5. Rheological properties of hydrate suspensions in an asphaltenic crude oil

реклама

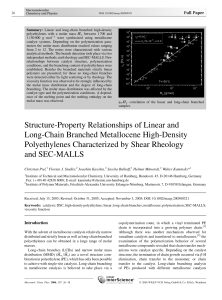

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/322603015 Rheological Properties of Hydrate Suspensions in an Asphaltenic Crude Oil Conference Paper · May 2002 CITATIONS READS 71 912 2 authors: Ricardo Camargo 9 PUBLICATIONS 164 CITATIONS Thierry Palermo TOTAL 40 PUBLICATIONS 1,073 CITATIONS SEE PROFILE SEE PROFILE All content following this page was uploaded by Ricardo Camargo on 23 January 2018. The user has requested enhancement of the downloaded file. ! "" Rheological Properties of Hydrate Suspensions in an Asphaltenic Crude Oil Ricardo Camargo (1) , Thierry Palermo (2) * (1) Petrobras (Brazil); (2) Institut Français du Pétrole (France) Rheological properties of hydrate suspensions in an asphaltenic crude oil were investigated. Two different experimental devices were used: a laboratory scale P-T cell adapted as a double coaxial cylinders rheometer and a 2” x 140 m flow loop. Hydrate suspensions exhibit shear thinning behavior and thixotropy, which can be interpreted as the result of a weak flocculation process between hydrate particles. A rheological model has been developed. In this model, the viscosity of the suspension is related to the size of aggregates, resulting from the balance between attractive forces and shear stresses. By comparison with experimental results, an estimation of the magnitude of attractive forces between hydrate particles is given. The origin of these forces is discussed. 1. Introduction When gas hydrates formation takes place in gas or oil production flow lines, hydrate plugs might form, leading to a complete blockage. A common practical process to remove such plugs consists in depressurizing or eventually heating the line to enable hydrate crystals to dissociate. In addition to safety hazards associated with these methods (Sloan, 2000) deep offshore oil production conditions makes their deployment difficult or impossible to achieve. Consequently, technical solutions rather consist in preventing hydrate plugs formation by insulating the lines or injecting chemicals. Mainly for economical reasons, insulation is today preferred for oil production by most of oil companies. In addition to standard prevention methods, the intrinsic capability of some crude oils to transport hydrate particles is today also seen as an interesting potential option. In the past, it was shown that chemicals, named dispersant additives, enable a stable W/O emulsion to form and then, once hydrate formation has occurred, allows the transportation of hydrates as a suspension of hydrate particles in the oil phase (Palermo et al., 1997). Polar compounds contained in crude oils, such as asphaltenes, are known to promote stable W/O emulsions (Førdedal et al., 1996) and are also suspected to further hydrates transportation (Leporcher et al., 1998). In this work, hydrate suspensions were formed in an asphaltenic crude oil under shear flow conditions. Their rheological properties were investigated with the help of two different devices: a laboratory scale P-T cell adapted as a double coaxial cylinders rheometer and a 2” x 140 m flow loop. In former papers (Camargo et al., 1999, 2000, 2001), results were presented and showed that such * Corresponding author. E-mail: thierry.palermo@ifp.fr hydrate suspensions exhibited shear-thinning behavior and thixotropy which can be interpreted as the result of a weak flocculation process between hydrate particles. In this paper, we present a rheological model, which relates the viscosity of the suspensions to the size of aggregates, resulting from the balance between attractive forces and shear stresses. By comparison with experimental results, an estimation of the magnitude of attractive forces between hydrate particles is given. The origin of these forces is discussed. 