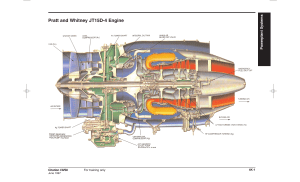

МИНИСТЕРСТВО ТРАНСПОРТА РОССИЙСКОЙ ФЕДЕРАЦИИ ФЕДЕРАЛЬНОЕ АГЕНТСТВО МОРСКОГО И РЕЧНОГО ТРАНСПОРТА ФГБОУ ВО «СИБИРСКИЙ ГОСУДАРСТВЕННЫЙ УНИВЕРСИТЕТ ВОДНОГО ТРАНСПОРТА» 81.2Англ С 347 И.А. Сидорова Иностранный язык DIESEL ENGINE Дизельный двигатель Учебное пособие Новосибирск 2020 81.2Англ С 347 Сидорова Ирина Анатольевна. Иностранный язык. Diesel engine. Дизельный двигатель: учебное пособие / И.А. Сидорова. – Новосибирск: Сиб. гос. унив. водн. трансп., 2020. ISBN 978-5-8119-0851-6 Данное пособие предназначено для студентов 2-3 курса специальности «Эксплуатация судовых энергетических установок» по дисциплине «Иностранный язык». Пособие разработано на основе компетентностного подхода к обучению иностранному языку для специальных целей и с учетом принципа взаимосвязанного обучения всем видам речевой деятельности на профессионально-ориентированном материале. В основе пособия тематический принцип подачи текстового материала. Пособие ставит целью овладение лексическим и терминологическим словарем в профессиональной сфере, обучение различным видам чтения литературы по специальности, а также развитие умений и навыков устной речи, аннотирования и реферирования. Пособие разработано на основе аутентичных текстов и содержит разговорные темы, тренировочные упражнения, диалоги, тексты для дополнительного чтения, тестовые задания, список сокращений, используемых в современной литературе по судомеханике. Рекомендовано в печать редакционно-издательским советом ФГБОУ ВО «СГУВТ» 23.06.2020 протокол № 42. Сидорова И. А., 2020 ФГБОУ ВО «СГУВТ», 2020 UNIT I TYPES OF MARINE ENGINES ТИПЫ МОРСКИХ ДВИГАТЕЛЕЙ Vocabulary blade brake horsepower (bhp) to drive лопатка (турбины) тормозная мощность вращать, приводить в движение; привод gearing зубчатая передача (привод) friction трение internal combustion engine двигатель внутреннего сгорания maintenance ремонт, эксплуатация medium-speed engine среднеоборотный двигатель nuclear plant атомная силовая установка oil fuel жидкое топливо rather than а не, скорее чем rpm (revolutions per min- обороты в минуту ute) piston поршень to put out вырабатывать (энергию) power output мощность (выходная, на выходе, генерируемая) shaft вал via через, посредством efficiency КПД to reduce сокращать, снижать size размер weight вес to attach прикреплять conventional обычный, стандартный decay распад There are four main types of marine engines: the diesel engine, the steam turbine, the gas turbine and the marine nuclear plant. Each type of engine has its own particular application. The diesel engine is a form of internal combustion engine. Its power is expressed as brake 3 horsepower (bhp). This is the power put out by the engine. Effective horsepower is the power developed by the piston in the cylinder, but some of this is lost by friction within the engine. The power output of a modern marine diesel engine is about 40,000 brake horsepower. This is now expressed in kilowatts (kwts). By comparison the engine of a small family car has an output of about 80 bhp. Large diesel engines, which have cylinders nearly 3 ft in diameter, turn at the relatively slow speed of about 108 rpm. These are known as slow-speed diesel engines. They can be connected directly to propeller without gearing. Although higher power could be produced by higher revolutions, this would reduce the efficiency if it is larger and if it turns slower. These large slow running engines are used in large merchant ships particularly in tankers and bulk carriers. The main reason is their low fuel consumption. More and more of the larger merchant vessels are being powered by medium-speed diesel engines. These operate between 150 and 450 rpm, therefore they are connected to the propeller by gearing. They are cheaper than slow-speed diesel engines, and their smaller size and weight can result in a smaller cheaper ship. In steam turbines high pressure steam is directed into a series of blades attached to the shaft, causing it to rotate. This rotary motion is transferred to the propeller shaft by gears. Steam is produced by boiling water in a boiler, which is fired by oil. Recent developments in steam turbines which have reduced fuel consumption and raised power output have made them more attractive as an alternative to diesel power in ships. They are 50 percent lighter and on very large tankers some steam turbines can be used to drive the large cargo oil pumps. Turbines are often used in container ships, which travel at high speeds. Gas turbines are known to differ from steam turbines in that gas rather than steam is used to turn a shaft. These have also become more suitable for use in ships. Many naval vessels are powered by gas turbines and several container ships are fitted with them. A gas turbine engine is very light and easily removed for maintenance. It is also suitable for complete automation. Nuclear power in ships has mainly been confined to icebreakers. A nuclear-powered ship differs from a conventional turbine ship in that it uses the energy released by the decay of radioactive fuel to 4 generate steam. The steam is used to turn a shaft via a turbine in the conventional way. EXERSISES Ex.1. Give Russian equivalents for the following. Internal combustion engine, brake horse power (bhp), low fuel consumption, high pressure steam, rotary motion, propeller shaft, power output, to reduce fuel consumption, to raise power output, complete automation, nuclear power ship, conventional turbine ship, oil-fired boiler, to generate steam, to release energy, to drive oil pumps, to turn a shaft, to cause rotation. Ex.2. Say it in English. выделять энергию, снижать КПД / эффективность, малооборотный дизельный двигатель, соединять с винтом с помощью редуктора, направлять пар на лопатки, производить пар, передавать вращательное движение на вал, вырабатывать пар, увеличивать/ снижать мощность, приводить в движение, оснащать чем-либо. Ex.3. Match the English words in A with their Russian equivalents in B. A 1) power 2) without gearing 3) nearly 3 ft 4) propeller 5) as well as 6) modern engine 7) particularly 8) reduce 9) pump 10) steam engine 11) fast cargo liner 12) main reason 13) slow speed 14) maintenance B 1) небольшая скорость 2) быстроходное грузовое судно 3) без привода (зубчатой передачи) 4) мощность 5) почти 3 фута 6) так же, как и 7) винт 8) основная причина 9) эксплуатация 10) особенно 11) паровой двигатель 12) насос 13) современный двигатель 14) снижать 5 Ex.4. Answer the questions. 1. What are the main types of marine engines? 2. What is a diesel engine? 3. How is the power of the diesel engine expressed? 4. What are characteristics of low-speed engines? What is their main advantage? 5. What kind of engines (slow, medium or high speed) are installed on large merchant vessels in most cases today? What are their main characteristics? 6. What kind of vessels use steam turbines for propulsion today? 7. What makes them so preferable? 8. Where does the difference between gas turbines and steam turbines lie? 9. What types of ships are equipped with nuclear power plant? Ex.5. Translate into English paying attention to the Passive constructions (to be + Participle II) Model: Турбины часто используют(ся) на контейнерных судах. Turbines are often used in container ships. 1. Часть мощности теряется из-за трения. 2. Мощность выражается в киловаттах. 3. Малооборотный (дизельный) двигатель соединяется (соединен) прямо на винт без редуктора. 4. Он называется двигателем с прямым соединением на винт. 5. Все больше торговых судов оснащается (оснащено) среднеоборотными двигателями. Они соединяются с винтом с помощью редуктора. 6. В паровых турбинах пар высокого давления направляется на ряд лопаток, прикрепленных к валу. 7. Вращательное движение (вала) передается на гребной вал с помощью редукторов. 8. Расход топлива в современных паровых турбинах уменьшен, а мощность увеличена. 9. Газовая турбина очень легкая и легко вынимается/извлекается для ремонта. 10. На атомоходах пар производится энергией, выделяемой при распаде радиоактивного топлива. 6 Did you know? The engines of some of the world’s biggest container ships weigh 2,300 tons! Their propellers alone weigh 130 tons. They’re so powerful and complicated that they require over a dozen people PLUS a computer system to operate! That really puts the $200 million price tag of the world’s largest ships into perspective, doesn’t it? 7 UNIT II DIESEL ENGINE OPERATION AND MAIN COMPONENTS РАБОТА ДИЗЕЛЬНОГО ДВИГАТЕЛЯ И ЕГО ЧАСТИ Vocabulary internal combustion engine turbine to drive to spray to ignite to compress to draw in charge stroke suction stroke exhaust stroke compression combustion expansion heat volume scavenging two-stroke engine four-stroke engine to force to force out to drop to occur to require to increase to decrease to transmit to cast stationary parts moving parts bedplate двигатель внутреннего сгорания турбина приводить в движение впрыскивать зажигать сжимать втягивать, всасывать порция, загрузка, заряд ход, такт, длина хода ход впуска (всасывание) ход выхлопа сжатие сгорание расширение тепло объем продувка двухтактный двигатель четырехтактный двигатель заставлять, принуждать вытеснять, выкачивать падать происходить требовать увеличивать(ся) уменьшать(ся) передавать лить, отливать неподвижные части рабочие части фундаментная плита 8 crankcase piston bearing cylinder cast iron cylinder covers (heads) to ensure alloy liner connecting rod crankshaft flywheel valve inlet valve fuel injection valve (spray valve) exhaust valve (or port) crank forged steel alternator to fasten displacement sump environment картер двигателя поршень подшипник цилиндр чугун крышки цилиндров обеспечивать сплав втулка, гильза шатун коленчатый вал маховик клапан впускной клапан форсунка выхлопной клапан (или окно) мотыль кованая сталь генератор переменного тока прикреплять перемещение, сдвиг поддон окружающая среда Diesels are the most economical heat engines. Invented by Rudolph Diesel in 1892, the Diesel engine is an “internal combustion” engine; that is to say, the fuel is burnt inside the engine cylinders and not externally in a separate boiler. Its power is expressed as brake horsepower (b. h. p). The first marine diesel engine was installed in the Selandia, an oceangoing vessel, in 1912. The principle of operation is as follows,- a charge of pure air is drawn, or pumped, into the engine cylinder and then compressed by the moving piston to a pressure of about 500 lbs per square inch. When air is compressed, it’s temperature rises. Fuel is now sprayed into the engine cylinder, is ignited by the hot air and in burning supplies more heat to the air charge thus causing it to expand and drive the engine piston. 9 There are two main types of diesels: two-stroke and four- stroke engines. Engines of either type may be single-acting or double-acting. As to their construction they may be of trunk-piston type, crosshead type and opposed-piston type. They can also be classified into high speed, medium speed, slow speed engines. In two-stroke diesels compression occurs during the first stroke, combustion and expansion occur during the second stroke; exhaust, scavenging and recharging with air occur at the end of the second stroke and at the beginning of the first stroke. The working cycle of a four-stroke diesel requires four separate strokes of the engine piston to complete the operation. These four strokes are called suction, compression, combustion-expansion and exhaust, but only the third stroke provides the power to drive the ship. So, what happens during these four cycles? First stroke: suction. Inlet valve is open, exhaust valve is closed. Air is drawn into the cylinder. Second stroke: compression. Both valves are closed. Piston compresses the air to high temperature. Third stroke: combustion-expansion. Fuel injected burns. Temperature and pressure of combustion gases increase. Gas pressure forces the piston down (valves are closed). As the volume available for the gases increases, their pressure and temperature decrease. Piston displacement is used to produce power. Fourth stroke: exhaust. Exhaust valve is open, inlet valve is closed. Burnt gases are forced out of the engine. The Diesel Engine is made up of stationary and moving parts. Stationary parts. These are principally: Bedplate and crankcase. These two parts make a supporting structure to hold the cylinders, crankshaft and main bearings in firm relation to each other. Crankcase also serves as sump for the lubricating oil. Cylinders. They are stationary walls of the combustion chamber, they serve also to guide the pistons to which the mechanical energy 10 created by combustion is transmitted. The ordinary engine is made of cast iron and heavy-duty engines are made of steel alloys or aluminum alloys. In the multi-cylinder engine, the cylinders are cast in one block known as cylinder block. Cylinder covers (heads) close the top end of the cylinders over which inlet and exhaust valve are mounted. Cylinder liners. As the cylinders have to ensure smooth movement of the piston rings, their walls are covered with a material that has good friction resistance qualities, such as a special cast iron or alloy. This covering is sometimes removable, which means it can be replaced at low cost when it becomes worn. It is called a liner. Moving parts. These include: piston, connecting-rod, crankshaft, flywheel and valves. Piston. It is made of steel, cast iron or special alloy which is highly resistant to heat stresses. According to size, the piston is provided with piston rings. Piston transfers the strain resulting from the pressure to the connecting rod. Рис.1 11 Connecting rod. The connecting rod transmits force from the piston to the crank on the crankshaft. The special steel alloys or aluminum alloys are used for the manufacture of connecting rod. Valves serve to admit the air and to discharge the exhaust gases. Crankshaft. It is made of forged steel. It receives the sum of the mechanical energy produced in the cylinders and transfers it to the parts that use it: the propeller, the alternator, etc. Flywheel is a heavy wheel fastened to the crankshaft. Its purpose is to keep the engine running smoothly from the time of one power stroke to the next power stroke. Diesels have a universal record of reliability in marine environment, they are long-lived and easier to maintain. EXERCISES Ex.1. Answer the questions. 1. What are the main types of marine engines? 2. What is the Diesel engine? 3. Where and when was the first Diesel engine installed? 4. How is the Diesel engine power expressed? 5. What is the principle of operation of the Diesel engine? 6. How many strokes are necessary to complete the operation? 7. What are the strokes of the four-cycle Diesel engine? 8. What happens during each stroke? 9. What stationary parts does the Diesel engine consist of? 10. What are the moving parts of the Diesel engine? 11. What’s the function of a cylinder? 12. What material is used to make the engine parts? Ex.2. Give Russian equivalents. air charge, gas pressure, piston displacement, combustion gases, heat stresses, closed chamber, controlled movement, sprayed fuel, expanded gases, compressed air, increased volume, mechanical work, burnt gases, to produce power, to drive a ship, to transmit the energy, to hold crankshaft and cylinders in firm relation, to run smoothly, removable covering, moving parts, stationary parts, cylinder block. 12 Ex.3. Make up sentences of your own using the following verbs. To compress; to inject; to force out; to increase, to produce, to transmit, to cast. Model: To draw. Air is drawn into the combustion chamber. Ex.4. Put the proper English equivalents instead of Russian words. 1. The diesel engine (состоит) of the following parts: (фундаментной плиты двигателя и картера). 2. The crankcase (сделан) of steel. 3. (Крышки цилиндра) close (верхнюю часть) of the cylinders. 4. (Втулка) is a comparatively thin cylinder. 5. Piston (сжимает воздух) to high temperature. 6. The connecting rod (соединяет) the piston to the crank on (коленчатом вале). 7. (Коленчатый вал) transmits the mechanical energy (на винт). 8. Temperature and pressure of (газов сгорания) increase. Ex.5. Translate. 1. Двигатель - это любая машина, которая потребляет тепловую энергию и превращает ее в механическую работу. 2. Дизель является двигателем внутреннего сгорания. 3. Топливо сгорает внутри цилиндров двигателя. 4. Когда воздух сжимается, его температура поднимается. 5. В двухтактном двигателе сгорание и расширение происходят во время второго такта. 6. Энергия образующаяся во время третьего такта поршня обеспечивает движение судна. 7. Дизельный двигатель состоит из неподвижных и подвижных частей. 8. Дизели долговечны и легки в эксплуатации. Ex.6. Give a short description of the working process of. a) the first stroke; b) the second stroke; c) the third stroke; d) the fourth stroke. 13 Ex.7. The answers are given. What are the questions? 1. ______________________? It is expressed in bhp. 2. _______________________? During the 3rd stroke. 3. _______________________? They close the top end of the cylinders. 4. _______________________? It’s a connecting rod. 5. ________________________? It is made of forged steel. Ex.8. Choose the right term to the following definitions. Cylinder cover, crankshaft, piston, bedplate, cylinder liner, connecting rod, piston rings, turbocharger, flywheel, inlet valves 1. It is a key component of an engine transmitting cylinder power to the propeller shaft. 2. This part converts the force of expanding gases during combustion process to mechanical energy. 3. It increases the overall power and efficiency of an engine. 4. This part of the engine represents a thin metal cylinder inserted on top of a cylinder block and secured at the top by cylinder head. It also provides area for cooling, lubrication and scavenging. 5. It works as a foundation block for the two-stroke marine diesel engines. It is strong and flexible to support weight and handle fluctuating forces produced by the engine. 6. They prevent the combustion gases leak or escape from the space in between cylinder head and piston crown. They are made up of cast iron alloys with added minerals like molybdenum, chromium, titanium and nickel. 7. Its main function is to form the top part of the combustion space; while supporting all necessary valves required for the operation such as inlet, exhaust and fuel injector. They are exposed to 14 maximum temperature and pressure so provided with adequate cooling arrangement. 8. This part does the function of transforming the reciprocating motion of a piston into rotary motion of crankshaft. It also does the work of transferring power produced by the piston to the crankshaft. 9. Their function is to inject a charge of fresh air in the combustion space. 10. It is a mechanical device specifically designed to efficiently store rotational energy (kinetic energy). Ex.9. Study the basic engine performance parameters and be ready to discuss and remember them. An important parameter for a marine diesel engine is the rating figure, usually stated as BHP (or kW) per cylinder at a given rev/min. The basic engine performance parameters are: Indicated Power: The amount of power developed by the combustion of the fuel in the cylinder. Fuel Energy: The actual amount of energy stored in the Fuel = Mass of the fuel × Calorific value of the fuel. Indicated Thermal Efficiency: This is the ratio between the Indicated power to the Fuel Energy is called. Mechanical Efficiency: The mechanical efficiency is defined as the ratio of the power output to the power developed in the cylinder. Volumetric Efficiency: Volumetric efficiency is nothing but the breathing ability of the engine. And this is one of the important performance parameters for the four stroke engines. Volumetric efficiency is defined as the amount of air intake to the rate at which the volume is displaced by the system. Mean Effective Pressure: The average pressure inside the cylinders of the internal combustion engine based on the resulted power output. Mean Piston Speed Specific Power Output: The specific Power output can be simply defined as the power output per unit area of the piston. 15 Specific Fuel Consumption: It is an important parameter in terms of determining the performance of the Engine. It is defined as the ratio of the fuel consumed per unit time to the power output generated. Calorific Value (CV) of the Fuel: The calorific value of the fuel is defined as the amount of thermal energy released per unit quantity of fuel when it is burned completely. Air-Fuel Ratio: The proportions of the air with the fuel play a crucial role in the performance of the engine. This is expressed in the terms of air-fuel ratio. In diesel engines where the fuel is entered separately with the help of the fuel injectors, so that if the load need to be increased, then the fuel amount will be increased directly in the cylinder. Ex.10. Be ready to speak on Diesel engines. 