsorption on the surfaces of contaminant particles especially at higher temperatures. By promoting adsorption, this third type of functionality also contributes to the strength of the energy barrier (or the net repulsive force) created by the polymer around the silica particle. ACUMER 5000 polymer adsorbed on the colloid surfaces provides an energy barrier that prevents precipitation and agglomeration. Moreover, even if the silica particles precipitate, they are spaced too far apart for magnesium or redissolved silicate anions to bind them together. As a result, the scale formed by these particles will be powdery and, thus, easier to remove. For additional information on these mechanisms please request the following reprints: MAGNESIUM SILICATE SCALE PREVENTION WITH ACUMER 5000 POLYMER ACUMER 5000 Polymer Action in Recirculating Water Photomicrographs using cross-polarized lenses can be used to study crystal structures. Figure 3 shows the dispersed silica using ACUMER 5000 polymer in the recirculating water versus agglomerated silica particles in Figure 2 without polymer. FIGURE 2. DRIED FILM OF AGGLOMERATED SILICA PARTICLES WITHOUT POLYMER AT pH 9 Scale has large well-defined crystals typical of those found on cooler surfaces in cooling towers. FIGURE 3. DRIED FILM OF DISPERSED SILICA PARTICLES WITH ACUMER 5000 POLYMER AT pH 9 Hann, W. M. and Robertson, S.T. , “Control of Iron and Silica with Polymeric Dispersants”, IWC Paper No.90-29 (1990). Hann, W. M., Robertson, S.T. and Bardsley, J.H., “Recent Experience in Controlling Silica and Magnesium Silicate Deposits with Polymeric Dispersants”, IWC Paper No.93-59 (1993). 1The idea of enhancing adsorption by balancing hydrophilic and lipophilic moieties is borrowed from surfactant chemists who use the term HLB (hydrophile/ lipophile balance) to describe surfactant solubility and adsorption characteristics. Acumer 5000 polymer does not actually have surfacant-like properties, but it behaves in an analogous way. – 4 – Smaller dispersed “crystals” of colloidal silica. ACUMER 5000 Polymer Action at Heat Transfer Surface PERFORMANCE OF ACUMER 5000 POLYMER ACUMER 5000 silica control polymer also prevents formation of magnesium silicate under the conditions found near a heat transfer surface, as shown in Figures 4 and 5. Accelerated Pilot Cooling Tower Tests FIGURE 4. DRIED FILM OF MAGNESIUM SILICATE SCALE WITHOUT POLYMER PRESENT AT pH 10 A series of 3-day pilot cooling tower (PCT) tests were run to compare the dispersing efficiency of ACUMER 5000 polymer with that of conventional products. The water chemistry and operating parameters of the PCT in these studies are shown in Tables 2 and 3. TABLE 2 - MAKEUP WATER CHEMISTRY Si, as SiO2 50 ppm Ca, as CaCO3 60 ppm Mg, as CaCO3 90 ppm M-Alkalinity, as CaCO3 100 ppm Fe+3, as Fe 0.05 ppm TABLE 3 - AVERAGE OPERATING CONDITIONS Crystals are smaller but more numerous than in Figure 2, probably due to the presence of many small “magnesium silicate” particles. FIGURE 5. DRIED FILM UNDER SAME CONDITIONS AS IN FIGURE 4, BUT WITH ACUMER 5000 POLYMER PRESENT pH 9.0 ± 0.2 Cycles of Concentration (start-up) 4.5 Cycles of Concentration ( after 3 days) 6.8 to 7.5 Heat Flux 31,520 W/m2 Skin Temperature 105-120°F (41-49°C) Bulk Water Temperature 100°F (38°C) The treatment formulation used to evaluate polymer efficacy consisted of 2 ppm tolyltriazole (TTA), 10 ppm active polymer, and a 1/1 blend of 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTC) and 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP) to give 5 ppm total active phosphonate. At start-up, the formulation was fed into the system at three times the normal strength to compensate for the high concentrations of silica, calcium and magnesium. Crystals are very small and sparse due to polymer inhibition of magnesium silicate formation which seeds scale formation. – 5 – In these accelerated tests, water passed over a series of four heat transfer rods in succession. Scale formed on all four rods, with