2. Experimental Devices Rheological Cell. The P-T rheological cell is able to work at a pressure of up to 9 MPa and with temperatures ranging from -15 to 65°C. It has a double coaxial cylinders geometry and works with imposed shear rate (or angular velocity) and measured torque. The angular velocity of the mobile cylinder ranges from 0 to 70 rad/s, while the torque is limited to 35 mN.m. The experimental procedure consisted in initially filling the cell with a W/O emulsion prepared as described in section 4. The pressure was then increased up to the working pressure (P=8 MPa). Hydrate formation was achieved by keeping the temperature at a fixed value inside the hydrate region (T=7.5°C) under shear conditions corresponding to a moderate angular velocity of 35 rad/s. Rheological behavior of the suspension was then investigated by varying the angular velocity and measuring the associated torque. A thorough description of this experimental device is given by Camargo et al. (1999). Flow loop. The so-called “Lyre loop, located at the IFP research center in Solaize, is 140 m long with an internal diameter of 2" and was designed to study “Flow Assurance” issues under multiphase flow conditions. The working temperature ranges from 0 to 50°C and the maximum pressure is 10 MPa. Fluid circulation is ensured by a positive displacement pump, that minimizes possible crushing of solid particles, for the liquid phase, and by a membrane compressor for the gas phase. More details about the Lyre loop can be found in reference (Palermo and Maurel, 2000). Emulsion was formed under pressure and multiphase flow conditions. Hydrate formation was achieved by cooling the fluids at a temperature lower than 5°C, at a constant pressure of 7.5 MPa at the outlet extremity of the flow line. Rheological behavior of the suspension was then investigated at a temperature of 7.5 °C under liquid flow conditions (Camargo et al., 2000). 3. Fluids composition The crude oil comes from a Brazilian deep-water field and was provided by Petrobras. The main properties of the dead crude oil in terms of viscosity, density and SARA analysis are given in Table 1. Asphaltenes are defined as the n-heptane insoluble fraction of the oil. Density at 15 °C kg/m3 914 Viscosity at 20 °C cp 135 Saturates % weight 50 1 Aromatics % weight 30 1 Resins % weight 15 2 Asphaltenes % weight 5 1 Table 1: Properties of the dead crude oil Viscosity of the live crude oil (dead crude oil saturated with gas under pressure) is given in Table 2. T = 7.5 °C T = 12 °C T = 25 °C 60 10 44 5 20 2 0 (cp) Table 2: Viscosity of the live crude oil at P=7.5 MPa In the rheological cell, the gas phase was composed of 90% molar of methane and 10% molar of ethane. In the flow loop, the gas phase was a natural gas delivered from the gas network. The molar fractions were typically in the range 92%-95%, 3%-5% and >1% for C1, C2 and C3+, respectively. In both cases, structure II hydrates are expected to form. However, coexistence of structure II and structure I may exceptionally be encountered depending on pressure and temperature conditions (Ballard and Sloan, 2001). The water phase was salted water (33 g/l NaCl). 4. Emulsion Stability W/O emulsions were investigated under ambient conditions (atmospheric pressure, temperature of 20 °C). They were prepared by agitating the dead crude oil with a high shear mixer Ultra-Turrax T25 running at 8,000 rpm for 180 seconds, while slowly pouring the water on it. Three water contents: 15 wt%, 30 wt% and 50 wt%, were investigated. Observation, focused on the appearance of a free water phase, indicated that emulsions remained very stable over a period of several months. Emulsions were also prepared, at a water content of 30 wt%, with three fractions removed from the crude oil: saturates + aromatics, resins and asphaltenes. For the oil containing only saturates and aromatics, the emulsion is not stable and a free water phase was rapidly visible, leading to a complete phase separation after some minutes. For the oil phase corresponding to 1wt% of resins in toluene, a small quantity of free water phase appeared after some minutes. For the last system, 1 wt% of asphaltenes in toluene, a stable emulsion was formed and no free water was visible after a period of several days. That confirms, for the crude oil investigated in this study, that asphaltenes are the major oil components acting as natural surfactants. Size of water droplets was determined by optical microscopy. Droplet diameters have been measured in the range of 0.5 to 3 m. Size of water droplets was also determined for emulsions sampled from the rheological cell and the flow loop, before hydrate formation as well as after hydrate dissociation. No significant change in size has been noticed. 