16 UNIT III TYPES OF MARINE DIESELS ТИПЫ ДИЗЕЛЬНЫХ ДВИГАТЕЛЕЙ TEXT 1 A 4-STROKE ENGINE ЧЕТЫРЕХТАКТНЫЙ ДИЗЕЛЬНЫЙ ДВИГАТЕЛЬ Vocabulary internal combustion engine двигатель внутреннего сгорания stroke ход, такт revolution оборот single – acting простого действия double – acting двойного действия to require требовать to complete = to make делать,совершать suction (intake) всасывание to draw in втягивать, всасывать inlet valve впускной клапан cam кулачок upward stroke ход (поршня) вверх downward stroke ход (поршня) вниз to compress сжимать compression сжатие clearance volume рабочий объем цилиндра lb. per sq. in – pounds per square фунтов на кв.дюйм to reach достигать fuel injection valve форсунка finely atomized мелко распыленный to spray впрыскивать combustion space = combustion камера сгорания chamber to ignite воспламеняться heat тепло, нагревать to expand расширяться power stroke рабочий ход 17 exhaust valve to escape to drop (fall) combustion products except expansion ignition (firing) T.D.C. B.D.C. выпускной клапан уходить, исчезать падать продукты сгорания за исключением расширение воспламенение верхняя мертвая точка нижняя мертвая точка Any internal combustion engine has a four-stroke cycle or a twostroke cycle. The four-stroke engine requires four piston strokes to convert fuel into work. The movement of the piston from the top to the bottom of its cylinder is known as a stroke. While the piston moves up and down the cylinder two times, the crankshaft revolves twice. The strokes are commonly known as suction, compression, power (combustion-expansion) and exhaust. 1. Suction stroke. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). As the piston moves down on its suction stroke, a charge of pure air containing the necessary oxygen for combustion is drawn in through the inlet valve in the cylinder head. 2. Compression stroke. This stroke begins at B.D.C or just at the end of the suction stroke, and ends at T.D.C After the piston has completed the suction stroke, the inlet valve closes, and the piston starts on an upward stroke, called compression stroke, compressing the charge of pure air into the clearance volume to a pressure of between 350 and 450 lb. per sq. in. 3. Combustion (Power). This is the start of the second revolution of the four stroke cycle. About the time that the piston reaches the end of its upward stroke, the fuel injection valve opens for a short period, and finely atomized fuel oil is sprayed in the combustion space under high pressure. Because of the heat compression, the fuel oil is ignited and burns generating heat. The piston has now started downward on its third stroke, and the hot gases generated by the combustion of the oil expand and force the piston downward on its working or power 18 stroke. This stroke produces mechanical work from the engine to turn the crankshaft. 4. Exhaust. Near the end of the working stroke the exhaust valve in the cylinder head opens, part of the gases escape, and the pressure in the cylinder drops approximately to the atmospheric. The piston now returns from B.D.C. to T.D.C. while the exhaust valve is open, and all the products of combustion are forced out through the open exhaust valve. The exhaust valve now closes, and the cycle is renewed. EXERCISES Ex1. Give Russian equivalents to the following. to convert fuel into work, single acting engine, from the top to the bottom, the crankshaft revolves twice, a charge of pure air, containing oxygen for combustion, previous stroke, about the time, open for a short period, because of, generating heat, generated by the combustion of the oil, to force the piston down, to turn the crankshaft, approximately to the atmospheric, are forced out through the valve, the cycle is renewed. Ex.2. Find English equivalents to the following Russian words and word combinations. 4 - (2) - тактный двигатель, каждый оборот коленчатого вала, такты всасывания, сжатия, горения и расширения, выхлоп, ход поршня вверх (вниз), давление и температура, падать, атмосферное давление, камера сгорания, впрыскиваться, форсунка, повторяется, продукты сгорания, выталкивать через открытый выпускной клапан. Ex.3. Match the opposites. 1. rise 2. draw in 3. top 4. upward 5.complete 6. exhaust valve 7. single 8. generate 1. use 2. outside 3. inlet valve 4. force out 5. next 6. drop 7. downward 8. bottom 19 9. previous 10.inside 9. start 10.double Ex.4. Point out the suffixes in the following words, translate them into Russian and use in sentences of your own. 1. compression, combustion, expansion, revolution, injection, formation; 2. expanded, injected, renewed, increased, atomized, generated; 3. removable, measurable, suitable, considerable, reliable, possible; 4. stability, safety, ability, activity, reality, viscosity; 5. greatly, easily, carefully, clearly, extremely, directly. Ex.5. Answer the following questions. 1. What types of diesel engines can you name? 2. What is a piston stroke? 3. How many strokes of the piston are necessary to complete the cycle in the 4 cycle engine? What are they? 4. What valves must be closed during compression stroke? Why? 5. How do the expanded gases act? 6. Does the piston start its upward or downward movement during the compression stroke? 7. When and how is fuel sprayed into the combustion chamber? 8. What takes place when the exhaust valve opens? 9. What happens after the exhaust valve closes? Ex.6. Describe the 4-stroke internal combustion engine and all the processes occurring in it. Did you know? How and where is ship’s engine made? If you have seen engines on ships, including small 4 stroke generator engines and also the massive 2 stroke propulsion engines, one thought which must have crossed your mind is how and where these engines were made? The most famous engine manufacturers, whose engines, are used in ships are: 1. MAN Diesel & Turbo (Previously B&W engines) – famous for high, medium and slow speed marine engines. 20 2. 3. 4. 5. 6. Wärtsilä (previously Sulzer Engines) – famous for high, medium and slow speed marine engines. Mitsubishi – producing engines for light, medium, and heavy-duty applications. Rolls-Royce – famous for the cruise ship and naval ship engines. Caterpillar manufactures – for medium speed and high-speed marine diesel engines. Wärtsilä is still the Guinness World Record holder for the largest ship engine ever built. The Wärtsilä RT-flex96C two-stroke engine fitted with turbocharger holds this record. Manufactured for large container ships, its dimensions are as follows: Length - 27 meters (88 ft 7 in), Height - 13.5 meters (44 ft 4 in) Weight > 2,300 tones. Power output ~ 84.42 Megawatts (114,800 bhp). The size of the ship engine varies from ship to ship, type of stroke it has, and its power output. The ship engine can be as high as a 5-story building, and to accommodate it, the ship engine room has to be designed accordingly. TEXT 2 A 2 STROKE ENGINE ДВУХТАКТНЫЙ ДИЗЕЛЬНЫЙ ДВИГАТЕЛЬ Vocabulary scavenging scavenging air receiver recharging to complete to occur to comprise sequence of events to substitute to arrange exhaust manifold продувка ресивер продувочного воздуха перезарядка, перезагрузка завершать происходить охватывать, включать порядок действий заменять устанавливать выхлопной коллектор 21 to store slightly simultaneously to cover to uncover port to rush in remainder to incline tangentially whirling motion disadvantage while still partially below to increase increase trunk type crosshead type stuffing box splash up хранить (ся) немного, слегка одновременно прикрывать, закрывать открывать окно врываться остаток отклонять тангенциально вихревое движение недостаток в то время как, пока все еще частично; здесь: немного ниже увеличить, поднять увеличение, подъем тронковый тип крейцкопфный тип муфта брызгать, разбрызгивать Two-stroke (or two-cycle) engine is a type of internal combustion engine which completes a power cycle with two strokes (up and down movements) of the piston during only one crankshaft revolution. This is in contrast to a “four-stroke engine“, which requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust (or scavenging) functions occurring at the same time. In a two-stroke engine power is produced in one revolution of the crankshaft (360° rotation) whereas in case of four-stroke engine power is produced in two revolutions of the crankshaft (720° rotation). There are two cycles in two-stroke engines. The 1st stroke (upstroke) comprises suction- compression and the 2nd stroke (down stroke) comprises combustion-exhaust. 22 Scavenging and recharging with air occur during the latter part of the down stroke and the beginning of the next succeeding upstroke. This sequence of events is made possible by substituting ports in the bottom of the cylinder wall for one or more exhaust valves. There are two groups of these ports, one for the exhaust and the other for scavenging air, usually on opposite sides of the cylinder, but in some designs both groups are arranged on the same side. The exhaust ports connect with the exhaust manifold, while the scavenging ports communicate with the scavenging air receiver. The exhaust ports are slightly higher than the scavenging ports, so that they are uncovered by the piston while the scavenging ports are still closed. This is necessary because the cylinder gas is at a pressure of about 40 lb. per sq. in when exhaust begins, and, if the scavenging ports were open, the exhaust gas would blow into the scavenging air receiver. During the short time before the piston uncovers the scavenging ports, the gas pressure falls to atmosphere with the result that when the scavenging ports are uncovered, scavenging air rushes into the cylinder and blows the remainder of the burned gas out. The scavenging ports are inclined upward to direct the air toward the top of the cylinder and usually are positioned tangentially to give the air whirling motion. A two-stroke diesel, however, is less thermally efficient than a four-stroke and fuel consumption is higher. The life of a two-stroke diesel tends to be shorter than that of a four-stroke model because of the higher loads placed on the engine. What's more two-stroke diesels tend to be far noisier in operation than four-stroke engines. Crosshead and Trunk differences. There are two variants of a two-stroke diesel engine: the trunk type or the crosshead type. Trunk engines have a shorter stroke than a crosshead and have the piston connected to the crankshaft by a simple connecting rod. They will use a common lubricating oil for all aspects of the engine and the oil will splash up to lubricate the liner. Trunk two-strokes are rarely used these days as prime movers. Crosshead engines have much longer strokes and in these engines, a diaphragm plate separates the crankcase from the cylinder liner space and the piston has a long rod passing through the plate using a stuffing box that separates the upper cylinder lubricant from the system oil. The 23 piston rod is connected at the crosshead to the connecting rod attached to the crankshaft. These are the engines that power the vast majority of bulk carriers, container ships and general cargo vessels. There are also a significant number of LNG carriers that have two-stroke diesel engines. EXERCISES Ex.1. Translate into Russian. To complete a power cycle, compression occurs, upstroke (down stroke) of the piston, during the latter part of the down stroke, up and down movements to be made possible by substituting opposite sides of the cylinder, in some designs, on the same side, less thermally efficient, low pressure scavenging air receiver, the gas pressure falls to the atmosphere, to be slightly higher, to be uncovered by the piston, to be still closed, toward the top of the cylinder, with the result that, to be inclined upward, to direct, to be positioned tangentially, to be thermally efficient, fuel consumption, crosshead diesel engine. Ex.2. Give opposites to the following words. Down stroke, intake, to disconnect, bottom, to cover, upper, to blow in, advantage, partially, below, to increase, to start, usual, high, necessary, fall, long,, upward, before, vast, efficient. Ex.3. Form nouns from the following verbs and translate them into Russian. to rotate ___________ to operate ___________ to substitute ___________ to scavenge ___________ to start ___________ to compress ___________ to move ___________ to transform ___________ to revolve ___________ to locate ___________ to construct ___________ to connect ___________ 24 to measure ___________ to increase ___________ to communicate ___________ to exhaust ___________ to recharge ___________ to complete ___________ Ex.4. Study and read the following noun chains, translate them into Russian and use in sentences of your own. Note: NOUN CHAIN (Цепочка существительных) – это вид словосочетания, представляющий собой ряд трех или более существительных, определяющих одно понятие. В таких словосочетаниях главное существительное, выполняющее непосредственно функцию существительного, стоит всегда в конце цепочки, а все предшествующие слова, связанные с ним, являются определениями. В начале словосочетания, как правило, стоит артикль или другой определитель. Noun + Noun + Noun + Noun Example a power plant a ship power plant a ship power plant operation a ship power plant operation survey a ship power plant operation survey issues ( problems) four-stroke diesel engine; diesel engine power output; low-speed diesel engines; compression stroke beginning; combustion gases temperature; scavenging air receiver; removable piston covering; combustion-expansion stroke; upward piston movement; heat stresses problem; piston rings smooth movement. Ex.5. Translate into English using your active vocabulary. 1. Движение поршня от верхней мертвой точки до нижней мертвой точки называется ходом поршня. 2. Цикл четырехтактного дизельного двигателя состоит из впуска, сжатия, сгорания-расширения и выхлопа. 25 3. 4. 5. 6. 7. 8. Рабочий процесс двухтактного двигателя совершается за 2 хода поршня: хода поршня вверх и вниз. Во время тактов впуска и сгорания поршень перемещается вниз, а во время тактов сжатия и выпуска он перемещается вверх. В двухтактном двигателе мощность вырабатывается за один оборот коленчатого вала, в четырехтактном двигателе мощность генерируется за два оборота коленчатого вала. В двухтактном дизеле продувочные окна сообщаются с ресивером продувочного воздуха, а выпускные окна с выхлопным коллектором. Двухтактные двигатели тронкового типа редко применятся сегодня в качестве главных двигателей. Этот тип двигателя широко применяется на контейнеровозах, балкерах и универсальных судах. Ex.6. Make up questions to cover the main contents of the text. Ex.7. Study the following information, be ready to make a comparative analysis of two types of diesels in Russian. 2-STROKE ENGINE 1. It has one revolution of crankshaft within one power stroke. 2. Power is produced once during 2 strokes of the piston. 3. A 2-stroke engine has ports which makes its design simpler. 4-STROKE ENGINE 1. It has two revolutions of crankshaft between one power strokes. 2. Power is produced once every 4 strokes of the piston. 3. A 4-stroke engine design is a bit complicated due to valve mechanism. 4. 2-stroke engines require 4. A 4-stroke engine requires lighter flywheel compare to other heavy flywheel because it engines because it generates generates unbalance force due to more balanced force due to one two revolutions for one power revolution for one power stroke. stroke. 26 5. In 2-stroke engine charge is 5. In 4-stroke engine charge is partially burnt and mix with the fully burnt and does not mix with burnt gases during inlet. It is due burnt charge in ideal condition. to port mechanism. 6. More lubricating oil requires 6. Comparatively, less because some oil burns with fuel. lubricating oil requires. 7. 2-stroke engines give less 7. 4-stroke engines give more thermal efficiency. thermal efficiency. 8. 2-stroke engines are less effi- 8. 4-stroke engines are more cient and generate more smoke. efficient and generate less smoke. 9. 2-stroke engines are compara- 9. 4-stroke engines are expensive tively cheaper. due to valve and lubrication mechanism. 10. 2-stroke engines create more 10. 4-stroke engines are less noise. noisy. 11. 2-stroke engines are easy to 11. 4-stroke engines are manufacture. comparatively hard to manufacture. 12. In 2-stroke engines due to 12. In 4-stroke engines less wear poor lubrication more wear and and tear occurs. tear occurs. Ex.8. Act the dialogues. Dialogue A - Что Вы знаете о типах дизельных двигателей? - Существуют четырехтактные и двухтактные двигатели. - Что касается принципов действия, каковы они? - Простого действия и двойного действия. - А что насчет конструкции? - Двигатели бывают крейцкопфными, тронковыми и с противоположно движущимися поршнями. Dialogue B - Во время такта сжатия все клапаны должны быть закрыты, не так ли? - Какие клапаны вы имеете в виду? 27 - Воздушный впускной клапан, форсунку и выпускной клапан. Да, естественно. Иначе не будет сжатия. Каковы давление и температура сжатия? Около 500 фунтов и около 1000 градусов по Фаренгейту, то есть около 100 кг/кв.см и 500 градусов по Цельсию. Топливо впрыскивается под давлением, не так ли? Да, оно довольно высокое, 3550 фунтов на квадратный дюйм. Во время горения температура газов растет? Да, до 3000 градусов по Фаренгейту, то есть около 1500 градусов по Цельсию. В конце такта (хода) расширения давление газов падает до примерно 40 фунтов и они начинают выходить, не так ли? Да, так. Таким образом, мы теперь видим полный цикл работы. Ex.9. Describe the 2-stroke internal combustion engine and all the processes occurring in it. Ex.10. Diesel engine Quiz. Check yourself. 1. When was the diesel engine invented? a) 1878 b) 1892 c) numa1902 2. The diesel engine was invented by… a) scientists working for the German corporation Die Siel Weltwirtschafts. b) Rudolph Diesel c) Otto von Diesel 3. What inspired Rudolf Diesel to invent a new kind of engine? a) family b) some global problems c) efficiency 4. What's the first step in a diesel engine's combustion process? a) fuel mixing b) air compression c) fuel injection 28 5. In some diesel engines both exhaust and intake processes happen on the same piston stroke. These engines are known as ... a) 2-stroke engines b) 4-stroke engines c) non-conforming engines 6. What ignites the diesel to create the 'bang' or 'power' stroke? a) heat from friction b) hot compressed air c) spark plugs 7. The inlet valve and the exhaust valve at the top of the cylinder open and close during the 4-stroke cycle. During the power stroke are they ... a) both open b) both closed c) exhaust open and inlet closed 8. Why does the engine need air? a) for combustion, cooling the engine compartment and for dispersing any noxious fumes b) to allow the engineers to breathe in the engine room c) to stop the engine corroding 9. After an engine oil/filter change why is it necessary to run the engine? a) to check if the engine runs smoothly b) to check for oil leaks, and to allow the oil to be distributed around the engine equally c) to make sure it starts 10. What's biodiesel made from? a) recycled plastics b) petroleum c) plant oils and fats Did you know? SMART engines ABC’s medium speed engines are designed to be SMART. SMART stands for Simple, Mechanical, Affordable, Reliable and Tailor-made. They are user-friendly and deliver outstanding performance under 29 the toughest and most demanding conditions. ABC (Anglo Belgian Corporation) engines are characterized by low fuel and lube oil consumption, resulting in an exceptionally low lifecycle cost. Each engine is customized to the specific requirements of the customer. 