each developing more scale than its immediate predecessor. This progressive deposition was caused by the water becoming hotter as it passed over the rods in succession. As the water temperature rose, the tendency for deposits to form increased. In repeat tests, the amount of scale fluctuated dramatically when the polymer was an ineffective scale inhibitor. ACUMER 5000 polymer shows only a light dusting of scale (Figure 6), considerably better than the other polymers tested (Figures 7 and 8). Within the limits of experimental error, the scale compositions obtained with all tests were approximately the same, >80% magnesium silicate (Table 5). TABLE 5 - SCALE COMPOSITION (%) ACCELERATED PCT TESTS Dispersant Polymaleic Acid ACUMER 5000 POLYMER TABLE 4 - ACCELERATED PILOT COOLING TOWER TEST RESULTS Scale Component Dispersant Polymer Ca, as CaCO3 7.9 6.8 Mg, as CaCO3 52.2 50.8 Scale Formation, mg (total from 4 heat transfer rods) ACUMER 5000 850 Si, as SiO2 34.0 37.2 Polymaleic Acid >2,500 Fe, Fe2O3 0.4 2.6 Commercial silica control polymer P, as phosphonate* 5.5 3.1 >2,500 amorphous amorphous Crystalline form *expressed as 1/1 blend of HEDP/PBTC Photographs of the heat transfer rods during trial runs are shown in Figures 6 through 8. Each picture shows the second heater in the series after two days of the three-day experiment. FIGURE 6. HEAT TRANSFER ROD AFTER 2 DAYS—ACUMER 5000 POLYMER – 6 – FIGURE 7. HEAT TRANSFER ROD AFTER 2 DAYS—POLYMALEIC ACID FIGURE 8. HEAT TRANSFER ROD AFTER 2 DAYS— COMMERCIAL SILICA CONTROL POLYMER Long-Term Pilot Cooling Tests ACUMER 5000 polymer was compared to the two polymers from the previous trials in longer tests; 1) to determine whether concentrating the water too rapidly gave an artificial negative effect, 2) to analyze scale that might form in the cooler parts of the PCT, and 3) to measure the impact of the polymer on corrosion. These products were evaluated in the same water under the same conditions employed in the accelerated PCT tests (Tables 2 and 3); only the cycling rate and start-up conditions were different. In the long-term – 7 – trials, the water was started at 3 cycles of concentration (COC), using 2.5 times the normal treatment level, and then maintained at 5.5 COC (275 ppm SiO2) for four days to allow any silicate salts or silica to form, grow and precipitate. The water was then concentrated further to between 7.2 and 7.5 cycles of concentration over the next nine days of the test to reach a theoretical concentration of between 360 and 375 ppm SiO2 (50 ppm X 7.5). This quantity is approximately double the recommended maximum for cooling water. The results of these tests are given in Table 6. TABLE 6 – SCALE AND CORROSION ANALYSES LONG-TERM PILOT COOLING TOWER TESTS Dispersant Polymaleic Acid Total deposit weight, mg Corrosion rate, mpy Commercial Silica Control Polymer 1578.0 5.4 ACUMER 5000 Polymer 835.0 5.3 146.0 1.1 Approximate scale composition, %* cold side heat exchanger cold side heat exchanger cold side heat exchanger Si Ca Fe P Zn S Trace elements 25.1 6.5 47.5 7.4 0.4 10.5 2.6 52.0 16.1 17.9 6.5 2.8 1.0 3.7 0 1.1 98.9 0 0 0 0 47.5 16.5 27.6 4.3 0.3 0.9 2.9 0 1.5 98.5 0 0 0 0 60.4 16.8 10.3 9.1 0.4 0.3 0.7 *X-Ray fluorescence, excluding magnesium Note: cold side temperature = 102°F (39°C); heat exchanger temperature = 120°F (49°C) The results indicate that under the test conditions, ACUMER 5000 silica control polymer yields 10 times less silica-based scale than conventional polymaleic acid chemistry and 5 to 6 times less scale than the commercial silica control polymer. Moreover, the corrosion rate with ACUMER 5000 polymer is much lower than with the two other polymers. The large difference in corrosion rates may be due to underdeposit corrosion occurring with the less effective polymers. FIELD PERFORMANCE The benefits of ACUMER 5000 polymer have been substantiated by its performance in four field situations. In each instance, operators of the different facilities faced the problem of