5. Rheological Behavior of Hydrate Suspensions The crude oil showed a very good capability in transporting hydrate particles as a suspension and made rheological investigations feasible. As presented in previous papers (Camargo et al., 1999, 2000), shearthinning and time-dependant (thixotropy) properties were observed for hydrate suspensions for a volume fraction of 0.27 and above. On the other hand, suspensions formed at a volume fraction of 0.134 behaved roughly like a Newtonian system. Shear-thinning behavior is frequently observed for concentrated suspensions. This phenomenon, particularly when it is associated with a thixotropic behavior, is generally attributed to a reversible aggregation process that takes place between particles under shear flow. The main questions therefore concern the type of force of interaction involved in this aggregation process, as well as its order of magnitude. In the following, a phenomenological model is proposed to explain the non-Newtonian behavior of hydrate suspensions formed with this crude oil. 6. Phenomenological Model Basic Assumption. Hydrate crystals are expected to form at the water-oil interface. Thus, a solid shell forms around water droplets making them behave as solid particles. In the following, hydrate particles will be assumed to be spherical, with an identical diameter as water droplets. Viscosity of concentrated suspensions. Numerous equations have been developed in order to relate viscosity of concentrated dispersions to particle concentrations. These equations are generally expressed as a relationship between the relative viscosity r and the couple ( max). The relative viscosity is the ratio between the apparent viscosity of the suspension and the viscosity of the dispersing liquid 0. is the particle volume fraction and max is physically interpreted as the maximum volume fraction to which particles can pack. In this work, we will use the equation proposed by Mills (1985), well adapted to hard spheres of equal size and accounted only for hydrodynamic interactions: 1 Eq. 1 µr ; max 4 2 7 1 considering a mechanism of destruction based on the erosion of microflocs (Mühle, 1993), the maximum size of aggregates for laminar flow is given by: Eq. 5 where Viscosity of concentrated aggregated suspensions. Several theoretical models have been proposed in the literature to describe the growth of particle clusters either by perikinetic aggregation (caused by Brownian motion) or by orthokinetic aggregation (caused by medium flow) (Jullien, 1990; Potanin, 1990). The porosity of the resulting aggregates is taken into account by introducing a fractal dimension f, relating the number of particles N per fractal aggregate to characteristic lengths of the system (dA: aggregate diameter; dp: particle diameter): N dA dp Due to the fractal structure of aggregates, it has been proposed that an effective particle volume fraction eff should be considered instead of the real volume fraction in the expression for the viscosity (Mills, 1985): 1 eff Eq. 3 µr ; max 4 2 7 eff 1 max with 3 f Eq. 4 eff 1 4 f µ0 In Eq. 5, the shear stress exerted to aggregates is related to the viscosity 0 of the dispersing liquid. It is only correct when aggregates do not interact, i.e., 0. However, for finite , hydrodynamic interaction of aggregates can be taken into account, as proposed by Potanin (1990), by substituting in Eq. 5 the viscosity 0 by the apparent viscosity of the suspension . Finally, we have: 1 Eq. 6 Fa d p d A, max 2 f 4 f µ At the equilibrium, we consider that dA dA,max. Combining Eq. 3, Eq. 4 and Eq. 6, dA/dp can be determined by solving the following equation: Eq.7 dA 4 f dp Fa 1 2 dp µ 0 1 dA max dA 3 f 2 dp 3 f 0 dp If the solution of Eq.7 is dA/dp <1, dA is fixed equal to dp. The relative viscosity is then determined by using Eq. 1. 7. Results f Eq. 2 d A,max 2 f is the shear rate. max max is taken as the packing concentration of randomly packed spheres of same diameter. Fa d p dA dp It is well accepted that the fractal dimension, for perikinetic aggregation , ranges from about 1.7 to 2.1. Under shear conditions, it is generally reported that aggregates are more compact with fractal dimension larger than 2 and up to 2.7 (Hoekstra et al, 1992). Because of viscous forces applied on aggregates in the flow, they cannot growth indefinitely. A maximum size is reached depending on the balance between the shear stress and the force of adhesion Fa between particles. By Comparison between model and experiment. Results obtained from the phenomenological model are compared in with some experimental results obtained for hydrate