30 UNIT IV DIESEL ENGINE COOLING SYSTEM СИСТЕМА ОХЛАЖДЕНИЯ ДИЗЕЛЬНОГО ДВИГАТЕЛЯ Vocabulary damage properties crack to dispose of burning fuel combustion chamber for convenience put to uses scavenging air lubricating oil exhaust manifold crosshead guides point of application fresh water cooling medium circuit cylinder jacket thermostat exhaust valve cage exhaust manifold jacket storage tank the simplest arrangement enclosed leakage scale sediment eliminate ущерб свойства трещина избавляться, ликвидировать горящее топливо камера сгорания для удобства применять, использовать продувочный воздух смазочное масло коллектор отработавших газов, выхлопной коллектор направляющие крейцкопфа точка приложения; возможности применения (здесь) пресная вода охлаждающая среда контур (здесь) рубашка цилиндра термостат корпус выпускного клапана рубашка выхлопного коллектора расходный танк (цистерна); сборный танк (цистерна) простейшее устройство замкнутый утечка накипь осадок, отложения исключать 31 A diesel engine works on the principle of internal combustion of fuel oil. The pistons of the engine are driven by the controlled explosion of the fuel-air mixture, and corresponding rapid increase in pressure inside the cylinders. A marine diesel engine is designed for non-stop operation. From the time the ship departs from a port until it reaches another port, the main engine has to run. This could last several months. The heat from the combustion of fuel have to be taken away continuously otherwise the metal components will become damaged. The material properties of the engine parts can change when it reaches high temperatures. Thermal stress can occur leading to cracks, deformation and weaknesses in the material. Continuous cooling of the engine is necessary. The temperatures have to be maintained at an optimum level. They must not be too hot or too cold. The principle function of the cooling system is to dispose of heat transferred to the metal surfaces adjacent to the combustion chamber. It's also used to cool scavenging air, lubricating oil, exhaust gases, crosshead guides, fresh water, oil and scavenging air. All these points of application may be included in a single system. There are three main cooling systems: enclosed fresh water system, seawater cooling system and oil-cooling system. The most often used cooling system is an enclosed fresh water system. In this case seawater is used for cooling fresh water, oil and scavenging air. An enclosed cooling system means that there is a small tank on the top of the engine that uses a combination of fresh water and coolant. This fresh water is circulated through the engine and through a heat exchanger. The fresh water, in this system, absorbs the heat of the engine. The water that enters the bottom of each cylinder jacket flows upward, passes into the cylinder head, then through the exhaust valve cage and into a pipe leading to the exhaust gas manifold jacket and then it is led to the thermostat. The latter delivers part of the water to the cooler and the rest of it to the circulating pump to be recirculated. In case the temperature of the cooling water rises, the thermostat directs greater part of the water to the cooler and lesser part is to be recirculated. 32 All-salt water method is the simplest arrangement, as it results in fewer pumps and eliminates water coolers and storage tanks. The use of fresh water method reduces troubles due to scale, sediment and corrosion. Oil-cooling method is used for cooling pistons, which eliminates troubles due to leakage of water into the lubricating oil, but causes smaller temperature difference between the inner and outer walls of the piston. In some cases the pistons are cooled with fresh water. Seawater is used for cooling the coolers, through which the fresh water and oil are passed after leaving the engine. EXERCISES Ex.1. Read, translate and remember. cooling system, principal function, to dispose of heat, burning fuel, combustion chamber, scavenging air, lubricating oil, exhaust manifold, crosshead guides, points of application, single system, fresh water, cooling medium, enclosed fresh water system, cylinder jacket, cylinder head, exhaust valve cage, exhaust jacket, temperature rise, circulating pump, salt-water method, simplest arrangement, storage tanks, to reduce the troubles, inner walls, outer piston walls. Ex.2. Answer the following questions. 1. What is the cooling system designed to do? 2. Which parts of the diesel engine require cooling ? 3. Why is cooling necessary ? 4. How many types of cooling systems can be found on board? 5. Why is salt water cooling method considered to be the simplest arrangement? 6. Why do we not use seawater for direct cooling? 7. What method eliminates troubles due to sediment, scale and corrosion? 8. What does an enclosed cooling system mean? 9. What is the main advantage of the central cooling system? 10. When is oil-cooling method applied? 33 Ex.3.Match the opposites and translate them into Russian. 1. heater 1. fresh water 2. impossible 2. below 3. to reduce 3. different 4. equal 4. complex 5. salt water 5. possible 6. over 6. to exceed 7. efficiency 7. below 8. simple 8. cooler Ex.4. Read, study and translate. VERB STUDY TO PROVIDE (снабжать, обеспечивать, предоставлять) 1. Thermostatic valves are provided to regulate the flow of either the fresh water or the seawater. 2. To reduce the corrosive action and inhibit the formation of scale deposits in the system is usual to provide some form of water treatment. 3. In order to compensate for air which may become dissolved in the water and released when heated, an open tank is provided at the height above the highest point of the system. The verb “to provide” may be equivalent to the following verbs: to fit, to mount, to build in, to install, to supply, e.g.: 1. There are thermostatic valves to regulate the flow of either the sea or the fresh water. 2. Thermostatic valves are fitted (supplied, mounted, placed, installed, built in) to regulate the flow of either the fresh or the seawater. Ex.5. Rearrange these sentences using the verb “provide”. Make all necessary changes. Mind Passive model. Example: There are doors on the cylinder casing, through which the water spaces may be cleaned and inspected when overhauling the engine. Doors are provided on the cylinder casing, through which the water spaces may be cleaned and inspected when overhauling the engine. 34 1. 2. 3. 4. 5. 6. These manufacturers supply the piston rings which can be run in quickly. Modern medium-speed engines are turbocharged. There is a control bore in the cylinder cover to enable possible gas leakage to be detected between the two parts of the cover. The new maintenance system ensures higher reliability and lower costs. On most engines sea water and fresh water pumps are fitted. In the cylinder head there is an indicator for measuring the cylinder pressure. Did you know? Overcooling causes just as much damage to an engine as overheating. Overcooling most commonly occurs when the coolant bypasses a defective water temperature regulator and flows directly to the radiator preventing the engine from reaching normal operating temperature. 35 UNIT V DIESEL ENGINE LUBRICATION SYSTEM СМАЗОЧНАЯ СИСТЕМА ДИЗЕЛЬНОГО ДВИГАТЕЛЯ Vocabulary to ensure to maintain film tight seal wear surface to remove lubricating oil failure stop gear service tank drain tank splash lubrication drilling groove store circulatory branch sump crankpin wristpin crosshead bearing scraper rings black oil обеспечить поддерживать пленка герметичное уплотнение износ поверхность удалить, снять стоп редуктор смазочного масла расходный резервуар сливной бак смазка разбрызгиванием (погружением) отверстие паз хранить(ся) циркулирующий ответвление поддон (картера) палец кривошипа цапфа крейцкопфный подшипник маслосъемные кольца мазут Lubrication is essential for any kind of machinery onboard ships. Its main function is to ensure the formation of an oil film between the moving parts to reduce friction and wear and thus prolong their service life. The lubricating oil is also used to create gas tight seal between the piston rings and cylinder wall, to keep surfaces clean and to remove heat. Lubricating system comprises lubricating oil cooler, lubricating oil filter, lubricating oil pumps and drives, lubricating oil failure stop gear, cylinder lubricating oil service tank and lubricating oil drain tank. 36 The oil is used for the lubrication of most vital engine components: cylinders and bearings. Cylinder lubrication Its principal purpose is to maintain a film of oil between the piston rings and the liner and also so that any acid produced by combustion of the fuel is neutralized by the oil and does not cause corrosion. Some of this lubrication will be supplied by so called "splash lubrication" which is the oil splashed up into the liner by the rotating crankshaft. However, larger medium speed marine diesel engines also use separate pumps to supply oil under pressure to the cylinder liner. The oil is led through drillings onto the liner surface where grooves distribute it circumferentially around the liner, and the piston rings spread it up and down the surface of the liner. In 4-stroke engines there are different ways for lubricating the cylinder liners, depending on the size and type of the engine: –– splash from the revolving crankshaft –– inner lubrication where the oil is supplied from the piston side In 4-stroke engines, the lubricating oil is the same as the system oil used for example in bearing lubrication. Most of 2-stroke crosshead engines are fitted with an independent system just for cylinder and piston lubrication. These systems use separate oil pumps to supply pressurized oil to the liner. The cylinder oil is stored in tanks and transferred daily to a small capacity tank by gravity from which it will pass to the cylinder lubrication system. Bearing lubrication Bearing lubrication is effected by means of a circulatory system through which a large amount of oil under pressure is forced through the bearings. In general, the system is made up of a sump or reservoir, from which a circulating pump draws the oil and discharges it through the coolers and filters to a manifold which has a branch to each main bearing. Some oil flows out of the ends of the main bearings, while the rest of it passes through an axial hole in the crankshaft to the crankpin bearings. Here more oil is lost out of the end of the bearings and the rest passes up through axial holes in the connecting rods to the wristpin or crosshead bearings. From here all the oil may be discharged from the bearings into the crankpin or a portion may be passed through pipes to 37 the interior of the pistons and thence to the crankpin or sump. From the crankpin or sump the oil returns to the pump for recirculation. In large engines the cylinders are usually separated from the crankcase in such a way that no black oil and none of the crankcase oil can be carried up into the cylinders and burned. In smaller engines, with the lower ends of the cylinders opening into the crankcase, scraper rings in the piston or the liner must be used to prevent these things from happening. Lube Oil System Monitoring Typically, the pressures and temperatures of the fluids in the lubrication system will be monitored and displayed on the engine control panel. A few other items in the lube oil system may also be monitored, as follows: 1. Crankcase pressure (vacuum). Because the oil is contained in the crankcase of the engine, monitoring that space may indicate a problem in the engine. 2. Main bearings may also be monitored for temperature. EXERCISES Ex.1. Form verbs from the following words and translate them into Russian. lubrication, cooler, motion, circulation, opening, provision, connection, heater, production, monitoring, rotation, moving, combustion, indicator, mixture, blower, leakage, arrangement, attendance, repetition, passage, resistance, production, atomization, maintenance. Ex.2. Give opposites to the following. down, cooler, individual, inconvenient, inside, separately, increase, high-speed Ex.3. Translate the following sentences into Russian, paying attention to the Absolute Participial construction. NOTE: Absolute Participial Construction выполняет в предложении функцию сложного обстоятельства и как правило переводится придаточным предложением того типа, которому соответ38 ствует определенное обстоятельство. Это может быть придаточное предложение времени (с союзами – когда, после того как), причины (с союзами – так как, поскольку), условия (с союзом если).Она также может переводиться и самостоятельным предложением с союзами: и, а, в то время как, причем. 1. In the case of oil cooling the lubricating oil is used, a common arrangement being to provide a passage way in the center of the pin. 2. The working pistons are lubricated by forced-feed mechanical lubricators, the oil being injected when the pistons are at the bottom of their travel. 3. In large engines the journal bearings, crankpins, cross-heads, and camshaft bearings are lubricated by the main lubricating oil supply, the oil being circulated under pressure from the sump by a motor-driven lubricating oil pump. 4. In some designs the cooling water is passed from the jacket space in the cylinder head through cored passages in the heavy top flange of the cylinder, a hole being located between each pair of cylinder studs. 5. When cylinders and frames are cast separately the frames may be placed in the same planes as the center through the cylinders, each frame straddling a crank, or located so that each one straddles a main bearing the cranks being located between adjacent frames. 6. In the case of the two-cycle engine the air-inlet and exhaust valves are eliminated, and their place is taken by the scavenging and exhaust ports, with the piston acting as a valve to control the opening and closing of these ports. 7. In the two-cycle engine compression occurs on the first upstroke, combustion and expansion occur during the down stroke, with exhaust, scavenging and recharging with air occurring during the latter part of the down stroke and the beginning of the next succeeding upstroke. Ex.4. Answer the following questions. 1. What is the main function of lubrication? 2. What else is lubricant used for? 3. 3. What arrangements does the engine lubricating system comprise? 39 4. 5. 6. 7. 8. What are the main lubricating points inside the engine ? What is the purpose of cylinder lubrication? How are cylinder liners usually lubricated? How does bearing lubrication system work? What parameters should you pay attention to when monitoring the lubrication oil system? Ex.5. Translate the following sentences into English. 1. Смазочное масло используется для создания герметичного уплотнения между поршневыми кольцами и стенкой цилиндра. 2. Процесс смазки двигателя необходим для снижения трения между движущимися частями и удаления тепла. 3. Существуют различные способы смазки частей двигателя внутреннего сгорания. 4. Масло, используемое для смазки цилиндров должно применяться в небольшом количестве. 5. Масляная циркуляционная система служит для смазки подшипников. 6. Наиболее совершенной является смазка под давлением. 7. За состоянием смазочной системы можно следить на панели управления двигателем. Ex.6. State what equipment is used to: –– control and measure the oil pressure –– control and measure the oil temperature –– keep oil clean –– provide the oil supply to the system Did you know? Cylinder lubrication is particularly difficult due to the high temperatures encountered. This problem is more difficult in twostroke engines than in four-stroke engines as, in the former, there is no nonworking stroke during which it is easier to form an oil film on the cylinder walls. Pressure-charged two-stroke engines are the most difficult of all to lubricate satisfactorily. The problem is aggravated in engines operating on residual fuel due to the high sulphur content increasing corrosive wear. 40 UNIT VI CONVERSATIONAL TOPICS РАЗГОВОРНЫЕ ТЕМЫ 1. MY SPECIALTY МОЯ СПЕЦИАЛЬНОСТЬ Vocabulary aim ship mechanical faculty to provide with to solve field training field to include industrial training special attention to devote (to) fuel system cooling system lubricating system engine arrangement ship-board training to last to keep watch to repair damage junior students senior students undergraduates graduates graduation paper to comprise workshop at one's disposal auxiliary mechanism цель судомеханический факультет обеспечить решать область, отрасль направление подготовки включать производственная практика особое внимание уделять топливная система система охлаждения система смазки устройство двигателя плавательская практика длиться стоять на вахте ремонтировать повреждение студенты младших курсов студенты старших курсов студенты последнего курса выпускники диплом включать в себя мастерская в чём-то распоряжении вспомогательный механизм 41 to obtain skills enterprise experience получать мастерство, навыки предприятие опыт The principal aim of the ship mechanical faculty is to train certificated specialists in the following fields: 1) Shipbuilding 2) Ship power plants 3) Technical maintenance of ship and ship equipment 4) Maintenance of ship power plants Our specialty is maintenance of ship power plants. Students of the conventional training field "Maintenance of ship power plants" study 5,5 years and get a diploma of a specialist. Three other fields train bachelors. The graduates of the faculty get the specialty of a mechanical engineer. The educational course includes both technical and social sciences. Junior students study higher mathematics, physics, chemistry, descriptive geometry, strength of materials. Students also have the humanities: history of Russia, philosophy, foreign languages, etc. Senior students study many special subjects such as theory of ship arrangement, details of machines, theory of machines and mechanisms, ship internal combustion engines and others. Special attention is paid to studying fuel system, cooling and lubricating systems. Students study engine arrangement and types of engines. Besides, they study turbine arrangement, boilers and pumps. Students write term-papers on internal combustion engine, propulsion machinery, auxiliary mechanisms and devices. To acquire professional skills and sea-going experience students of our specialty have different types of training at the end of each year. The total duration of practical training within a course of education shall be one year. Students have industrial training at different plants and enterprises, shipboard training on river and sea ships. Students keep watch, do work as motormen, help to repair damages of an engine, study ship's documents and make entries into the engine log-book. 42 The ship mechanical faculty comprises several chairs: such as ship internal combustion engines chair, ship building chair, ship repairing chair, technology of metals chair and others. There are some mechanical workshops, labs of internal combustion engines, labs of auxiliary mechanisms, a metal-cutting lab at the disposal of students. Theoretical training during the educational process is necessarily supported by a unique simulator training. After successful completion of training, graduates of our specialty together with a diploma of higher education, receive a package of documents with which they have the opportunity to find job in almost any shipping company in the world. Answer the following questions: 1. What University do you study at? 2. What's the name of your faculty? 3. What's the aim of teaching at the faculty? 4. What subjects do junior and senior students study? 5. What specialty do the graduates from the ship mechanical faculty get? 6. What special subjects are the students taught? 7. Why is special attention devoted to studying cooling, fuel, lubricating systems? 8. What kind of training do the students of the faculty have? 9. Where do the students of the faculty have practical training? 10. What do the students do during this training? 11. What chairs does your faculty comprise? 12. What makes a graduate of your specialty unique? Did you know? Personal requirements for marine engineers. Marine engineers need to be: –– responsible –– practical, methodical and adaptable –– accurate, with an eye for detail –– excellent problem-solvers –– confident decision-makers who remain calm in emergencies –– good communicators –– good at math and physics. 43 Marine chief engineer duties. Marine chief engineers are responsible for the entire technical operations of the vessel including engineering, electrical, and mechanical divisions. They are the head of the entire engine department aboard the ship. They have overall responsibility for all technical operations and equipment on-board the ship. Marine chief engineers collaborate on security, survival and health care on board, observe the national and international standards of application. 