processing water that contained high silica levels and all overcame their difficulties by using ACUMER 5000 polymer in their cooling water treatment program. Chiller System Achieves 80% Increase in COC Plus On-Line Cleaning System Description: Two 250-ton cooling water units with a recirculation rate of 580 gpm were used to cool a high school. The units were treated with a chromate program until 1990. In March of 1990, the chromate treatment was replaced with molybdate/ zinc/phosphonate to comply with regulations against chromate. Deposits were controlled using 7-8 ppm active ACUMER 2000 copolymer. The pH of the system was maintained at 7.5 - 8.5. Problem: Total hardness of the makeup water was typically about 140 ppm, with a Ca/Mg ratio of about 1/1. The makeup water typically had about 45 ppm SiO2, and the system could only achieve about 2.5 cycles of concentration using the molybdate/phosphonate/zinc copolymer treatment. The condenser was opened in 1991 and found to have light scale containing about 25% silica with most of the balance being iron oxide. Solution: In one of the chiller systems, the copolymer was replaced with an equal concentration of ACUMER 5000 polymer and blowdown was reduced; all other variables remained the same. The other chiller system was maintained with the program containing ACUMER 2000 copolymer. – 8 – Results: The system treated with ACUMER 5000 polymer achieved more than 4.5 cycles of concentration with no silica drop-out. Early in this trial, the chemical feed was stopped accidentally; a subsequent drop in recirculating water SiO2 levels suggests that some scaling probably occurred. When the chemical feed was re-established, SiO2 levels temporarily increased to higher than expected levels, which leads to the conclusion that the ACUMER 5000 polymer had removed some of the scale. This also suggests that the dispersing action of the polymer, even when underfed, resulted in the formation of a powdery scale rather than the expected glassy magnesium silicate. The powdery nature of the scale would explain its apparent on-line removal. Data showed that over 200 ppm SiO2 had been attained in the recirculating water. Winery Increases Silica in Cooling Water Past Vintage Levels of 150 ppm SiO2 System Descripion: A northern California vineyard operates two 560-ton evaporative condensers using makeup water1 with high silica levels of 92 ppm SiO2. The cooling water system has a capacity of 18 gallons per minute with water temperatures ranging between 75°F (24°C) and 85°F (29°C). Problem: Initially, a stabilized phosphate program containing HEDP, phosphoric acid, tolyltriazole and an acrylate-type polymer was used. Scale formed on the evaporative condensers when silica levels exceeded 150 ppm SiO2 in the recirculating water. This deposit was found to contain high levels of silicon and magnesium. Results: Our customer replaced the existing polymer in his formulation with ACUMER 5000 polymer. This formulation was dosed into the system to maintain 13 ppm residual orthophosphate and 10-15 ppm active ACUMER 5000 polymer in the recirculating water. The recirculating water contains 400 ppm M-Alkalinity and had a pH between 8.5 and 8.7. The customer was able to increase cooling water cycles from 1.6 to 3 COC allowing up to 276 ppm SiO2 in the system. Thorough visual inspections, after 2 and 5 months, condenser tubes were free of scale. By switching to ACUMER 5000 polymer, this customer was able to cut his chemical usage by almost half and save 4 million gallons of water per year. 1 Make-up water analysis: pH 7.8, 138 ppm T-Alkalinity, 92 ppm SiO , 35 ppm Ca as CaCO , 11 ppm Mg, 2 3 7.4 ppm SO4, 18 ppm Cl, <0.1 ppm Fe, <0.3 ppm Mn, 270 ppm TDS. Cooling System Doubles COC in San Joaquin Valley, California System Description: Two evaporative condenser towers rated at 500 tons were used to cool a large computer computer facility. One tower was always kept as a backup to ensure continuous operation. The evaporative condensers consist