suspensions formed with the asphaltenic crude oil. Except for the force of attraction Fa, all the parameters have been set to their assumed or measured value. According to the discussions above, the fractal dimension has been set to f = 2.5, the maximum packing concentration to max = 4/7, and the particle diameter to dp = 1.5 m. Recall that the viscosity of the continuous oil phase at 7.5°C is 0 = 60 cP. Experimental results are presented for two particle volume fractions : = 0.134 and = 0.274. Higher volume fractions were also investigated. However, as it is frequently observed for suspensions at high volume fraction, a slip effect has been experienced. This phenomenon will not be discussed in this paper. Due to time-dependant properties of suspensions, only results obtained during the increase of the shear rate are shown. Indeed, it is expected that the destruction of aggregates is a more rapid process than formation. Consequently, the relative viscosity measured under such conditions is probably closer to the equilibrium state than the one measured during a decrease of the shear rate. Results of calculation presented in, correspond to a force of attraction : Fa = 1.2 nN. Expressed with respect to the radius of curvature of the surface R, we have Fa/R =1.6 mN/m, with R = dp/2. reported. Corresponding experimental data obtained in the loop for = 0.134 and 0.274 are also reported. 200 180 = 0.274 160 140 120 0 = 0.0706 Pa.s = 57.66 Pa 100 40 80 35 60 40 30 = 0.274 25 0 = 0.0724 Pa.s = 6.72 Pa = 0.134 20 0 20 0 100 200 300 400 Shear Rate (1/s) 15 10 = 0.134 5 0 0 100 200 300 400 500 600 700 800 Shear rate (1/s) Figure 1: Comparison between calculation and experimental data obtained for hydrate suspensions in the asphaltenic crude oil. Lines: calculated from the model; marks: experimental data obtained in the loop ( ) and in the cell (x). Globally, the evolution of the relative viscosity with the shear rate, depending on the particle volume fraction, is well described by the aggregation model. At low volume fraction ( = 0.134), calculation indicates that the increase of the relative viscosity should be only significant at low shear rates (below 50 s-1). Experimentally, in the range of shear rates investigated (50 to 600 s-1) neither shear-thinning nor thixotropic behavior have been observed. At = 0.274, we have a good agreement between calculation and experimental data with the shear-thinning behavior well described. Rheological behavior. As analytically demonstrated by Mills (1985) in the particular case of a fractal dimension f = 2, the rheological behavior of an aggregated suspension can be described by a Casson’s like equation : 1 1 1 2 2 2 Eq. 8 0 where is the shear stress, 0 the yield shear stress, and a function of Fa, dp, and From the calculated viscosity, it is possible to deduce the corresponding shear stress . By fitting the calculated values of with an equation of the form of Eq. 8, the yield shear stress 0, as well as , can be determined. For simplicity, has been taken as a constant that depends only on the volume fraction. Figure 2 shows results of such a calculation for the two volume fractions = 0.134, 0.274. Values of the calculated yield shear stress 0 and the constant are Figure 2: Rheological behavior of hydrate suspensions in the asphaltenic crude oil. Corresponding Casson’s law = 0.137 and 0.274. (O): theoretical values of for determined from the viscosity ; lines: fitted Casson’s law; ( ): experimental loop data. 8. Forces of particles interaction between hydrate Previous calculations have been performed with a force Fa/R = 1.6 mN/m. For a better understanding of physicochemical properties of hydrate suspensions, it is interesting to know the origin of forces involved in hydrate particles interaction for this system. Stability of colloidal systems is often explained through the well-known DLVO theory, which takes into account the van der Waals forces and the electrostatic (or doublelayer) forces. Since, in our case, the continuous phase is organic, it is expected that repulsion electrostatic forces are negligible. On the other hand, van der Waals forces (attractive forces for identical particles) always exist in disperse systems. The van der Waals forces between two spheres of same radius R is given by the relation (Israelachvili, 1992a): AR Eq. 9 Fa 12D 2 where A is the Hamaker constant and D the distance which separates the two spheres. The