2. TURBINES ТУРБИНЫ Vocabulary turbine steam turbine gas turbine impulse turbine impulse-reaction turbine single-cylinder turbine compound turbine tandem-compound turbine cross-compound condensing turbine 2-casing unit low pressure turbine intermediate pressure turbine high pressure turbine axial turbine radial turbine H.P. turbine L.P. turbine constant-pressure turbine constant-volume turbine device arrangement турбина паровая турбина газовая турбина активная турбина активно- реактивная турбина однокорпусная турбина составная турбина одновальная турбина двух-вальная турбина конденсационная турбина двух-корпусный агрегат турбина низкого давления турбина среднего давления турбина высокого давления осевая турбина радиальная турбина турбина высокого давления турбина низкого давления турбина с постоянным давлением сгорания турбина с постоянным объёмом сгорания механизм, устройство приспособление, устройство 44 converting steam jet heat engine rotor moving blades casing to revolve stationary nozzles to expand gland bearing shaft throttle valve governor pressure drop to impinge to cause rotation to constitute drive to increase to decrease diaphragm successive stage cast iron cast integral plate steel cast steel to weld nozzle orifice corrosion-resisting alloy alloy cross-section solid section partition преобразование паровая струя тепловой двигатель ротор движущиеся рабочие лопатки корпус вращаться направляющие сопла расширяться уплотнение подшипник вал дроссельный клапан регулятор перепад давления ударяться вызывать вращение составлять привод увеличивать уменьшать перегородка последовательная ступень чугун цельнолитой толстолистовая сталь литая сталь сваривать сопло отверстие коррозийно-стойкий сплав сплав поперечное сечение сплошная секция перегородка 45 convergent divergent steel forging solid forging built-up rotor journal groove gland strip blading gas turbine power plant compressor combustion chamber intercooler re-heater axial-flow turbo compressor radial-flow or centrifugal compressor positive displacement compressor overall thermal efficiency to withstand peculiarities to accommodate thermal expansion velocity ahead turbine astern turbine суживающийся расширяющийся стальная поковка цельнокованый составной ротор шейка вала паз уплотнительное кольцо комплект лопаток газотурбинная силовая установка компрессор камера сгорания промежуточный охладитель нагреватель аксиально-проточный турбокомпрессор радиальный или центробежный компрессор поршневой компрессор общий тепловой КПД выдерживать особенности учитывать (здесь) тепловое расширение скорость турбина переднего хода турбина заднего хода The turbine is a heat engine consisting of a rotor carrying moving blades, a casing in which the rotor revolves, and stationary nozzles through which the steam is expanded or directed. Glands, bearings, throttle valve, governor and other devices are necessary for operation of the unit. There are two kinds of turbines: steam turbines and gas turbines. The steam turbine consists of two principal elements: 46 1) nozzles, a device for converting some thermal energy of the steam into kinetic energy 2) moving blades, an arrangement for converting the kinetic energy of the steam into shaft work. Steam turbines may be classified as impulse turbines and reaction turbines. In the impulse turbine the steam expands only through stationary nozzles, dropping in pressure and increasing in velocity. The steam then impinges against the moving blades causing rotation and mechanical work. In the reaction turbine the stationary nozzles have the same appearance as the moving blades. The steam drops in pressure and at the same time expands while passing through both the stationary nozzles and the moving blades. Turbines are classed also as: 1) high 2) intermediate 3) low pressure There may be single-cylinder and compound turbines. Singlecylinder indicates that the unit consists of one turbine contained in one casing. A compound unit consists of two or more individual turbines. Compound turbines are further classified as 1) tandem-compound 2) cross-compound In the tandem- compound unit all the individual turbines are mounted upon a common shaft. In the cross- compound unit each turbine has a separate shaft. According to the direction of steam flow the turbines are axial-flow and radial-flow. They may be condensing and non-condensing as well. The condensing turbine exhausts their steam to a condenser which maintains back pressure, while the noncondensing unit usually exhausts its steam to another device where it is used for heating. Gas turbines work on exactly the same thermodynamic cycle as an ordinary Diesel engine: they draw in air from the atmosphere, compress 47 it, heat the compressed air by the direct burning of fuel in it and then make the air perform work. The units which make up a complete gas turbine power plant are: the compressor, combustion chamber, intercooler, re-heater, gas turbine itself. The installation includes an electric motor, which serves to start the turbine and the computer. EXERCISES Ex.1. Suggest English equivalents for the following and memorize them. тепловой двигатель, движущиеся лопатки, ротор, корпус, неподвижные сопла, подшипник, дроссельный клапан, уплотнение, регулятор, механизм, установка, активная турбина, реактивная турбина, паровая турбина, газовая турбина, преобразование тепловой энергии пара в кинетическую энергию, преобразование кинетической энергии пара в работу вала, расширяться, падение давления, увеличение скорости, ударяться о лопатки, вращение, однокорпусная турбина, составная турбина, одновальная и двухвальная турбина, осевая турбина, радиальная турбина, конденсатор, сжатый воздух, газотурбинная силовая установка, компрессор, камера сгорания, промежуточный охладитель, нагреватель, электродвигатель. Ex.2. Answer the questions. 1. What is a steam turbine? 2. What are the principle elements of a steam turbine? 3. What function do they perform? 4. What basic types of steam turbines do you know? 5. What is the difference between an impulse turbine and a reaction one? 6. Can you speak on classification of turbines as to the a) pressure, b) steam flow? 7. What units does the gas turbine power plant consists of? 8. What cycle does it work on? 48 Ex.3. Choose the right definition to the terms in the scheme. 1. 2. 3. 4. 5. 6. 7. 8. A part of a turbine carrying moving blades A device through which the steam is expanded or directed An arrangement for converting the kinetic energy of the steam into shaft work. A turbine consisting of two or more individual turbines. Each turbine has a separate shaft inside this unit. Steam expands only through stationary nozzles in this type of steam turbines. This type of turbine exhausts their steam to a condenser. They work on exactly the same thermodynamic cycle as an ordinary Diesel engine. Ex.4. Translate the following sentences into English. 1. Паровые турбины служат для превращения тепловой энергии пара в механическую работу. 2. В соплах потенциальная энергия пара преобразуется в кинетическую. 3. Пар поступает в сопла, где расширяется. 49 4. 5. 6. 7. Во время этого расширения пар приобретает значительную скорость. В активных турбинах расширение пара происходит только в соплах. В реактивных турбинах пар расширяется как на неподвижных, так и рабочих лопатках. Простейшая газотурбинная установка состоит из компрессора, камеры сгорания, промежуточного охладителя, нагревателя и турбины. Ex.5. Act the dialogues. 1. 2. –– Do you know where the steam expands in impulse turbine? –– Yes, I do. In the stationary nozzles. –– And what about pressure and velocity? –– The pressure decreases and velocity increases. I’ve seen it in the diagram. –– Is there any expansion in the moving blades? –– No, never. There is no expansion there, only in the nozzles. In the moving blades the pressure is constant. –– I see. I have to remember it. –– Can you explain the difference, between the impulse and reaction turbine? –– Yes, sure. The main difference is in construction. Let me show it to you on the figure. –– I see only the blades here. Stationary and moving ones. –– Right you are, and both act as nozzles. That means that there are two expansions. –– Let us see them on the diagram. –– The lines show that the pressure drops in every step and velocity pulses. –– Thanks a lot. 50 3. –– What’s the propulsion of your ship? –– A set of cross- compound turbines. –– What type of gear is used there? –– It’s a double- reduction year. –– What S.H.P. do the turbines develop? –– 26.500 at 109 rpm. –– I think steam conditions are high, aren’t they? –– Rather. 590 lb/in2 505°C. –– I see. Thank you. Ex.6. Complete the dialogues. 1. A - ..................................................................................................... ? B - Rotor, casing, moving blades and stationary nozzles. A - ..................................................................................................... ? B - In nozzles. A - ..................................................................................................... ? B - The kinetic energy of the steam is converted into shaft work. 2. A - What are the main types of steam turbines? B - ...................................................................... . A - Do you know what’s the difference between them? B - Sure, ........................................................................ . 3. A - ........................................................................................................ ..............? B - They work on the same thermodynamic cycle as an ordinary Diesel engine. A - Can you tell me about other units of a gas turbine power plant? B - I think, I don’t remember them all, but I’ll try. .................................... ................................................................................................................ . Ex.6. Get ready to speak on turbines. 51 UNIT VII TEXTS FOR READING, TRANSLATING AND RENDERING ТЕКСТЫ ДЛЯ ЧТЕНИЯ,ПЕРЕВОДА И АННОТИРОВАНИЯ И РЕФЕРИРОВАНИЯ ПРАКТИЧЕСКИЕ РЕКОМЕНДАЦИИ ПО НАПИСАНИЮ АННОТАЦИЙ И РЕФЕРАТОВ Аннотирование и реферирование являются важнейшими формами обработки источников информации и отличаются друг от друга прежде всего глубиной и степенью полноты отражения информации, а также и средством обучения иностранному языку в техническом вузе. АННОТИРОВАНИЕ - подготовительная база для обучения реферированию. Целесообразно начинать обучение именно с аннотирования. При аннотировании происходит восприятие отдельных слов, словосочетаний, фрагментов предложений или отрывков текстов, обобщение разрозненных сведений в одно целое и фиксирование обобщенной информации в форме краткой справки об аннотируемом произведении; т.е. сущность аннотирования состоит в том, чтобы понять в общих чертах содержание произведения, обобщить 2-3 основных положения и оформить полученные сведения в краткую справку об этом произведении - аннотацию (5-8 предложений). Процесс аннотирования включает ряд последовательных этапов работы: 1. Просмотровое чтение всего текста с целью получения общего представления о содержании аннотируемой работы; 2. Просмотр графических изображений и таблиц с целью уточнения понятого при чтении; 3. Выделение основных положений; 4. Обобщение полученных сведений в связный текст; 5. Фиксирование обобщённой информации в форме аннотации. К написанию аннотации предъявляются определённые требования, из которых наиболее характерным является лаконичность. Однако, в текст аннотации целесообразно вставлять дополнитель52 ные слова, например «подробно излагается», «кратко рассматривается», «проблема решена путём», «особое внимание уделено», «автор приходит к выводу», и т.д. При обучении написанию аннотаций можно проделать следующие упражнения: 1. Краткое изложение основных положений несложной по содержанию статьи или отрывка; 2. Сокращение статьи без искажения её содержания; 3. Составление плана к статье и передача содержания статьи по плану; 4. Деление статьи на смысловые части и их озаглавливание; 5. Ответы на вопросы, предложенные на языке; 6. Суммирование информации рисунков, таблиц. Последовательность изложения материала в аннотации всегда должна быть следующей: 1. Предметная рубрика. В этом пункте называется область или раздел знания, к которому относится аннотируемый источник. 2. Тема. Обычно тема определяется наименованием источника, но может формулироваться и самим референтом. 3. Выходные данные источника. В этой рубрике записывается на иностранном языке автор, заглавие, журнал, издательство, место и время издания. Затем эти данные даются в переводе на русский язык. Эта рубрика позволяет легко найти сам первоисточник. 4. Сжатая характеристика материала. Здесь последовательно перечисляются все затронутые в первоисточнике вопросы, а также излагается основной вывод автора материала по всей теме и по основным её вопросам. 5. Критическая оценка первоисточника. Референт не всегда может дать критическую оценку, но наличие такой рубрики желательно. Обычно референт излагает свою точку зрения на актуальность материала, указывает, на кого рассчитан данный материал, какой круг читателей он может заинтересовать. 53 The plan for rendering the text 1. The title of the article. 2. The author of the article, where and when the article was published. 3. The main idea of the article. Some expressions to Translation be used while rendering the text The article is under the Статья под заголовtitle... ком... The text is headed... Текст озаглавлен... Автор статьи... The author of the article is. The article is written Статья написана... by... It is (was) published опубликована... in... It is (was) printed in... напечатана... The main idea of the Основная мысль статьи... article is... The article is about... Статья о... The article is devoted Статья посвящена... to... В статье рассматриThe article deals вается ... with... Статья рассматриваThe article touches ет... upon ... Цель статьи состоит The purpose of the в том, чтобы сообarticle is to give щить читателю... the reader some information on ... The aim of the article Цель статьи заклюis to provide the reader чается в том, чтобы предоставить читаwith some material телю... (data) on ... 54 4. The contents of the article. Some facts, names, figures. А) Автор пишет, соA) The author общает... writes, states... believes... considers... полагает... считает... explains.. .points out... объясняет.. указывает... обсуждает... discusses... сравнивает... compares... подчеркивает... emphasizes... В) В статье описываB) The article ется... describes... С) Согласно тексту... C) According to the В дальнейшем автор text... сообщает... Further the author Дальше в статье reports (says)... The article goes on to говорится... say that.. D) В заключение... D) In conclusion... Автор приходит к The author comes to the conclusion that... выводу, что... 5. Your opinion of I found the article Я считаю статью the article. interesting, important, интересной, важной, of no value, too hard не представляющей to understand. ценности, слишком трудной для понимания. The problem Проблема (вопрос) (question, issue) is -спорная, актуальdisputable...actual... ная... Вопрос - наThe problem is vital сущный... (urgent, burning)... The article is Статья предназнаaddressed to the чена для широкого general reader. круга читателей. 55 РЕФЕРИРОВАНИЕ - выделение наиболее существенной информации и представление её в виде краткого связного текста с критической оценкой прочитанного. Реферат во многих случаях может заменить сам первоисточник. Основными требованиями, предъявляемыми к реферату, являются: 1. Объективность; 2. Полнота изложения; 3. Единство формы; 4. Объём (2000 печатных знаков независимо от объёма работы). Целесообразно обучать реферированию на материале переведённых статей. Реферат не является сокращённым переводом текста. Позже, с приобретением известных навыков, можно предлагать и непереведенные статьи. Тексты для реферирования должны быть конкретные, интересные по содержанию, с элементами новизны. На начальном этапе рекомендуется делать реферат на русском языке. Рекомендуются следующие виды упражнений при переходе к процессу реферирования: 1. Постановка поисковых задач; 2. Деление текста на смысловые отрезки; 3. Озаглавливание каждого отрывка; 4. Устный перевод отдельных абзацев; 5. Составление перечня проблем, затронутых в тексте; 6. Сокращение сложных предложений; 7. Сокращение (выброс) информации, не относящейся к теме; 8. Прочитать текст и найти ответы на вопросы; 9. Выделить главную идею, суть; 10. Рассказать на русском языке, о чем идет речь; 11. Выделить новизну, ценность, полезность информации. Всякий реферат имеет единую структуру. Синтаксис реферата однообразен. В тексте преобладают простые предложения (неопределённо-личные, безличные). Для связанности изложения используются специфичные выражения, типа: «установили, отмечено, рассматриваются, указывается, вызывает интерес», а также специальные языковые клише: «статья посвящена, автор считает, целью статьи является, первая глава описывает» и т.д. 56 1. 2. 3. 4. 5. 6. 7. Этапы написания реферата: Прежде чем начать реферировать, необходимо прочесть весь материал, досконально понять все нюансы его содержания. Референт приступает к составлению подробного плана всего первоисточника. Весь материал разбивается на разделы, подразделы и пункты.(Часто сам источник имеет такую разбивку). Желательно все пункты такого плана формулировать назывными предложениями, оставляя после каждого пункта свободное место для последующего формулирования главной мысли этого раздела. После составления плана первоисточника референт выделяет главную мысль каждого раздела и важнейшие доказательства, подкрепляющие эту мысль. Они записываются одним-двумя краткими предложениями. Необходимо полностью отвлечься от языка оригинала, выделить главную мысль и суметь кратко сформулировать её. Завершив обработку всех пунктов плана, необходимо сформулировать главную мысль всего первоисточника, если это не сделано самим автором. Составить текст реферата, начав с его формальной части, т.е. с предметной рубрики, темы и выходных данных, после чего записать формулировку главной мысли всего первоисточника и последовательно все формулировки по каждому из пунктов плана. Завершить реферат кратким комментарием по такой схеме: а) актуальность всего материала; б) на кого материал рассчитан. Составив полный текст реферата, его следует весь прочитать и, если необходимо, стилистически отшлифовать, стремясь увязать отдельные пункты реферата в единый связный текст. Text 1. FROM THE STEAM ENGINE TO THE DIESEL Development of the internal combustion engine of which the Diesel constitutes a particular type began in the second half of the 19th century. The first Diesel engine was built in Germany in 1897 under the direction of Rudolf Diesel himself. But it was only after the First World war that this engine truly left the experimental stage thanks to the availability of a mechanical fuel injection system. 57 The first Diesel locomotive appeared in the USA in 1925. Then beginning in the 1930, railcars engines were put into service in Europe. In the USA Diesels began to be put into general use in the form of medium- power locomotives in 1942 during the Second World War. Their use expanded rapidly in the following years. From 1950, introduction of powerful Diesel engines made it possible for Diesel locomotives to equal the performance of the electrically powered engines. First the French Railways were equipped with a high number of Diesel engines, but then the density of the rail network and of rail traffic made electrification the preferable choice and it was only for marine industrial and trucking application that Diesels enjoyed extensive development. Text 2. THE TRANSFORMATION OF POTENTIAL ENERGY INTO MECHANICAL WORK The principle of all engines consists in transforming the potential energy of a fuel into mechanical energy, first it is necessary to produce heat, which is then transformed into work. In almost all current applications, the production of heat is obtained by means of the chemical reaction of oxidation occurring between a hydrocarbon (or other fuel) and an oxidizer which supplies oxygen. The oxidizer is most often air which contains one-fifth oxygen by volume. The products of combustion are: –– Carbon dioxide –– Water, if the fuel burnt contains hydrogen –– A great deal of heat, which raises the temperature of the gases produced, causing them to expand. The reaction always occurs between gases. If the fuel is not in gaseous form, it is necessary to make it gaseous. If after combustion of all the fuel there is oxygen left over, there is, as one says, an excess of air, meaning the fuel was poor in fuel. If on the other hand, there is unburned fuel remaining and no oxygen, the mixture is said to be too rich. The expansion of the gases heated by combustion produces "work" or mechanical energy. 