of rows of tubes on the inside of the tower. The tower water cascades downward to directly contact the condenser tubes leaving a scale deposit if the water significantly exceeds the normal operating levels of about 180 ppm SiO2 and about 480 ppm (maximum) M-alkalinity. The original treatment used HEDP, benzotriazole and polymaleic acid with a supplemental feed of polyacrylic acid. Problem: The makeup water typically had 90-110 ppm SiO2, allowing only about 2 cycles of concentration. Due to severe drought conditions in this area for the previous 5 years, water was not readily available and had to be reused to the maximum extent possible. Solution: In 1991, the polymaleic acid and polyacrylic acid scale inhibitors used in the old treatment were replaced with an equal weight of ACUMER 5000 polymer. The treatment was fed to maintain the same levels as before, but the bleedoff was reduced. – 9 – Results: With ACUMER 5000 polymer, the system maintained up to about 4 cycles of concentration without scale or corrosion. Recirculation water has up to 300 ppm total silica and about 650 ppm M-alkalinity (maximum). Benefits of the reduction in bleedoff include: • A calculated 30% reduction in water usage under typical conditions. • A calculated 30% reduction in chemical usage. • An increase in holding time which allows the biocide to work more effectively (since the makeup water has a high organism count). Water Analysis: (at steady state) Makeup Recirculating Cycles of Concentration pH Conductivity, µmho M-Alkalinity, as CaCO3 Ca, as CaCO3 Mg, as CaCO3 Silica, as SiO2 7.8-8.1 330-360 154-180 60-80 56-80 60-70 8.9-9.0 1000-1030 536-540 236-264 260-268 265-300 — 2.9 3.2 3.6 3.9 4.2 Scale Problem Eliminated at Ice-Making Plant System Description: An ice-making plant with a refrigeration capacity of 270 tons had a history of scale problems, especially on the condenser coils. Silica levels in the makeup water were 46 ppm SiO2. System temperature ranged between 83°F (28°C) and 91°F (33°C). Problem: The water was treated with an all-organic program which left heavy deposits of silica. A thorough cleaning with ammonium bifluoride and hydrochloric acid was performed in the summer of 1992 to remove the heavy deposits. Between August and November of 1992, the COC were maintained at low levels (less than 2) to prevent silica scale. Under these conditions, CaCO3 still formed on the condenser coils, with head pressure on the condenser side measuring approximately 230 psi. Solution: ACUMER 5000 polymer was added to the system to maintain 15 ppm active polymer in the recirculationg water, and COC were gradually increased to 6 to 9. Results: By February of 1993, head pressure had dropped to the lowest level, 215 psi, indicating no scale. Theoretical silica levels approached 400 ppm SiO2. Ten months after changing the formulation to one containing ACUMER 5000 polymer, the plant continued to operate without problems. OTHER APPLICATIONS Boilers The superior hydrothermal stability of ACUMER 5000 polymer enables its use for controlling magnesium silicate scale in boilers operating up to about 600 psig (42 kg/cm2). Above 600 psig, it is recommended that the silica be removed from the feedwater by external treatment such as ion exchange. Reverse Osmosis The ability of ACUMER 5000 polymer to disperse colloidal silica as well as other particulates makes it suitable in formulations for fouling prevention in RO membranes used to treat high-silica water. – 10 – TOXICITY Toxicity data on ACUMER 5000 silica control polymer are presented in Table 7. TABLE 7 ANIMAL TOXICITY Acute Oral (LD50), rats Acute Dermal (LD50), rabbits Eye Irritation, rabbits Skin Irritation, rabbits >5 g/kg >2 g/kg Inconsequential irritation Practically non-irritating ENVIRONMENTAL TOXICITY Algae, 72-hour EC50 Daphnia magna, 48-hour EC50 Salmo gairdneri, 96-hour LC50 (Rainbow trout) 72.4 mg/l 1040 mg/l 1100 mg/l SAFE HANDLING INFORMATION Caution: For Industrial Use Only! Keep Out of Reach of Children! Wear