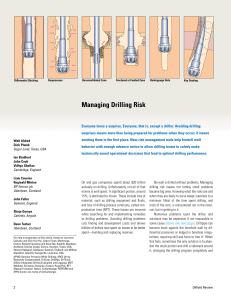

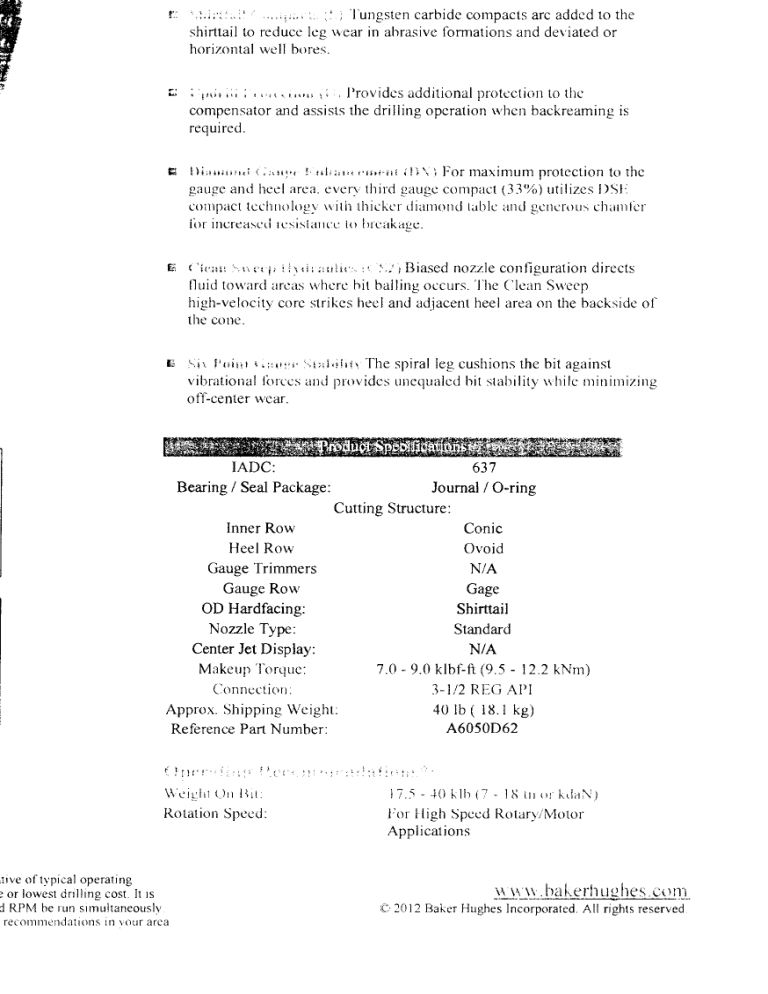

r.: .... ; Tungsten carbide compacts arc added to the shirttail to reduce leg wear in abrasive formations and deviated or horizontal well bores. * c ; |<>>>>i' ; . . Provides additional protection to the compensator and assists the drilling operation when backreaming is required. я ( liiHj1! !■ulrj.i.i .‘n.f-iii ; П V i For maximum protection to the gauge and heel area, every third gauge compact (3 3 % ) utilizes DSH compact technology w ith thicker diamond lab 1c and generous chamfer for increased lesisianee Io breakage. e ( Чет! Hu с; j, i:\ iii nulls':,: >,:) Biased nozzle configuration directs fluid toward areas where bit balling occurs. The ( ’lean Sweep high-velocity core strikes heel and adjacent heel area on the backside of the cone. и S i i i'o in i t S U ilo iH i The spiral leg cushions the bit against vibrational forces and provides unequaled bit stability while minimizing off-center wear. IADC: 637 Bearing / Seal Package: Journal / O-ring Cutting Structure: Inner Row' Conic Heel Row Ovoid Gauge Trimmers N/A Gauge Row' Gage OD Hardfacing: Shirttail Nozzle Type: Standard Center Jet Display: N/A Makeup Torque: 7.0 - 9.0 klbf-ft (9.5 - 12.2 kNm) Connection: 3-1/2 R E G A P I Approx. Shipping Weight: 4Ü lb ( 18.1 kg) Reference Part Number: A6050D62 W eight On Bli: 1 /.5 - 40 kill (7 - 1К til or k d a N ) Rotation Speed: fo r High Speed Rotary/Motor Applications ;tive of typical operating : or lowest drilling cost. It is d R P M be run simultaneously recommendations in vour area \Y\Yw .ha k e rh u Ühe s.CO m © 2012 Baker Hughes Incorporated. All rights reserved