58 Text 3. WHO INVENTED THE DIESEL ENGINE? Not surprisingly, it was German engineer Rudolf Diesel (1858– 1913). Here, briefly, is the story: –– 1861: French engineer Alphonse Beau de Rochas (1815–1893) outlines the basic theory of the four-stroke engine and files a patent for the idea on February 16, 1862, but he fails to put together a working machine. –– 1876: German engineer Nikolaus Otto (1832–1891) builds the first, successful, four-stroke internal combustion engine. –– 1878: Scotsman Dugald Clerk (1854–1932) develops the twostroke engine. –– 1 8 8 0 : A g e d 2 2 , R u d o l f D i e s e l g o e s t o w o r k for refrigerator engineer Carl von Linde (1842–1934), where he learns about thermodynamics (the science of how heat moves) and how engines work. –– 1890: Diesel figures out how to make an improved internal combustion engine using higher pressures and temperatures, which doesn't need a sparking plug. –– 1892: Diesel begins patenting his ideas to prevent others from profiting by them. –– 1893: Diesel builds a huge, stationary engine that works for one entire minute, under its own power, on February 17. –– 1895: Diesel's engine patent is granted in the United States on July 16. –– 1898: With Diesel's help, the first commercial engine is built in a factory in St Louis, Missouri, United States by Adolphus Busch (1839–1913), brewer of Budweiser beer. –– 1899: Manufacture of diesel engines begins at Diesel's plant in Augsburg. Diesel begins licensing his ideas to other firms and soon becomes very wealthy. –– 1903: Petit Pierre, one of the first diesel ships, begins working on the Marne-Rhine canal in France. –– 1912: MS Selandia, the first ocean-going diesel ship, makes its maiden voyage. –– 1913: Diesel dies in mysterious circumstances, apparently falling overboard from the ship Dresden while traveling from 59 London, England to Germany. Rumors circulate that he has been murdered or committed suicide, but nothing is ever proved. –– 1931: Clessie Cummins, founder of the Cummins Engine Co., builds one of the first successful diesel-engine cars and demonstrates its efficiency by driving it from Indianapolis to New York City on just $1.39 of fuel. –– 1931: Caterpillar revolutionizes agriculture by introducing the Diesel Sixty, its first diesel-powered crawler tractor, based on the popular Caterpillar Sixty. –– 1936: Mercedes introduces the 260D, one of the first massproduced diesel-engined passenger cars, and it remains in production until 1940. Over the next four decades, Mercedes sells nearly two million diesel-powered cars. –– 1939: General Motors unveils its EMD FT, a powerful dieselelectric locomotive, and sends the first one (Number 103) on a year-long voyage to demonstrate its worth. Proving beyond doubt the superiority of diesel, this sounds the death knell for steam locomotives. –– 1970s: A global fuel crisis prompts renewed interest in using small, efficient diesel engines in cars. –– 1987: The world-famous Queen Elizabeth 2 (QE2) ship is refitted with nine diesel-electric engines (each the size of a double-decker bus), making it the most powerful diesel-powered merchant ship at that time. –– 2000: Peugeot introduces the world's first particle filters (PF) for diesel engines on its 607 model, claiming a 99 percent reduction in soot emissions. –– 2015: Volkswagen is plunged into a huge global scandal after systematically cheating on diesel engine emissions tests. Diesel car sales plummet for the first time in years. –– 2017: Volvo becomes the first major carmaker to shift away from gasoline and diesel engines, announcing that all new cars will be hybrids or fully electric from 2019. 60 Text 4. RUDOLF DIESEL (1858 - 1913) Rudolf Diesel was born in Paris in 1858. His parents were Bavarian immigrants. Rudolf Diesel was educated at Munich Polytechnic. After graduation, he was employed as a refrigerator engineer. However, his true love lay in engines design. Rudolf Diesel designed many heat engines, including a solar-powered air engine. In 1893, he published a paper describing an engine with combustion within a cylinder, the internal combustion engine. In 1894, he filed for a patent for his new invention. Rudolf Diesel was almost killed by his engine when it exploded. However, his engine was the first that proved that fuel could be ignited without a spark. He operated his first successful engine in 1897. In 1898, Rudolf Diesel was granted patent for an "internal combustion engine" the Diesel engine. The diesel engines of today are refined and improved versions of Rudolf Diesel's original concept. They are often used in submarines, ships, locomotives, and large trucks and in electric generating plants. Rudolf Diesel originally conceived the diesel engine to enable independent craftsmen to compete with large industry. On August 10, 1893 Rudolf Diesel's prime model, a single 10-foot iron cylinder with a flywheel at its base, ran on its own power for the first time. Rudolf Diesel spent two more years making improvements and in 1896 demonstrated another model. By 1898 Rudolf Diesel was a millionaire. His engines were used to power pipelines, electric and water plants, automobiles and trucks, and marine craft, and soon after were used in mines, oil fields, factories, and shipping. Rudolf Diesel obtained patents for his design in Germany and other countries, including the USA. He died at sea after falling from a steamer on the night of Sept. 29/30, 1913. 61 Text 5. DIESEL ENGINE FUEL SYSTEM Service life and reliability of Diesel engines depend to a great extent on their systems. The fuel piping system comprises the fuel supply lines (1), high-pressure fuel lines (2), and fuel heating pipes (3), when heavy fuel is used. Fuel supply lines include the supply lines from the fuel transfer pumps and preheating arrangements to the fuel filters and fuel pumps on the engine; and also fuel supply lines to the installation. High-pressure fuel lines connect the fuel pumps with the fuel valves and are under very high intermittent pressure. Defective high-pressure lines mustn't be repaired by welding not to damage the fuel nozzles by welding beads. Preheating system employs steam up to 7 kg/cm2. Fuel heating pipes are led adjacently along all fuel pressure and supply lines, also filters. Fuel system components and fittings are: settling tanks, day / service tanks, fuel transfer pump, stand-by F.O. pump, fuel oil heaters (if heavy fuel is used), fuel oil filters: coarse and fine strainers of dual flow type (or duplex type), and a number of valves: fuel pressure-maintenance valve, fuel shut-off valve, fuel non-return valve. The function of the fuel transfer pump or the booster is to deliver fuel and to discharge against the counter pressure, adjusted at the pressure-retaining valve. It is driven by an electric motor. Fuel filters are designed for steam heating. There are some filter elements which can be switched over during operation. Fuel pressureretaining valve is designed for adjustable back pressure. The pressure should be high enough to prevent the formation of vapours on the suction side of the fuel pumps. Fuel shut-off valve opens during operation and is provided with a double-cone seat to prevent leakage. Thus, the main pipe can be temporarily isolated for dismantling the fuel pump or preheating. The non-return valve is situated between the fuel pump and the overflow line with single-controlled fuel pumps. During operation the surplus fuel delivered by the fuel transfer pumps runs off into the overflow line. When dismantling a fuel pump, the latter is isolated from the overflow line by the non-return valve. Each cylinder possesses its own fuel pump which discharges a definite quantity of fuel through the discharge line to the fuel valve at the correct moment and under high pressure. The fuel is then sprayed 62 into the combustion chamber in a certain direction through a number of accurate nozzle orifices, and is finely atomized during the process. Text 6. DIESEL ENGINE LUBRICATION SYSTEM The lubrication of moving parts is crucial to diesel engine performance and longevity. The movement of various engine parts under high speed and load conditions creates the requirement for an engine lubrication system. Without some lubricant, friction between parts would quickly wear and generate heat causing severe engine damage and eventually seizure. A number of other lubrication system functions, while not obvious, are critical to good engine operation and durability. Lubrication systems in a diesel engine accomplish the following tasks: 1. Reduce friction between moving parts, which minimizes engine wear, and the creation of heat. 2. Cools a variety of internal engine parts and removes some heat from the engine. 3. Removes dirt, abrasives and contaminants from inside the engine. 4. Assists sealing of the combustion chamber by forming a film between the piston rings and the cylinder wall. 5. Absorbs shock loads between bearings and gears thus, cushioning and protecting engine parts while minimizing engine noise production. 6. Stores an adequate supply of oil for lubricating internal engine parts. 7. Minimizes corrosion of internal engine components How the lubrication system accomplishes some of the above tasks is a function of a number of lubrication system components: –– Engine oil –– Oil pump –– Oil pan –– Oil cooler –– Oil filter(s) –– Pressure regulating and relief valves –– Oil level dipstick 63 Engine oil Of all the components of a lubrication system, engine oil is the most critical given the functions it accomplishes. Lubricating oil is primarily a product of petroleum, commonly called mineral oil. Mineral oils will contain a variety of different hydrocarbon molecules that have different sizes, shapes and lubricating qualities. This means they will perform and respond differently to heat, pressure and other engine operating factors. Today’s oils are a highly refined petroleum product with a package of chemicals called additives to permit lubricating oil to meet engine operational requirements . Text 7. SCAVENGING Efficient scavenging is essential to ensure a sufficient supply of fresh air for combustion. In the four-stroke cycle engine there is an adequate overlap between the air inlet valve opening and the exhaust valve closing. With two-stroke cycle engines this overlap is limited and some slight mixing of exhaust gases and incoming air does occur. A number of different scavenging methods are in use in slowspeed two-stroke engines. In each the fresh air enters as the inlet port is opened by the downward movement of the piston and continues until the port is closed by the upward moving piston. The flow path of the scavenge air is decided by the engine port shape and design and the exhaust arrangements. Three basic systems are in use: the cross flow, the loop and the uniflow. All modern slow-speed diesel engines now use the uniflow scavenging system with a cylinder-head exhaust valve. In cross scavenging the incoming air is directed upwards, pushing the exhaust gases before it. The exhaust gases then travel down and out of the exhaust ports. In loop scavenging the incoming air passes over the piston crown then rises towards the cylinder head. The exhaust gases are forced before the air passing down and out of exhaust ports located just above the inlet ports. With uniflow scavenging the incoming air enters at the lower end of the cylinder and leaves at the top. The outlet at the top of the cylinder may be ports or a large valve. Each of the systems has various advantages and disadvantages. Cross scavenging requires the fitting of a piston skirt to prevent air or exhaust gas escape when the piston is at 64 the top of the stroke. Loop scavenge arrangements have low temperature air and high temperature exhaust gas passing through adjacent ports, causing temperature differential problems for the liner material. Uniflow is the most efficient scavenging system but requires either an opposed piston arrangement or an exhaust valve in the cylinder head. All three systems have the ports angled to swirl the incoming air and direct it in the appropriate path. Text 8. SUPERCHARGING In order to increase the indicated mean effective pressure (m. e. p.) of four-cycle engines and allow them to compete more successfully with two-cycle engines, supercharging has been introduced. Supercharging consists of blowing air under pressure into the cylinder of an engine during the suction stroke and thus having a pressure at the beginning of a compression greater than that of the atmosphere instead of below that of the atmosphere. By increasing the pressure in the cylinder at the beginning of the compression stroke, a greater weight of air is present for combustion — i.e., the volumetric efficiency is increased above unity, and more fuel can be burned per stroke and a higher m. e. p. obtained. The usual practice is to use a supercharging air pressure varying between 2 and 5 lb. per sq. in., which increases the b. h. p between 30 and 40 per cent. At times, increases of 70 per cent in the bhp. have been attained. The value of supercharging is that it allows an increase in m. e. p. without any increase in the maximum temperature during combustion. If the weight of air present in the combustion space is increased 30 per cent, it is possible to inject and burn about 30 per cent more fuel per stroke without any greater rise in temperature during combustion than was the case before supercharging. When supercharging is employed with four-cycle engines, the timing of the inlet and exhaust valves is changed so that they are both open a short time at the beginning of the suction stroke. Thus, when the supercharging air is blown into the cylinder through the inlet valve, it completely scavenges the clearance space. The exhaust valve then closes, and the pressure in the cylinder is greater than that of the atmosphere during the suction stroke. By scavenging the clearance volume and bringing the cylinder pressure up to only atmospheric, the 65 volumetric efficiency of a four-cycle engine is increased from around 87 to around 108 per cent. Since the supercharging raises the i. h. p. of an engine with little increase in the friction horsepower, the mechanical efficiency is increased. When supercharging is employed without any change in clearance volume, the pressure at the end of compression will increase, as will the maximum pressure at the end of combustion. If the clearance volume is increased, it is possible to have the pressure at the end of compression with supercharging the same as without supercharging. This, however, decreases the compression ratio and reduces the temperature at the end of compression. The usual practice is to increase the clearance somewhat and also to allow some increase in the pressure at the end of compression. Air for supercharging is obtained either by an engine-driven blower similar to those used for scavenging two-cycle engines or by a blower driven by an exhaust-gas turbine. Text 9. FUNCTIONS OF AUXILIARY MACHINERY Besides running and maintaining the main propulsion machinery of the ship, the engine officer has a great deal of auxiliary machinery to look after. Auxiliary machinery covers everything mechanical on board ship except the main engines and boilers. It includes almost all t he pipes and fittings and the equipment needed to carry out a number of functions. These functions may be summarized as follows: –– To supply the needs of the main engines and boilers. Air compressors are used to supply compressed air for starting engines. Coolers are used for cooling either oil or water. Water for the boilers is also heated before being admitted in to the boiler by feed water pumps. This increases the efficiency of the boiler. –– To keep the ship dry and trimmed. This is done through the bilge and ballast pumping systems. The former removes water which has gathered in machinery, cargo and other spaces. The latter pumps water into and out of ballast tanks. In general cargo ships, these systems are usually interconnected and served by the same pumps. In tankers and other bulk carriers, 66 these systems are entirely (completely) separate, because these ships may need to ballast at 12,000 tons/hour and therefore need larger pumps. –– To supply domestic needs such as fresh and seawater, sanitation, heating or cooling of air, ventilation. –– To apply the main power of the engines for propulsion and maneuvering. The engine power is transmitted to the propeller by a line of shafting. This is made up of the thrust shaft, intermediate shafts and the propeller shaft. Steering gear is also necessary to operate the rudder for maneuvering. –– To supply the ship with electrical power and lighting. This is done by steam powered generators. –– To moor the ship and handle cargo. Deck machinery is extensive and varied. It can be divided into anchor-handling machinery (windlasses and capstans), mooring machinery (winches and capstans), and cargo-handling machinery (winches and cranes). It also includes cargo oil pumps. –– To provide for safety. Firefighting and fire detection equipment, lifeboat engines and launching gear are also included. –– To prevent oil and sewage pollution. Responsibility for auxiliary machinery is often delegated to individual engineer officers, each one taking responsibility for the efficient working of certain items. A lot of equipment is duplicated, so that for example, one generator can be overhauled without cutting off the supply of electricity to the ship. Engineer officers on tankers are also involved in (busy with) operating the cargo pumping machinery. Text 10. OPERATING PROCEDURES Medium- and slow-speed diesel engines will follow a fairly similar procedure for starting and maneuvering. Where reversing gearboxes or controllable-pitch propellers are used then engine reversing is not necessary. A general procedure is now given for engine operation which details the main points in their correct sequence. Where a manufacturer's instruction book is available this should be consulted and used. 67 1. 2. 3. 4. 5. 6. 7. 8. 9. 1. 2. 3. Preparations for standby Before a large diesel is started it must be warmed through by circulating hot water through the jackets, etc. This will enable the various engine parts to expand in relation to one another. The various supply tanks, filters, valves and drains are all to be checked. The lubricating oil pumps and circulating water pumps are started and all the visible returns should be observed. All control equipment and alarms should be examined for correct operation. The indicator cocks are opened, the turning gear engaged and the engine turned through several complete revolutions. In this way any water which may have collected in the cylinders will be forced out. 6. The fuel oil system is checked and circulated with hot oil. Auxiliary scavenge blowers, if manually operated, should be started. The turning gear is removed and if possible the engine should be turned over on air before closing the indicator cocks. The engine is now available for standby. The length of time involved in these preparations will depend upon the size of the engine. Engine starting The direction handle is positioned ahead or astern. This handle may be built into the telegraph reply lever. The camshaft is thus positioned relative to the crankshaft to operate the various cams for fuel injection, valve operation, etc. The maneuvering handle is moved to 'start'. This will admit compressed air into the cylinders in the correct sequence to turn the engine in the desired direction. A separate air start button may be used. When the engine reaches its firing speed the maneuvering handle is moved to the running position. Fuel is admitted and the combustion process will accelerate the engine and starting air admission will cease. 68 1. 2. 3. 4. 5. Engine reversing When running at maneuvering speeds: Where manually operated auxiliary blowers are fitted they should be started. The fuel supply is shut off and the engine will quickly slow down. The direction handle is positioned astern. Compressed air is admitted to the engine to turn it in the astern direction. When turning astern under the action of compressed air, fuel will be admitted. The combustion process will take over and air admission cease. 6. 7. When running at full speed: 8. The auxiliary blowers, where manually operated, should be started. 9. Fuel is shut off from the engine. 10. Blasts of compressed air may be used to slow the engine down. 11. When the engine is stopped the direction handle is positioned astern. 12. Compressed air is admitted to turn the engine astern and fuel is admitted to accelerate the engine. The compressed air supply will then cease. Text 11. INTEGRATED CONTROL The various control and monitoring systems described so far may be integrated in order to enable more efficient ship operation and reduce manning. Machinery control systems are being combined with navigation and cargo control systems to bring about "Efficient Ship" integrated control systems. Combining previously separate sources of data regarding, for example, ship speed and fuel consumption, enables optimizing of ship or engine operating parameters. An Integrated Control System would be made up of a Bridge System, a Cargo Control System, a Machinery Control System and possibly a Ship Management System. The Bridge System would include an automatic radar plotting aid display, an electronic chart table, an autopilot, a gyro, log, and echo sounder. The Cargo Control System will vary according to the type of vessel, but will enable loading calculations, cargo management, ballast 69 control and data logging. The Machinery Control System will combine various control systems to enable surveillance to UMS requirements, performance and condition monitoring, generator control and automatic data logging. Ship Management would involve administrative record keeping, word processing, stock control and maintenance planning. Workstations with computers, monitors and keyboards would be provided in the appropriate locations, such as the machinery control room, on the bridge, in the cargo control room and various ship's offices. A network would connect the various workstations and enable the exchange of information between them. Inputs from the various monitored items of equipment would be fed to Local Scanner and Control Units (LSCU), which would contain a microprocessor and be effectively a microcomputer. The LSCU is part of a local control loop which can function independently, if necessary. The LSCUs are connected up to a central computer which can interface with them and would act as the workstation for the particular system. Integrating the various systems enables optimal control of a ship and improved efficiency. Fuel consumption figures could be monitored, for example and used to predict an appropriate time to dry dock the vessel as hull resistance increased due to fouling. Condition monitoring of machinery would enable maintenance schedules to be planned in order to minimize breakdowns and repair costs. Satellite communications will also enable data to be relayed from ship to shore for analysis by office-based technical staff. Text 12. INTELLIGENT ENGINES Today the world needs engines that can cope up with the stringent emission norms and higher demands for robust, reliable and smart engines with low operational cost. To achieve the above possibilities, a whole new generation of engine is being developed with a comprehensive use of electronics, hardware and software in large 2 stroke low speed cross head engines known as “Intelligent Engines”. The concept of the intelligent engine revolves around the idea that the engine is thinking for itself. The brain of the system is an electronic control system that analyzes the condition of the engine and the operation of the engine’s system (The fuel injection, exhaust valve, cylinder lube oil and turbo charging system). 