chemical splash goggles and impervious gloves when handling. An approved respirator, suitable for the concentrations encountered, should be worn. FIRST AID INFORMATION Skin Contact Wash affected skin area thoroughly with soap and water. Consult a physician if irritation persists. Eye Contact Flush eye immediately with plenty of water for at cian if irritation persists. least 15 minutes. Consult a physi- Inhalation Move victim to fresh air. Ingestion If victim is conscious, dilute product by giving 2 glasses of water to drink and then call a physician. If victim is unconscious, call a physician immediately. Never give an unconscious person anything to drink. MATERIAL SAFETY DATA SHEETS Rohm and Haas Company maintains Material Safety Data Sheets (MSDS) on all of its products. These contain important information that you may need to protect your employees and customers against any known health and safety hazards associated with our products. We recommend you obtain copies of MSDS for our products from your local Rohm and Haas technical representative or the Rohm and Haas Company. In addition, we recommend you obtain copies of MSDS from your suppliers of other raw materials used with our product. Under the OSHA Hazard Communication Standard, workers must have access to and understand MSDS on all hazardous substances to which they are exposed. Thus, it is important that appropriate training and information be provided to all employees and that MSDS be available on any hazardous products in their workplace. Rohm and Haas Company sends MSDS on non-OSHA hazardous as well as OSHA-hazardous products to both “bill-to” and “ship-to” locations of all our customers upon initial shipment (including samples) of all of our products. Updated MSDS are sent upon revision to all customers of record. In addition, MSDS are sent annually to all customers of record. – 11 – For additional information, a sample, a Material Safety Data Sheet or to have a technical representative call for the nearest Rohm and Haas Office. THE AMERICAS EUROPE ASIA/ PACIFIC Corporate Headquarters Rohm and Haas Company 100 Independence Mall West Philadelphia, PA 19106 Phone:1-800-223-3897 Fax: 610-437-5212 France,Verneuil en Halatte Phone: 33-3-44-61-78-78 Fax: 33-3-44-34-79-60 Australia/ New Zealand Phone: 61-3-92724222 Fax: 61-3-92724211 France, Paris Phone: 33-1-40-02-50-00 Fax: 331-43-45-28-19 China, North Phone: 86-10-6464-3450-60 Fax: 86-10-6464-3466 Germany Phone: 49-69-78996-0 Fax: 49-69-7895356 China, South Phone: 86-757-3363-3708 Fax: 86-757-336-5478 Italy Phone: 39-02-95250-1 Fax: 39-02-95250399 India Phone: 91-11-464 7570 Fax: 91-11- 464 7683 Canada Phone: 416-284-4711 Fax: 416-284-2982 Brazil Phone: 55-11-5185-9000 Fax: 55-11-5182-5110 Mexico Phone: 525-728-6666 Fax: 525-728-6653 Japan Phone: 81-3-5488 3100 Fax: 81-3-5488 3179 Philippines Phone: 63-2-8925091/98 Fax: 63-2-8183908 Singapore/Malaysia Indonesia Phone: 65-7350855 Fax:65-7350877 Taiwan Phone: 886-2-2718-7090 Fax: 886-2-2713-3857 Internet Address: http://www.acumer.com or www.rohmhaas.com Thailand Phone: 66-2-6791030 Fax: 66-2-6791039 ACUMER is a trademark of Rohm and Haas Company, or of its subsidiaries or affiliates. The Company's policy is to register its trademarks where products designated thereby are marketed by the Company, its subsidiaries or affiliates. These suggestions and data are based on information we believe to be reliable.They are offered in good faith, but without guarantee, as conditions and methods of use of our products are beyond our control. We recommend that the prospective user determine the suitability of our materials and suggestions before adopting them on a commercial scale. Suggestions for use of our products or the inclusion of descriptive material from patents and the citation of specific patents in this publication should not be understood as recommending the use of our products in violation of any patent of the Rohm and Haas Company. FC-199b(A4) October 2005 Printed in U.S.A.