Hamaker constant is related to the dielectric constant and the refractive index n of the different media (explicit formula can be found in Israelachvili, 1992a). Let us set down for the hydrate phase: 58 (Makogon, 1997) and n 1.35 (Herri & Gruy., 1995), and for the hydrocarbon liquid phase: 2 and n 1.45 (Israelachvili, 1992a). We obtain for the Hamaker constant: A 5.2 x10-21 J. Simple calculation shows that van der Waal attractive forces between hydrate particles in a oil phase become significant below a distance of the order of 1 nm (D>1nm Fa/R<<0.5mN/m). Such a small distance of separation is unlikely to be achieved because asphaltenes contained in the crude oil are expected to adsorb on particles, pushing away particles to larger distances. Even if we consider that no asphaltenes are adsorbed, the roughness of particle surface should be thinner than 1 nanometer, which is difficult to imagine. Thus, we suggest that, due to adsorption of asphaltenes, interactions between hydrate particles in the asphaltenic crude oil may be similar in nature to the ones encountered between polymer-covered surfaces (Israelachvili, 1992b): repulsive steric, attractive intersegment and bridging forces. Such interactions have been highlighted for crude oils by Christenson and Israelachvili (1987) with the help of a Surface Forces Apparatus (S.F.A.). Surface forces were measured between two cylindrically curved mica surfaces immersed in an asphaltenic crude oil. The authors measured forces of attraction in the range: Fa/R 5mN/m to Fa/R 0.5mN/m, associated with hard wall distances from D 3 nm to D 5 nm. Such forces are typically of the same order of magnitude as the one we have determined in the present work. 9. Discussion and Concluding Remarks In this work we have dealt with hydrate suspensions once the hydrate formation stage is completely achieved. Despite no direct observation has been performed, we propose that asphaltenes adsorbed on the hydrate particle generate an attraction force between hydrate particles. The magnitude of this force is of the order: Fa/R 1mN/m. This attraction force leads to a reversible aggregation process, responsible for the shear thinning behavior and the thixotropy shown by the suspensions analyzed. Van der Waals forces seem to be negligible, even for nude particles. It would confirm, as frequently reported by the hydrate community, that hydrate plug formation is seldom observed once hydrate formation is completed and hydrate particles are well dispersed in the oil phase. Thus, as Austvik (1999) reported, “A system in which most of the water has been converted into hydrates normally forms a fine powder that is easily transported in HC liquids”. On the other hand, the risk of plug formation mainly occurs during the hydrate formation process. Consequently, other forces should exist during this stage, making hydrate particles “sticky”. As a result of the expected high hydrophilic character of hydrate surface, it is believed, as suggested by Austvik (1999), that capillary forces are responsible for the agglomeration process between hydrate particles. During the hydrate formation stage, hydrate and liquid water phases co-exist in the hydrocarbon liquid phase. Water bridges can form between the hydrate particles, generating attractive capillary forces. A simple calculation, using the expression (Israelachvili, 1992c): Eq. 10 Fa 2 R WO cos with a contact angle = 0 (high hydrophilic hydrate surface) and an interfacial tension WO 10 mN/m, shows that capillary forces would be of the order: Fa/R > 50 mN/m. This value is quite high when compared with polymer-like forces (Fa/R 1 mN/m) and van der Waals 0.1 mN/m). Attraction forces of that forces (Fa/R magnitude can easily explain plug formation during the hydrate formation process. Moreover, water bridges may be converted into hydrate bridges, resulting in a nonreversible aggregation process. Once the hydrate formation process is completed, there is no longer free water available to generate capillary forces. Therefore, wettability properties of hydrate crystals during the formation process seem to be the dominating factor concerning plug formation. In the systems analyzed in the present work the adsorption of asphaltenes probably made hydrate particles more hydrophobic, thus preventing the agglomeration process between particles during the hydrate formation process. Acknowledgments This work has been performed