70 The intelligent engine concept widens the reliability of traditional engines to facilitate new applications and concepts. The initial cost of such engine is quite high but the operational cost is lower than other engine used with proper operating procedure and trained crew. Basic Concept of Intelligent Engine –– A central electronic control system is incorporated which is the brain of the system and which monitors and evaluate the general condition to keep the operating parameter within limits and maintain the performance of the engine at the higher side. –– Central control system operates Engine control unit (ECU) and cylinder control unit (CCU). –– ECU controls the overall protection and efficient performance of the whole engine. CCU controls the each cylinder of the engine for safe and efficient working. –– This control system saves the engine from damage due to overloading, malfunctioning, maladjustment and lack of maintenance. The intelligent engine provides flexibility in operation by replacing mechanical cam shaft for fuel pump and exhaust valve with common rail system and computer controlled system. To comply with the emission norms, system is incorporated with catalytic clean up system and fuel economy modes which can be selected from bridge. A reversing and crash mode option is provided in the bridge, controlled through the main central electronic control which sends signal to the engine when in operational mode. The central system consists of a program in which the protection system can be overridden in case of emergency. Text 13. MAIN GOALS OF NEW GENERATION MACHINES The basic aim for developing intelligent engine is to reduce the operational cost of the propulsion plant, to have high fluctuation in operation and to cope up with the stringent emission norms imposed by regulating authorities under IMO . Apart from this, the following points to be considered for intelligent engines: 71 I. Reliability of engine increases –– The central monitoring system keeps an eye on the fluctuation of load and distribute equally to all the cylinders. –– It consists of overload protection system which will give alarm and trip’s the engine, ruling out the possibilities of overload and thermal stresses. –– Any other abnormality is displayed with an early warning and alarm system so that the problem can be tackled before it hampers the operational aspects of the engine. –– This system increases the emission control flexibility. II. Fuel and lube oil consumption cost reduces –– The load operating efficiency increases as compared to normal engines which increases the life of the engine and maintenance schedule can be delayed which cut shorts the operational cost. –– The performance is fuel optimized. Fuel oil, lube oil and other lubricants' consumption drastically decreases which reduces the operational cost. –– The engine and its performance is maintained “as new” for its lifetime. –– The cylinder lubrication is one of the most expensive lubrication oil used in marine operation. The consumption is controlled with the help of mechatronic (incorporated with mechanical and electronic controlled enhanced system) cylinder lubrication with advanced dosage of oil. III. Follow up of stringent air pollution emission norms –– Now almost all the countries are following the stringent norms for emission from the ship’s propulsion plant. The intelligent engine gives the flexibility to cope up with different norms for different controlled bodies by enhancing the emission performance characteristics. –– To reduce the emission of harmful substance like NOx and SOx, catalytic controller and fuel control and consumption modes are incorporated in the control system. 72 Text 14. MAINTENANCE SCHEDULE OF MARINE DIESEL ENGINE Engine builders supply detailed instructions on the operation and maintenance of their machinery so that regular maintenance work can be carried out and breakdowns can be kept to a minimum. These instruction manuals are usually kept by the Chief Engineer, but are made available to all members of the engine-room staff. The intervals at which an engine and its parts must be inspected will vary from make to make and will depend on the use the engine has been put to. At frequent intervals, fuel pumps should be examined and adjusted, if necessary. When the engine is running, this will be shown by comparing engine indicator cards and by exhaust temperatures. Pistons should also be examined frequently for cracks. At intervals of six weeks, the fuel valves should be taken out and carefully inspected. Atomizers and filters can be washed with clean diesel fuel oil. Cleaning rags must not be used because they leave behind small pieces of fluff, which may block the holes. Valve seats should be tested and if they are pitted or scratched, the surface should be reground. At intervals of six months piston heads if cooled, must be inspected for deposits of carbon in cooling spaces and cooling pipes. When new piston rings are fitted, care must be taken to ensure there is sufficient clearance to allow for the expansion of the rings. Exhaust valves and manifold must also be examined and excessive carbon deposits removed. All carbon deposits should be removed from cylinder ports. Cylinder liners must be examined externally for deposits of scale. If these deposits cannot be removed by flushing with water, then the liner must be removed for cleaning. The liner should also be measured for wear and renewed, if the limit for wear has been reached. The clearance of connecting-rod top and bottom ends should also be examined and adjusted if necessary. At intervals of one year the maneuvering gear must be examined for wear at the joints of levers and rods. The alignment of the crankshaft should be checked and any incorrect alignment corrected. The main bearings must be examined and readings taken for wear. The clearances of all crankshaft bearings must be maintained at the figure recommended by the makers. Finally, starting air piping and 73 air bottles must be cleaned, and the lubricating oil system thoroughly examined and cleared of deposits. It must be emphasized that the above-mentioned parts are only some items which must be regularly maintained to ensure the efficient working of the machinery. Text 15. EXHAUST EMISSIONS AND CONTROL Marine engine designers in recent years have had to address the challenge of tightening controls on noxious exhaust gas emissions imposed by regional, national and international authorities responding to concern over atmospheric pollution. Exhaust gas emissions from marine diesel engines largely comprise nitrogen, oxygen, carbon dioxide and water vapor, with smaller quantities of carbon monoxide, oxides of sulphur and nitrogen, partially reacted and non-combusted hydrocarbons and particulate material. Nitrogen oxides (NOx) generated thermally from nitrogen and oxygen at high combustion temperatures in the cylinder are of special concern since they are believed to be carcinogenic and contribute to photochemical smog formation over cities and acid rain (and hence excess acidification of the soil). Internal combustion engines primarily generate nitrogen oxide but less than 10 per cent of that oxidizes to nitrogen dioxide the moment it escapes as exhaust gas. Sulphur oxides (SOx) produced by oxidation of the sulphur in the fuel have an unpleasant odor, irritate the mucus membrane and are a major source of acid rain (reacting with water to form sulphurous acid). Acid deposition is a trans-boundary pollution problem: once emitted, SOx can be carried over hundreds of miles in the atmosphere before being deposited in lakes and streams, reducing their alkalinity. Sulphur deposition can also lead to increased sulphate levels in soils, fostering the formation of insoluble aluminum phosphates which can cause a phosphorous deficiency. Groundwater acidification has been observed in many areas of Europe; this can lead to corrosion of drinking water supply systems and health hazards due to dissolved metals in those systems. Forest soils can also become contaminated with higher than normal levels of toxic metals, and historic buildings and monuments damaged. 74 Hydrocarbons (HC) created by the incomplete combustion of fuel and lube oil, and the evaporation of fuel have an unpleasant odor, are partially carcinogenic and smog forming. Carbon monoxide (CO) resulting from incomplete combustion due to a local shortage of air and the dissociation of carbon dioxide is highly toxic but only in high concentrations. Particulate matter (PM) is a complex mixture of inorganic and organic compounds resulting from incomplete combustion, partly unburned lube oil, thermal splitting of HC from the fuel and lube oil, ash in the fuel and lube oil, sulphates and water. More than half of the total particulate mass is soot (inorganic carbonaceous particles), whose visible evidence is smoke. Carbon dioxide: some 6 per cent of the exhaust gas emissions from this engine is carbon dioxide. Although not itself toxic, carbon dioxide contributes to the greenhouse effect (global warming) and hence to changes in the Earth’s atmosphere. The gas is an inevitable product of combustion of all fossil fuels, but emissions from diesel engines thanks to their thermal efficiency are the lowest of all heat engines. A lower fuel consumption translates to reduced carbon dioxide emissions since the amount produced is directly proportional to the volume of fuel used, and therefore to the engine or plant efficiency. As a rough guide, burning one ton of diesel fuel produces approximately three tons of carbon dioxide. International concern over the atmospheric effect of carbon dioxide has stimulated measures and plans to curb the growth of such emissions, and the marine industry must be prepared for future legislation. The scope for improvement by raising the already high efficiency level of modern diesel engines is limited and other routes have to be pursued: operating the engines at a fuel-saving service point; using marine diesel oil or gas oil instead of low sulphur heavy fuel oil; adopting diesel-electric propulsion (the engines can be run continuously at the highest efficiency); or exploiting a diesel combined cycle incorporating a steam turbine. The steam-injected diesel engine is also promising. 75 Text 16. BOILERS Boilers are used on board the ship for producing steam. This steam may be used for driving the main engines, when steam turbines are fitted, or for driving auxiliary machinery such as the windlass. There are two basic types of boilers in use in ships: the fire-tube boiler, and the water-tube boiler. The fire-tube boiler consists of a cylindrical steel shell, which contains a furnace at the bottom. Two or more furnaces may be fitted, depending on the size of the boiler. The furnace is connected to a combustion chamber, situated in the middle part of the boiler. The furnace, the combustion chamber and the tubes are all surrounded by water. Boilers are now mainly used for auxiliary purposes on board ship. Water-tube boilers have replaced fire-tube boilers for generating steam for main engines. They have a steam drum at the top, which is partly filled with water, and water drums at a lower level. These drums are connected by banks of tubes, which also contain water. The furnace is located at the bottom and the whole system is contained in a fire-proof casing. Down comer tubes are placed outside the gas system to act as feeders to the water drums. Gases are heated in the furnace and pass upward, transferring their heat to the water in the tubes. Because the steam drum provides a reservoir of relatively cool water, convection currents are set up causing the water to circulate round the system. Superheaters are added to the system to increase its efficiency. These are located between the rows of tubes. Various valves and gauges are fitted to the boilers. For a water-tube boiler these include the following: safety valves, which are needed to release any excess steam from the boiler; a main stop valve in order to control the passage of steam to the engines; feed valves to add water into the boiler; water level indicators to show the level of water in the boiler; thermometers and pressure gauges for showing the temperature and pressure inside the boiler. In order to be able to drain water from the system drain valves are fitted. Chemical dosing valves are also necessary so that chemicals can be added directly into the boiler. 76 Text 17. DECK MACHINERY Marine deck equipment is very important. Almost every ship needs a crane of some sort for taking provisions and stores aboard in addition tankers need cranes for handling hoses and some dry cargo ships need gear for loading and discharging cargoes. As far as SOLAS goes there are no regulations concerning cranes but their placement will have been taken into account at the design stage and by the class society and all cranes will be marked with a safe working load that should never be exceeded. Crane operation is a skilled task and while most of the time cranes will be operated by crew, there are some ports where local labour will demand the right to operate them under local employment conditions. From a safety point of view, the crew will need to ensure the qualifications of non-crew operatives and ensure that there is some element of supervision at all times. Older vessels may still be equipped with derricks but these are gradually becoming obsolete. Cranes vary enormously in design and operation with the ship usually being fitted with a type that suits the most common cargoes. At one time most of the cranes found on ships were operated by wires for raising and lowering the jib but today it is equally common to see hydraulic rams used instead. Some vessels – particularly those carrying containers or packaged lumber – are fitted with travelling gantry cranes that can run the length of the cargo deck. For heavy lift ships, cranes are designed to work in tandem when handling very heavy loads. On a ship that uses its cranes for several different types of cargo, specialist equipment is likely to be found onboard. As well as hooks and spreaders for lifting general cargo and crates, there may be clamps for lifting newsprint or reels and grabs and buckets for handling cargoes such as grain and coal. Winches A winch is a marine deck equipment device for handling wires or ropes and works by spooling the wire or rope on a drum with a horizontal axis. The winch can be powered by electric or hydraulic motors; steam winches were once common but are now obsolete. Winches on ships are fixed and used for specific purposes. As previously mentioned 77 cargo derricks are now much less common and so the winches needed to provide power for these have also been more or less abandoned. The most common use of a winch is for mooring meaning the winches are mostly located on the fore and after decks at both sides of the ship. Tugs and offshore vessels such as AHTS, seismic survey and OSVs will also be equipped with work winches designed for the very heavy-duty work these ships are used for. The power source for any winch systems can be, as required by the customer, low-pressure hydraulic, high-pressure hydraulic, frequencyconverter electric drive or pole-change electric drive. The choice of drive type often depends on type of application and the actual winch operations. All types have their pros and cons. Windlass Located separately but close to the mooring winches or as an integral part of them, the windlass is the device used for lowering and raising the anchor it does this in tandem with the bow or chain stopper which prevents chain slippage when anchored and when raising the anchor. The anchor chain passes from the anchor and through the hawse pipe, over the windlass and down into the chain locker where the end is secured. The windlass is driven by a motor, either electric or hydraulic, and features a brake and clutch for use in different operations. Anchoring is usually done in one of two ways; letting go or walking back. Before anchoring the anchor, chain must be released from its lashings on the bow stopper. When letting go, the anchor is lowered in controlled steps to a certain depth before being released under gravity. Limiting the height from which it is dropped is essential to stop the chain over running. Walking back means lowering the anchor with gear. The principle difference between walk back and let go methods is that in walk back power is used. Anchoring safely is a skill and the speed and direction of the ship during the process is crucial. Once anchoring is completed the stopper must be closed on the chain to prevent movement. The stopper is in effect a rachet arrangement that prevents the chain from paying out when at anchor and acts as a 78 brake when raising it. This prevents strain on the brake and clutch of the windlass which could burn out in an uncontrolled situation. Text 18. WHAT DOES A SHIP ENGINEER DO? In today's fast paced world, maritime, river and other methods of water transport is done by commercial vessels that need to be technically maintained, repaired and monitored for proper operation. This job requires a deep understanding of technical processes, interaction between various parts of a ship's equipment, but also communication with the ship's crew and its captain. Ships engineers are in charge of crews who maintain and repair technical equipment such as ship engines, pumps, electrical wiring, communication systems and refrigeration equipment. These individuals also have the task of creating comprehensive reports about the ship's current technical status, and requesting any necessary repairs in nearby ports. However, sometimes a ship's technical crew may not have the "luxury" to wait until the vessel reaches a port, and it has to perform emergency repairs on the spot to ensure decent ship operation. Ship engineers also act as liaisons between the ship's command and its captain and technical crews. While people on the deck are usually responsible for navigation, cargo safety, legal issues and communication with port authorities, ship engineers and their crews are responsible for technical operations "below deck." The engine is the heart of a ship. Any malfunction may cause unnecessary delays and even dangerous situations, and it is a ship engineer's task to quickly figure out where the problem resides, make the necessary repairs, report to the captain and make sure anything similar does not happen again during the cruise. When a ship's captain or navigation officers make changes in a ship's speed and direction, its technical crews and their engineers are responsible for making sure that the "technical" aspect of the changes do not affect the overall operation of the maritime vessel. However, ship engineers also respond to emergency situations such as leaks, fires and other dramatic events on board. They conduct and oversee safety operations, emergency drills and check on the readiness of the technical crew to face difficult situations while at sea. Ship engineers 79 work aboard ships, and more exactly, in the compartments where the technical equipment and engines are located. However, ship engineers may also conduct emergency drills and work with the other crew members to make sure they follow technical safety procedures. They work closely with navigation officers and with the ship's captain to ensure proper communication between navigation requirements and the technical potential of a maritime vessel. Text 19. SHIP ENGINEER JOB DUTIES AND TASKS 1. Fabricate engine replacement parts such as valves, stay rods, and bolts, using metalworking machinery. 2. Install engine controls, propeller shafts, and propellers. 3. Maintain and repair engines, electric motors, pumps, winches and other mechanical and electrical equipment, or assist other crew members with maintenance and repair duties. 