within a collaboration program involving IFP, PETROBRAS and TOTALFINAELF. The authors would like to thank these companies for their financial support and for permission to publish these results. References Austvik, T., Xiaoyun. L., & Gjertsen, L.H. (1999). Hydrate plug properties: Formation and removal of plugs. Proceedings of the 3rd International Conference on Gas Hydrates. Salt Lake City, Utah, USA. Annals of the New York Academy of Sciences, 2000, Vol. 912 (G.D. Holder & P.R. Bishnoi, Ed.), pp. 294-303. Ballard, A.L., & Sloan, E.D. Jr (2001). Hydrate phase diagrams for methane + ethane + propane mixtures. Chemical Engineering Science, 56, 6883-6885. Camargo, R., Palermo, T., Maurel, P., & Bouchard, R. (2000). Flow properties of hydrate suspensions in asphaltenic crude oil. Proceedings of the 2d International Conference on Petroleum Phase Behavior and Fouling, Copenhagen, Denmark. Camargo, R., Palermo, T., Sinquin, A., & Glénat, P. (1999). Rheological characterization of hydrate suspensions in oil dominated systems. Proceedings of the 3rd International Conference on Gas Hydrates. Salt Lake City, Utah, USA. Annals of the New York Academy of Sciences, 2000, Vol. 912 (G.D. Holder & P.R. Bishnoi, Ed.), pp. 906-916. Camargo, R. (2001). Propriétés rhéologiques de suspensions d’hydrate dans des bruts asphalténiques, PhD thesis, University Paris VI, Paris. Christenson, H.K. and Israelachvili, J.N. (1987). Direct measurements of interactions and viscosity of crude oils in thin films between model clay surfaces, Journal of Colloid and Interface Science, 119 (1), pp. 194-202. Førdedal, H., Midttun, Ø., Sjöblom, J., Kvalheim, O.M., Schildberg, Y., & Volle J.L (1996). A multivariate screening analysis of W/O emulsions in high external electric fields as studied by means of dielectric time domain spectroscopy, II: Model emulsions stabilized by interfacially active fractions from crude oils. Journal of Colloid and interface Science, 182, 117-125. Herri, J.M., & Gruy, F. (1995). Calculation of the index of refraction of pure hydrate gas using a modified Lorentz-Lorentz model: application to methane hydrate, Materials Chemistry and Physics, 4, pp. 54-55. Hoekstra, L.L., Vreeker, R., & Agterof, W.G.M. (1992). Aggregation of colloidal nickelhydroxycarbonate studied by light scattering. Journal of Colloid and Interface Science, 151, (1), pp. 17-25. Israelachvili. J. (1992a). Van der Waals Forces between Surfaces. In Intermolecular & Surface Forces, 2nd ed., Academic Press. Chapter 11. Israelachvili. J. (1992b). Steric and Fluctuation Forces. In Intermolecular & Surface Forces, 2nd ed., Academic Press. Chapter 14. Israelachvili. J. (1992c). Adhesion. In Intermolecular & Surface Forces, 2nd ed., Academic Press. Chapter 15. Jullien, R. (1990). The application of fractals to investigations of colloidal aggregation and random deposition. New journal of chemistry, 14, no 3, pp. 239-253 Leporcher, E., Peytavy, J.L., Mollier, Y., & Sjöblom, J. (1998). Multiphase transportation: hydrate plugging prevention through crude oil natural surfactants. Proceedings of the Annual Technical Conference and Exhibition, New Orleans, USA. SPE 49172. Makogon Y.F. (1997): Hydrates of hydrocarbons, PennWell Publishing Company, Tulsa, Oklahoma. pp. 100. Mills, P. (1985). Non-Newtonian behaviour of flocculated suspensions. Journal de Physique Lettres, 46, L301-L309. Mühle, K. (1993). Floc stability in laminar and turbulent flow. In Coagulation and Flocculation: Theory and Applications (B. Dobias, Ed.). Surfactant Science Series, vol. 47, Chap. 8. Palermo, T., Sinquin A., Dhulesia H., & Fourest J.M. (1997). Pilot loop tests of new additives preventing hydrate plugs formation. Proceedings of the 8th International Conference on Multiphase97 (A.P. Burns, Ed.), BHR Group Conference Series, Cannes, France. pp. 133-147. Palermo,T. & Maurel, P. (2000). Investigation of hydrate transportation with and without dispersant additives under multiphase flow conditions. Proceedings of ETCE/OMAE2000 Joint Conference: Energy for the New Millenium, New-Orleans, USA. Potanin, A.A. (1990). On the mechanism of aggregation in the shear flow of suspensions. Journal of Colloid and Interface Science, 145 (1), pp. 140-157. Sloan, E.D. Jr (2000). Safety First: A Gallon of Prevention Is Worth a Mile of Cure. In Hydrate View publication stats Engineering (J.B. Bloys, Ed.), Monograph Volume 21, SPE, Henry L. Doherty Series. Chapter 1.