4. Maintain electrical power, heating, ventilation, refrigeration, water, and sewerage systems. 5. Monitor and test operations of engines and other equipment so that malfunctions and their causes can be identified. 6. Monitor engine, machinery, and equipment indicators when vessels are underway, and report abnormalities to appropriate shipboard staff. 7. Perform general marine vessel maintenance and repair work such as repairing leaks, finishing interiors, refueling, and maintaining decks. 8. Start engines to propel ships, and regulate engines and power transmissions to control speeds of ships, according to directions from captains or bridge computers. 9. Supervise the activities of marine engine technicians engaged in the maintenance and repair of mechanical and electrical marine vessels, and inspect their work to ensure that it is performed properly. 10. Act as a liaison between a ship's captain and shore personnel to ensure that schedules and budgets are maintained and that the ship is operated safely and efficiently. 11. Clean engine parts, and keep engine rooms clean. 12. Maintain complete records of engineering department activities, including machine operations. 13. Monitor the availability, use, and condition of lifesaving equipment 80 and pollution preventatives, in order to ensure that international regulations are followed. 14. Operate and maintain off-loading liquid pumps and valves. 15. Order and receive engine room's stores such as oil and spare parts; maintain inventories and record usage of supplies. 16. Perform and participate in emergency drills as required. 17. Record orders for changes in ship speed and direction, and note gauge readings and test data, such as revolutions per minute and voltage output, in engineering logs and bell books. Text 20. THE WATCHKEEPING SYSTEM The system of watches adopted on board ship is usually a fourhour period of working with eight hours rest for the members of each watch. The three watches in any 12-hour period are usually 12-4, 4-8 and 8-12. The word 'watch' is taken as meaning the time period and also the personnel at work during that period. The watchkeeping arrangements and the makeup of the watch will be decided by the Chief Engineer. Factors to be taken into account in this matter will include the type of ship, the type of machinery and degree of automation, the qualifications and experience of the members of the watch, any special conditions such as weather, ship location, international and local regulations, etc. The engineer officer in charge of the watch is the Chief Engineer's representative and is responsible for the safe and efficient operation and upkeep of all machinery affecting the safety of the ship. Operating the watch An engineer officer in charge, with perhaps a junior engineer assisting and one or more ratings, will form the watch. Each member of the watch should be familiar with his duties and the safety and survival equipment in the machinery space. This would include a knowledge of the fire-fighting equipment with respect to location and operation, being able to distinguish the different alarms and the action required, an understanding of the communications systems and how to summon help and also being aware of the escape routes from the machinery space. At the beginning of the watch the current operational parameters and the condition of all machinery should be verified and also the log 81 readings should correspond with those observed. The engineer officer in charge should note if there are any special orders or instructions relating to the operation of the main machinery or auxiliaries. He should determine what work is in progress and any hazards or limitations this presents. The levels of tanks containing fuel, water, slops, ballast, etc., should be noted and also the level of the various bilges. The operating mode of equipment and available standby equipment should also be noted. At appropriate intervals inspections should be made of the main propulsion plant, auxiliary machinery and steering gear spaces. Any routine adjustments may then be made and malfunctions or breakdowns can be noted, reported and corrected. During these tours of inspection bilge levels should be noted, piping and systems observed for leaks, and local indicating instruments can be observed. Various parameters for the main engine turbo-blowers are also logged. Other auxiliary machinery and equipment, such as heat exchangers, fresh water generator (evaporator), boiler, air conditioning plant and refrigeration plant will also have appropriate readings taken. There will usually be summaries or daily account tables for heavy oil, diesel oil, lubricating oil and fresh water, which will be compiled at noon. Provision is also made for remarks or important events to be noted in the log for each watch. Where situations occur in the machinery space which may affect the speed, maneuverability, power supply or other essentials for the safe operation of the ship, the bridge should be informed as soon as possible. This notification should preferably be given before any changes are made to enable the bridge to take appropriate action. The engineer in charge should notify the Chief Engineer in the event of any serious occurrence or a situation where he is unsure of the action to take. Examples might be, if any machinery suffers severe damage, or a malfunction occurs which may lead to serious damage. However, where immediate action is necessary to ensure safety of the ship, its machinery and crew, it must be taken by the engineer in charge. At the completion of the watch each member should hand over to his relief, ensuring that he is competent to take over and carry out his duties effectively. 82 Text 21. PERIODIC SAFETY ROUTINE In addition to watch keeping and maintenance duties, various safety and emergency equipment must be periodically checked. As an example, the following inspections should take place at least weekly: 1. Emergency generator should be started and run for a reasonable period. Fuel oil, lubricating oil and cooling water supplies and tank levels should be checked. 2. Emergency fire pump should be run and the deck fire main operated for a reasonable period. 3. Carbon dioxide cylinder storage room should be visually examined. The release box door should be opened to test the alarm and check that the machinery-space fans stop. 4. One smoke detector in each circuit should be tested to ensure operation and correct indication on the alarm panel. Aerosol test sprays are available to safely check some types of detector. 5. Fire pushbutton alarms should be tested, by operating a different one during each test. 6. Any machinery space ventilators or skylights should be operated and greased, if necessary, to ensure smooth, rapid closing should this be necessary. 7. Fire extinguishers should be observed in their correct location and checked to ensure they are operable. 8. Fire hoses and nozzles should likewise be observed in their correct places. The nozzles should be tried on the hose coupling. Any defective hose should be replaced. 9. Any emergency batteries, e.g. for lighting or emergency generator starting, should be examined, have the acid specific gravity checked, and be topped up, as required. 10. All lifeboat engines should be run for a reasonable period. Fuel oil and lubricating oil levels should be checked. 11. All valves and equipment operated from the fire control point should be checked for operation, where this is possible. 12. Any watertight doors should be opened and closed by hand and power. The guides should be checked to ensure that they are clear and unobstructed. 83 Text 22. GREEN ENGINE The green engine is one of the most interesting discoveries of the millennium. This engine has got some unique features used for the first time in the making of engines. This engine is a piston less one with features like sequential variable compression ratio, direct air intake, direct fuel injection, multi-fuel usage etc. The efficiency of this engine is high when compared to the contemporary engines and also the exhaust emissions are near zero. The significance of the engine lies in the efficiency when the present world conditions of limited resources of energy are considered. Technical features Compared to conventional piston engine operated on four phases, the Green Engine is an actual six-phase internal combustion engine with much higher expansion ratio. The six phases are INTAKE, COMPRESSION, MIXING, COMBUSTION, POWER AND EXHAUST. The main features of this engine are high air charge rate, satisfactory air-fuel mixing, complete burning, high combustion efficiency and full expansion. The most important characteristic is the expansion ratio being much bigger than the compression ratio. Also, the other main features are the sequential variable compression ratio, constant volume combustion, self-adapting sealing system. Because of these revolutionary inventions the engine has some advantages like the thermal efficiency of the engine is increased. The engine is free of the harmful emissions. As more power is obtained in a less space, the engine is more compact and light. Also, the reciprocating parts are eliminated, so the engine is vibration free. Direct Air Intake Direct air intake means that there is no air inlet pipe, throttle and inlet valves on the air intake system. Air filter is directly connected to the intake port of the engine, therefore highest volumetric efficiency which makes engine produce a high torque of output on all speed range is achieved, and the pump loss which consumes the part of engine power is eliminated. 84 Strong Swirling As a tangential air duck is between combustion chamber and compression chamber, a very strong swirling of air is achieved. Consequently, the air-fuel mixing and the combustion process can have a satisfying working condition. Sequential variable compression ratio This greatly revolutionary innovation can provide the most suitable compression ratio for the engine whatever operation mode it works on with burning variety of fuels. Therefore, an excellent combustion performance is attained. Direct fuel injection Direct fuel injection can provide higher output and torque, while at the same time it also enhances the response for accelerations. Super air-fuel mixing Since the independent air-fuel mixing phase is having enough time for mixing air and fuel under strong swirling and hot situation, the engine is capable to burn any liquid or gas fuels without modifications. An ideal air-fuel mixture could delete CO emission. Also, centrifugal effect came from both strong swirling and rotation of the burner makes the air-fuel mixture denser near the spark plug, it benefits to cold engine starting and managing lean-burning, and allowing the engine use of mass control for output. The lowest surface to volume ratio The shape of combustion chamber is paraboloidal. Thus, the lowest surface-to-volume ratio is obtained, and the engine is having less heat losses and high combustion efficiency. Controllable combustion time Due to the independent combustion phase, compared to the conventional engine which performances lack of efficient combustion time resulting in heavy CO emission and low fuel usage rate, the Green Engine has a sufficient controllable combustion time to match any fuels. Constant volume combustion The fuels can generate more energy while the combustion is occurred on the constant volume. Also, the constant volume combustion 85 technology can allow the engine to have a stable combustion when the lean-burning is managed so the heat losses and NOx emissions are decreased. Multi-power pulses The Green Engine operates on the multi-power pulses with a small volume of working chamber, resulting in compact structure and limited size. Also, a small amount of air-fuel mixtures being ignited on each power pulse can greatly cut down explosion noise. High working temperature Because the burner, which is made by high heat resistance and low expansion rate material, such as ceramic, operates without cooling, and relatively high working temperature can eliminate the quenching zone which is main source of HC emission, and can greatly reduce the heat losses in the combustion chamber. High expansion ratio High expansion ratio can make the burned gases to release much more power, in other words, the waste gases while they run out the engine are only bringing much less energy with them, therefore the engine's thermal efficiency is greatly raised, and at the same time, the noise and temperature of the exhaust are tremendously dropped. Self-adapting sealing system This is another greatly revolutionary innovation applied in the Green Engine; it can eliminate a number of seal plates or strips to achieve gapless seal and to provide most efficient and reliable seal system with less friction. Vibration free As major moving parts, vanes, which are counted in little mass and operated symmetrically, the performance of the engine is very smooth got away from vibration. 86 Text 23. WORKING OF THE GREEN ENGINE The Green Engine has six phases which occur in the following sequence. –– Intake –– Compression –– Mixing –– Combustion –– Power –– Exhaust Intake. The air is admitted directly inside the compression chamber. The air does not undergo any treatment before entry. The air filter is directly connected to the entry of the intake pipe. The amount of the air intake can be varied as per the fuel used. Compression. The air admitted in, then enters into the compression chamber. The compression chamber has variable area. The central disc having arms pushes the air in the compression chamber. The compression chamber is connected to the combustion chamber by a small diameter duct which is tangent to the combustion chamber. So as arm pushes the air in the compression chamber the pressurized air is forced to flow through this duct. As the air flow through it, the air is swirled very fast. The air thus enters the combustion chamber. So as arm pushes the air in the compression chamber the pressurized air is forced to flow through this duct. As the air flow through it, the air is swirled very fast. The air thus enters the combustion chamber. Super mixing. The combustion chamber is also rotating. This centrifugal force from the rotation along with the strong swirling causes the fuel to mix with air. The mixing assures the complete burning of the fuel. The super mixed charge is forced by the arm towards the spark plug. Combustion. The charge is ignited by the spark plug. The combustion time can be varied to burn different grade of fuels. The controlled combustion 87 time gives the complete burning of the charge. The emissions are greatly reduced. Power. The burned products of the combustion are expelled out of the combustion chamber. The high pressure gases push the arm of the compression chamber causing work output. The power is obtained in the form of the power pulses. These pulses reduce the area of the engine. The power pulses also reduce the explosion noise. Exhaust. The burned gases are expelled out. The gases are first expanded in the expansion zone. The expansion ratio is more which ensures the maximum work output. Also, the maximum energy is gained from the gases. The temperature also reduces and hence an optimum utilization of the burned gases is achieved. The burned gases after expansion are pushed into the exhaust pipe and released into the atmosphere. Thus, the six-phase cycle is completed. Text 24. ADVANTAGES AND APPLICATIONS OF THE GREEN ENGINE As obvious from the technical features which include effective innovations, the advantages of the Green engine over the contemporary piston engines are many. Small Size and Light Weight: As Green engine is very compact with multi-power pulses, the size and weight could be 1/5 to 1/10 of the conventional piston engines on same output. Its power to weight ratio could be more than 2 hp per pound without supercharge or turbocharge. Limited Parts: There are only some dozens of parts easy to be manufactured in the engine structure. High Efficiency: Because many great innovations are being employed in the engine design such as: direct air intake, sequential variable compression ratio, super mixing process, constant volume combustion, controllable combustion time, high working temperature of the burner, high expansion ratio and self adapting sealing system etc., the thermal efficiency of the engine could be potentially as high as 65 %, even more if water add-in technology is to be considered. 88 Multi-fuels: Due to six phases of working principle, super air fuel mixing process and constant volume combustion with controllable time, the Green engine becomes the only real multi-fuel engine on our planet; any liquid or gas fuels can be burnt well. Also, it would be ideal to coal powder if special anti-wearing material is employed. Smooth Operation: Due to inherence of good dynamic and static balance the performance of the Green engine is as smooth as an electric motor. Quietness and Low Exhaust Temperature: Burst out under small amount of mixtures, free of vibrations, and high expansion ratio make the Green engine much quieter. It is really environment-friendly. Green engine vehicles could transport troops on the battlefield of the future, and could serve as a vital source of auxiliary power in combat. This is because these engines are quiet, flexible and operate at low temperature. Low Cost: Limited parts, small in size, light in weight and depending upon current mature materials and manufacturing technologies, mean that it would be done at much lower cost on manufacture, transportation, installing to other devices, and maintenance Thus, the Green Engines could be used as the ideal power plants on a very wide range of applications in transportation, communication, farm, mine, engineering, military uses, such as automobiles, aircraft, boats, ships, hovers, tractors, locomotives, generators, snowmobiles, chainsaws, helicopters, tanks, torpedoes, submarines etc. The environmental problems can be effectively overcome by the use of Green engine. It can use almost any type of fuel available. It is superior to the conventional I.C. engine in terms of smooth operation, efficiency and cost. Compared to conventional piston engine operated on four phases, the Green Engine is an actual six-phase internal combustion engine with much higher expansion ratio. Already it is being used in some of the application like aircraft, ships and locomotives. Research is going on for its effective use in wider range of transport vehicles. 89 UNIT VIII TESTS ТЕСТЫ TEST I 1. Перепишите следующие предложения, подчеркните в каждом из них глагол-сказуемое, определите его видовременную форму и залог. 1) The ship is provided with oil residue tanks with the total capacity of 10 cu. m. 2) We have repaired three Russian vessels so far, two from the North Shipping Company and a research vessel belonging to the Academy of Sciences. 3) We were repairing the engine the whole morning and could not leave the port in time. 4) All fuel oil pumps were carefully inspected before bunkering. 2. Перепишите следующие предложения, подчеркните Participle I и Participle II и установите, является ли оно определением, обстоятельством или частью глагола-сказуемого. Переведите предложения на русский язык. 1) The ordered supplies will be delivered tomorrow. 2) When spare parts received, please inform us. 3) According to the ship's specifications, the working pressure of the boiler should be 10 kg / sq. cm. 4) All ships should be equipped with technical facilities that make impossible to discharge water containing oil or oil products into the sea. 3. Перепишите следующие предложения, подчеркните в каждом из них модальный глагол или его эквивалент. Переведите на русский язык. 1) Routine cleaning and overhaul may be carried out at sea. 2) The Chief Engineer can decide which item can run longer than planned. 3) Discharge valves are to be shut and sealed. 4) Pistons should also be examined for cracks. 90 4. Прочитайте и письменно переведите текст, обращая внимание на пояснения к тексту. Fuel System The fuel piping system comprises the fuel supply lines, highpressure fuel lines and fuel heating pipes, if heavy fuel is used. Fuel supply lines include the supply lines from the fuel transfer pumps and preheating arrangement to the fuel filters and fuel pumps on the engine supply also the fuel supply lines to the installation. High-pressure fuel lines connect the fuel pumps with the fuel valves and are under very high intermittent pressure. Fuel system fittings are: fuel transfer pump, fuel filter, fuel pressure -maintenance valve, fuel shut-off valve, fuel non-return valve. The fuel transfer pump is driven separately by an electric motor. The fuel filter contains several filter elements which can be switched over during operation and is designed for steam heating. The fuel pressure-retaining valve is designed for adjustable back pressure. The pressure adjusted should be so high that there is no formation of vapor on the suction side of the pumps. The fuel shut-off valve opens during operations and is provided with a double cone seat to prevent leakage, so that the main pipe can be isolated for dismantling the fuel pumps or preheating. The non-return valve is situated between the fuel pumps and the overflow line with single-controlled fuel pumps. During operation the surplus fuel delivered by the fuel transfer pumps runs off into the overflow line. When dismantling a fuel pump, the letter is isolated from the overflow line by the non-return valve. Each cylinder possesses its own fuel pump, which discharges a definite quantity of fuel through the discharge line to the fuel valve at the correct moments and under high pressure, the fuel is then sprayed into the combustion chamber. Vocabulary 1. fuel piping system - трубопровод топливной системы 2. fuel heating pipes- трубопровод подогрева топлива 3. intermittent pressure - пульсирующее давление 4. pressure-maintenance (remaining) valve - клапан постоянного давления 91 5. shut-off valve - отсечной клапан 6. non-return valve - невозвратный клапан 7. to adjust - регулировать 8. discharge line - трубопровод подачи 9. double cone seat - двухконусное седло 10. overflow line - трубопровод перелива 11. dismantling - демонтаж 12. single-controlled - насос основной TEST II 1. Перепишите следующие предложения, подчеркните в каждом из них глагол-сказуемое, определите его видовременную форму и залог. Переведите предложения на русский язык. 1) The ship is equipped in accordance with the provisions of the International Convention for the Prevention of Pollution from Ships. 2) For generating steam for main engine fire-tube boilers have been replaced by water-tube boilers. 3) The company has refused to make repairs to the damaged boiler on the m/v "Maria Ulyanova". 4) The storm began when the ship was approaching the port. 2. Перепишите следующие предложения, подчеркните Participle I и Participle II и установите, является ли оно определением, обстоятельством или частью глагола-сказуемого. Переведите предложения на русский язык. 1) The ship built in a foreign port is usually repaired at the same yard. 2) The condensing turbines exhaust their steam to a condenser. 3) The auxiliary pump is used when the turbine is started. 4) When received, pistons are carefully checked and measured against their original dimensions. 3. Перепишите следующие предложения, подчеркните в каждом из них модальный глагол или его эквивалент. Переведите на русский язык. 1) This loss, however, can be minimized by careful design. 92 2) The hose is to be connected and disconnected by the shore attendant. 3) Hard particles may also be produced by corrosion. 4) Cylinder liners must be examined externally for deposits of scale. 4. Прочитайте и письменно переведите текст, обращая внимание на пояснения к тексту. Supercharging Supercharging, or pressure charging, is a means of increasing the power output of a given engine. It is the process of filling the engine cylinder with air before the compression stroke starts. The pressure of this air is above atmospheric in order to get a greater weight of air into the cylinder. If to start with a higher pressure, the final compression pressure will be higher. This means that if the engine is supercharged, the volume of the compression space must be enlarged if the compression pressure, will be higher. This means that if the engine is supercharged, the volume of the compression space must be enlarged if the compression pressure is to be kept the same. Having a greater weight of air in the cylinder more fuel is burnt. Although more oil is burnt there is more air present and the ratio of oil to air is the same as without supercharging. Exhaust occurs at a higher pressure, but the temperature of the exhaust is lower than with ordinary operation. The inlet valve opens before the exhaust valve closes and the inlet air being higher in pressure than the exhaust gases at the time the inlet valve opens. The air is blown through the compression space, scavenging out the gases and cooling them, the piston and cylinder walls. This action completely fills the cylinder space with fresh air and the net increase in power developed in the engine may be as much as 50%. In modern Diesel engines exhaust gas turbocharging is widely used. The exhaust-driven turbochargers operate on the pulse system or on the constant-pressure principle, and are independent of the crankshaft. Their speed changes with the load on the engine. The air compressed by the turbochargers flows into the scavenging-air receiver and through nonreturn valve into the chambers below each cylinder. Here it is further 93 compressed by the pistons on their downward stoke before flowing into the combustion space when the pistons uncover the scavenging ports. When the turbocharger is out of action, the ship can run at 75% of her normal speed. Vocabulary 1. supercharging - наддув 2. weight-вес 3. pulse system - импульсная система 4. net increase - чистое увеличение 5. gas turbocharging - газотурбонаддув 6. downward - вниз 7. turbocharger - турбокомпрессор 8. inlet valve - выпускной клапан 9. exhaust valve - выхлопной клапан 10. to occur - происходить 11. scavenging-air receiver - ресивер продувочного воздуха TEST III 1. Перепишите следующие предложения, подчеркните в каждом из них глагол-сказуемое, определите его видовременную форму и залог. 1) The Chief Mate is showing the life-boats to the inspector now. 2) The ice-breaker has already conducted the cargo ship" Gotland" to the port. 3) A lot of oil has been spilled near the coast. 4) When pistons are received by us they are carefully checked and measured against their original dimensions. 2. Перепишите следующие предложения, подчеркните Participle I и Participle II и установите, является ли оно определением, обстоятельством или частью глагола-сказуемого. Переведите предложения на русский язык. 1) The Convention MARPOL 73/78 was primarily aimed at pollution resulting from routine tanker operation. 94 2) MARPOL 73/78 requires unscheduled inspection or mandatory annual surveys of ships. 3) The lubricant employed should be of good quality. 4) A centrifugal pump on the turbine shaft is often used to supply oil. 3. Перепишите следующие предложения, подчеркните в каждом из них модальный глагол или его эквивалент. Переведите на русский язык. 1) Water contamination of lubricating oil on board a ship can seriously damage engine bearings and cause engine failure. 2) The equipment is to be delivered within 12 months. 3) All carbon deposits should be removed from cylinder ports. 4) In turbine design the amount of condenser vacuum must be given due attention. 4. Прочитайте и письменно переведите текст, обращая внимание на пояснения к тексту. Turbocharging In the four-stroke naturally aspirated engine, the air for combustion is drawn in from atmosphere the suction stroke. In the turbocharged engine, the air is supplied pre-compressed and, in some cases, cooled. A greater weight of air for combustion is thus available in the cylinder and due to the valve overlap the cylinder is scavenged of the exhaust gases. The effect of turbocharging is: 1) to increase the weight of air available for combustion; 2) to scavenge the residual gases; 3) to cool all parts in the combustion chamber. With the greater air weight, a greater quantity of fuel can be burned and an increase of power obtained without increasing the temperature and the heat stresses in the engine. The turbocharger comprises a single stage axial flow exhaust gas driven turbine, driving a centrifugal air compressor which draws air from the atmosphere and delivers it under pressure to the air inlet manifold, then through the air inlet valves to the cylinders the gas turbine wheel and air impeller are mounted on a common rotor shaft carried in bearings mounted at each end of the shaft. 95 The impulse energy of the gases from the various cylinders is used to drive the turbocharger and there is no loss of engine power. To ensure efficient scavenging it is necessary to have a large overlap of the air and exhaust valves. With this overlap on multi-cylinder engines it is essential to avoid interference in the exhaust pipes between the exhaust impulses from successive cylinders, as this would interfere with efficient scavenging. To eliminate this, two, three or four exhaust pipes are used depending on the number of cylinders. Vocabulary 1. naturally aspirated engine - обычный двигатель, без наддува 2. residual exhaust gas- остаточный выхлопной газ 3. throttling - дросселирование 4. valve overlap - перекрытие клапанов 5. exhaust gas driven turbine- турбина, приводимая в движение выхлопными газами 6. multi-cylinder engine - многоцилиндровый двигатель 7. to avoid interference - избегать помехи 8. wheel - рабочее колесо, диск 9. weight - вес, объем 10. turbocharger - турбокомпрессор 11. to scavenge - продувать 12. loss - потеря 96 СПИСОК СОКРАЩЕНИЙ, ВСТРЕЧАЮЩИХСЯ В ТЕКСТАХ СУДОМЕХАНИЧЕСКОЙ СПЕЦИАЛЬНОСТИ 1. m - meter - метр 2. ft - foot (30,5 см) - фуг 3. in - inch. (2,5 см) - дюйм 4. mm - millimeter - миллиметр 5. cu.m. - cubic meter - кубический метр 6. yd - yard (91.44 см) - ярд 7. m.l.d - moulded - проектный, расчетный 8. F. - Fahrenheit - температурная шкала Фаренгейта 9. С. - Centigrade - температурная шкала Цельсия 10. dwt. (d.w.) - deadweight - полная грузоподъемность судна, дедвейт 11. Ltd. - limited - (о компании) - с ограниченной ответственностью 12. Nо - number - номер, число 13. о.а. - overall — полный, общий 14. b. p. - between perpendiculars - межу перпендикулярами 15. lb. - libra - pound - фунт 16. atm. - atmosphere - атмосфера 17. eff. - efficiency - производительность, к.п.д. 18. fig. - figure - рисунок 19. etc. - et cetera - и так далее 20. deg. - degree - градус 21. i.e. - that is - то есть 22. е.g. - example- например 23. В.Н.Р. - bhp - brake horse power - мощность 24. I.H.P. - i. h. p - indicated hor­se power - индикаторная мощность 25. E.H.P. - e. h. p. - effective hor­se power - полезная мощность 26. S.H.P. - s. h. p. - shaft horse power - мощность на валу 27. av. eff. - average efficiency - средняя производительность 28. cap. - capacity - мощность 29. pres. - pressure - давление 30. vol. - v. - volume - объем, сила звука 31. v.v. - vice versa - наоборот 32. F.O. - O.F. - fuel oil - жидкое топливо 33. I.P. - intermediate pressure - среднее давление 97 34. p. s. i. - psi - pounds per square inch - фунты на кв.дюйм 35. Lb. per sq. in. - pounds per square inch - фунты на кв.дюйм 36. g.p. - gauge pressure - давление по манометру 37. m.p.h. - miles per hour - мили в час 38. r. p. m. - rev./min - revolutions per minute - обороты в минуту 39. kg/hr - kilograms per hour - кг в час 40. gr/hr/h - grams per horse power per hour - граммы на л.с. в час 41. t/day - tons per day - тонны в день 42. N.C.R. - nominal continuous rating - ном. длительная мощность 43. М.С.Н. - maximum continuous rating - макс. длительная мощность 44. V-type - V-образный 45. c/s - cst – centistokes- сантистокс (ед. вязкости топлива) 46. BDC - bottom dead center - нижняя мертвая точка 47. ТDC - top dead centre - верхняя мертвая точка 48. L.P. - low pressure - низкое давление 49. Н.Р. - high pressure - высокое давление 50. m. e. p. - mean effective pressure - среднее эффективное давление 51. m. i. p. - mean indicated pressure - среднее индикаторное давление 52. L.W.L. - load waterline - грузовая ватерлиния 53. m./v. - motor vessel - теплоход 54. s/s - steamship - пароход 55. naut. - nautical - морской 56. vis., visc. - viscosity - вязкость 57. wt. - weight - вес 58. C.M.R. - continuous maximum rating – продолжительная макс. нагрузка 59. 1/h - 1/hr - liters per hour - литры в час 60. d. c. - direct current - постоянный ток 61. а. с. - alternating current - переменный ток 62. p.c. - percent-процент 63. P (pound) - фунт стерлингов 64. h. p. - horse power - мощность, л.с. 65. lub. - lubrication - смазка 98 66. NTDE - new technology diesel engines - дизели нового поколения 67. TDE - traditional technology diesel engines - традиционные дизели 68. RR - relative risk - относительный риск 69. PM - particulate matter - твердые частицы 70. NG - new technology gasoline - бензин новой технологии 71. LEV - low emission vehicle - автотранспортное средство с пониженным уровнем выбросов 72. IPCS - International Program on Chemical Safety - международная программа по химической безопасности 73. EPA - Environmental Protection Agency - агентство по охране окружающей среды Сокращения, используемые в инструкциях и современных справочниках по диагностике и ремонту дизельных двигателей The list below includes definitions of common acronyms that you may come across; acronyms are alphabetized for your convenience. AAT - Ambient air temperature B5 - Common biodiesel blend; 5% biodiesel, 95% petroleum diesel B10 - Method of approximating diesel engine service life B20 - Common biodiesel blend; 20% biodiesel, 80% petroleum diesel B50 - Method of approximating diesel engine service life CAC - Charge-air-cooler, synonymous with intercooler or after-cooler CEL - Check engine light CDR - Crankcase depression regulator CKP - Crankshaft position sensor CPS - Camshaft position sensor CR - Common rail CTD - Cummins turbo diesel DEF - Diesel exhaust fluid DI - Direct injection DIT - Direct injection turbocharged DOC - Diesel oxidation catalyst DPF - Diesel particulate filter DTC - Diagnostic trouble code 99 EBP - Exhaust back pressure, alternatively EP (exhaust pressure) ECM - Engine control module ECT - Engine coolant temperature ECU - engine control unit EGR - Exhaust gas recirculation EGT - Exhaust gas temperature, typically measured before the turbine inlet of the turbocharger. EOT - Engine oil temperature EP or EBP- Exhaust pressure, exhaust back pressure FSD - Fuel system driver IAT - Intake air temperature, typically used in reference to a sensor in the air intake system IC - Intercooler, synonymous with charge-air-cooler or after-cooler ICP - Injector control pressure, often used in reference to the ICP sensor found on 7.3L and 6.0L Power Stroke diesel engines. The sensor reads the pressure in the high pressure oil circuit IDI - Indirect injection IDM - injector driver module IDS - Integrated diagnostic system IP - Injection pump or injector pump HEUI - Hydraulic electronic unit injector HPOP - High pressure oil pump, referring to the heart of the high pressure oil circuit on 7.3L and 6.0L Power Stroke diesels KOEO - Key on engine off KOER - Key on engine running LP - Lift pump, referring to the low pressure fuel pump on a diesel engine. LSD - Low sulfur diesel MAP - Manifold absolute pressure, the absolute pressure as measured in the intake manifold. Not to be confused with gauge pressure, absolute pressure reads ~14.7 psi at sea level MGP - Manifold gauge pressure, the gauge pressure as measured in the intake manifold. This is synonymous with turbocharger boost pressure. MIL - Malfunction indicator lamp 100 NOx - Nitrous oxides; used as shorthand for the compounds nitric oxide (NO) and nitrogen dioxide (NO2), both of which are an important part of diesel emission regulations. Not to be confused with nitrous oxide. May be used in reference to a NOx sensor, an integral part of SCR emissions systems N-m - Newton meters, a metric measurement of torque (convertible to ft-lbs/lb-ft) OBD - On-board diagnostic system PMD - Pump mounted driver RPM - Revolutions per minute; engine speed SCR - Selective catalytic reduction TFT - Transmission fluid temperature TPS - Throttle position sensor (APPS is more common in diesel applications as there is technically not a traditional "throttle" in most applications) TSB - Technical service bulletin ULSD - Ultra low sulfur diesel VGT - Variable geometry turbocharger WOT - Wide open throttle 101 ГРАММАТИЧЕСКИЕ ТАБЛИЦЫ Active (действительный залог) Future Past Present Indefinite Continuous Perfect am + Ving are have + Ved, V3 has Perfect Continuous have + been + Ving has I have been writing. V, Vs is I write. I am writing. Я пишу (часто). написал (уже, Я пишу (уже час, Я пишу (сейчас). Я только что) с двух) Ved, V2 was + Ving were had + Ved, V3 had + been + Ving I wrote. I was writing. I had written. писал (вчера, Я написал Я в 3 часа, когда (вчера). он вошёл). Я написал (вчера, к 3 часам, до того как...) I had been writing. I have written. will + V will + be + Ving will + have + Ved, V3 I'll write. I'll be writing. I'll have written. Я напишу (завтра). Я буду писать (завтра, в 3 часа). Я напишу (завтра, к 3 часам, до того как он придёт). 102 Я писал (уже 2 часа, когда он пришёл). will + have + been + Ving I'll have been writing. Я буду писать (завтра, к тому времени, когда он придёт). Present Passive (страдательный залог) Indefinite am is + V3 are Usually houses are built 8 months. Continuous am is + being + V3 are Perfect have + been + V3 has This house is being built now. This house has been already built. Обычно дома Этот дом строится строят 8 месяцев. сейчас. Этот дом уже построен. Past was + V3 were This house was built last year. Этот дом был построен в прошлом году. was + being + V3 were When I came last year this house was being built. Когда я в прошлом году приехал, этот дом строился. Future will + be + V3 This house will be built next year X Этот дом будет построен в следующем году. had + been + V3 This house had been built before I came. Этот дом был построен до того, как я приехал. will + have + been + V3 This house will have been already built by January. Этот дом уже будет построен к Январю. PARTICIPLE Participle I (Present Participle) using Active (использующий) being used Passive (использующийся) Participle II (Past Participle) used (использованный) 103 Perfect Participle having used (использовав) having been used (после того, как использовали) БИБЛИОГРАФИЯ 1. 2. 3. 4. 1. 2. 3. 4. Ануфриева Л.Н., English for Engine - Room Matters (Английский для машинной команды судна)/ Л.Н. Ануфриева, А.Ю. Стрелков. - Владивосток: Учебное пособие "Владивосток", 2004. - 148 с. Колыбенко О.С. Пособие по английскому языку по теме "Engines" для студентов 1-го курса факультета механизации сельского хозяйства/ О.С. Колыбенко. - Горки: БГСХА, 2013. Сидорова И.А., Учебное пособие "Diesel Engine"/ И.А. Сидорова, Е.В. Жигалкина. - Новосибирск: Новосибирская Государственная Академия Водного Транспорта, 2004. - 96 с. Хабина Н. Развитие навыков чтения литературы по специальности для студентов АТ факультета (Английский язык): учебное пособие / Н.К. Хабина, Т.И. Белик. - Челябинск : Изд-во ЮУрГУ, 2004. - 41 с. Электронные источники: Marine Diesels.co.UK.: сайт. - URL: http://www.marinediesels. info/Basics/lubrication_system.htm (дата обращения: 30.09.2019). - Текст: электронный MechStuff: сайт. - URL: http://mechstuff.com/differencesadvantages-disadvantages-of-4-stroke-2-stroke-engine/ (дата обращения: 05.10.2019). - Текст: электронный Quora, a place to share knowledge and better understand the world: сайт. - URL: https://www.quora.com/What-is-the-differencebetween-a-2-stroke-engine-and-a-4-stroke-engine-3 (дата обращения: 22.11.2019). - Текст: электронный Woodford C. Diesel engines / Chris Woodford - Текст: электронный // ExplainThatStuff!: Интернет-портал. - URL: https:// www.explainthatstuff.com/diesel-engines.html (дата обращения: 17.10.2019) 104 Содержание UNIT I TYPES OF MARINE ENGINES ТИПЫ МОРСКИХ ДВИГАТЕЛЕЙ.............................................3 UNIT II DIESEL ENGINE OPERATION AND MAIN COMPONENTS РАБОТА ДИЗЕЛЬНОГО ДВИГАТЕЛЯ И ЕГО ЧАСТИ............8 UNIT III TYPES OF MARINE DIESELS ТИПЫ ДИЗЕЛЬНЫХ ДВИГАТЕЛЕЙ.......................................17 UNIT IV DIESEL ENGINE COOLING SYSTEM СИСТЕМА ОХЛАЖДЕНИЯ ДИЗЕЛЬНОГО ДВИГАТЕЛЯ...31 UNIT V DIESEL ENGINE LUBRICATION SYSTEM СМАЗОЧНАЯ СИСТЕМА ДИЗЕЛЬНОГО ДВИГАТЕЛЯ......36 UNIT VI CONVERSATIONAL TOPICS РАЗГОВОРНЫЕ ТЕМЫ.............................................................41 UNIT VII TEXTS FOR READING, TRANSLATING AND RENDERING ТЕКСТЫ ДЛЯ ЧТЕНИЯ,ПЕРЕВОДА И АННОТИРОВАНИЯ И РЕФЕРИРОВАНИЯ................................................................52 UNIT VIII TESTS ТЕСТЫ.........................................................................................90 СПИСОК СОКРАЩЕНИЙ, ВСТРЕЧАЮЩИХСЯ В ТЕКСТАХ СУДОМЕХАНИЧЕСКОЙ СПЕЦИАЛЬНОСТИ......................97 Сокращения, используемые в инструкциях и современных справочниках по диагностике и ремонту дизельных двигателей...............................99 ГРАММАТИЧЕСКИЕ ТАБЛИЦЫ................................................102 БИБЛИОГРАФИЯ..........................................................................104 105 Учебное издание Сидорова Ирина Анатольевна Иностранный язык DIESEL ENGINE Дизельный двигатель Учебное пособие Компьютерная верстка: Шулика И.В. Подписано в печать 17.05.2014 с оригинал-макета Бумага офсетная № 1, формат 60х84 1/16, печать трафаретная – Riso Усл. печ. л. 6,2. Тираж 100 экз., заказ № . Цена договорная ФГБОУ ВО «Сибирский государственный университет водного транспорта» (ФГБОУ ВО «СГУВТ»), 630099, г. Новосибирск, ул. Щетинкина, 33 Отпечатано в издательстве ФГБОУ ВО «СГУВТ»