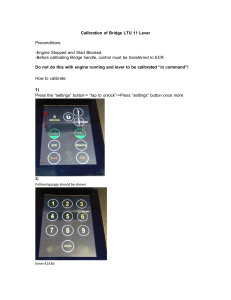

CD B Horizontal Lathe Operation Max. Swing Over Bed: Max. Length Turned: Serial No. : manual Attention Immediately after the arrival of the machine a check should be made for eventual damage due to transportation. Furthermore, please check whether the technical documents, the standard accessories, standard tool and special accessories were completed! If anything damaged, please immediately contact with us without any hesitate. In order to help your correctly use and maintaining the machine from now on, please carefully reads and takes good care of the "operation manual" and other attached technical documents properly. Before the installment and usage, please read "OPERATION MANUAL" carefully and thoroughly. Chinese version of all technical documents in Chinese and English languages is regarded as final Executive standards: JB/T 2322-93 《Technical requirements of horizontal lathe》 OPERATION MANUAL Index The First Page INDEX Ⅰ Mechanical system 1. General introduction-------------------------------------------------1-1 2. Safety regulations -------------------------------------------------1-2 3. Hoisting and Installing --------------------------------------------- 1-7 4. Main Technical Data ------------------------------------------------1-12 5. A brief introduction to structure and feature - -------------------1-13 6. Operation and precautionary measures ---------------------------1-23 7. Maintenance、Conservation and Adjustment -------------------1-25 8. Accessories------------------------------------------------------------1-29 9. Vulnerable parts ------------------------------------------------------1-30 10. Special accessories operation manual----------------------------1-30 Ⅱ Electricity system----------------------------------------------------2-1 1. Machine parts and documents index pls. See Table 1 2. Mounting position of electric parts pls. See Fig.5 3. Mounting position of connecting panel pls. See Fig.6 4. Mounting position of +E-XT1 Pls. See Fig.7 5.Mounting position of push buttons and switches pls. See Fig.8 6. Operation Procedures OPERATION MANUAL Mechanical system Page : 1 -1 Ⅰ MACHINE SYSTEM 1 General introduction 1 Fig.1-1 Machine Profile Fig.1-1 Machine profile 1.2Main Use and Scope of Use This machine can perform various turning operations for all types of parts such as turning external, bevel face, corn, drilling, reaming, boring, all metric and inch, module and diametric pitch thread. It can be applied extensively to mechanical and other industries to do single or batch turning operation. There are a lot of special accessories for the user to choose. 1.3 Main features: Compact structure、 good performance and easy to operate. 1.4 Meanings of the Model Stands for improving sequence number,Usually use A,B Stands for 1/10 Max. Swing Over Bed (Unit: mm) Stands for Series number of Horizontal Lathe (1 means no Gap; 2 with Gap) Stands for series number of design Stands for machine type (ie: First alphabet of Chinese Letters) 1.5 Working Conditions The machine should be connected to right voltage, frequency, and safely grounded. The operator should be trained and qualified. Proper working area is also necessary. OPERATION MANUAL Mechanical system Page : 1 -2 1.6 Environmental Condition The machine should be mounted far away from the water、the fire and other places dangerous to personal safety. The machine should be far away from the vibration source、flammable and high explosive materials. The machine should be far away from poisonous and harmful burning things. In the air there is no excessive dust、sour and corrupt gas and salinity. 1.7 The Influence to Environment The noise acoustic pressure level ≤83db(A) in hollow rotation, no harmful gas or liquid emissions. So, has no harmful influence to the environment 1.8 Safety: This machine is conformed to GB 15760-2004《 Metal Cutting Machine Tool General technical terms of safety protection 》 We are not responsible to the safety of clamps and auxiliary equipment different from those permitted by producers. 2 Safety Explanation The machine has some safety equipment to prevent operators and the apparatus from being injured or damaged. Before starting the machine the operator also should be acquainted with the following regulations. 2.1 The requirements to the persons who operate or maintain the machine. a) The operator should be trained and qualified. Before starting, the operator must read the “Operation Manual” carefully and thoroughly and know well about the functions of name plates. b) Only trained and qualified person could maintain the machine in case of accident. 2.2 Basic Operation Request Dangerous: a) Don’t touch the control panels、transformer、motor、the connecting box, as well as other connection terminal with high voltage. b) Do not use the wet hands to touch the switch, otherwise can create the short circuit, and endanger the personal safety. Warning: a) Be extremely familiar with the position of Emergency button, in order to turn it in any time without thinking. b) Cut off the machine power before inserting in the fuse. c) Turn off the main switch immediately in the case of the power with some problems. d) If a task must complete by two persons or more, a special signal should be set in every procedure, then according to the signal to start the next Caution: OPERATION MANUAL Mechanical system Page : 1 -3 a) Use the recommendation lubrication oil and grease or something with the same capacity. b) Use the appropriate fuse. c) Do not smear、scrape、get off or remove the warning labels. If the handwriting on the label has already become vague or lost, order a new one. d) Provide enough working space to avoid danger. e) Keep the working area clean and dry in order to get rid of being slipped down by water or oil. f) Before operating switches, confirm firstly to get rid of making a mistake. g) Do not touch the switches at will. h) The working table close to the machine should be strong and steady. And pay attention to the work-pieces not let it dropping on the ground and causing danger. 2.3 Requests before putting through the power source Danger: If the electric cable, the coil or the electric wire is damaged, that can cause leakage of power and even lead to an electric shock. Therefore, before use should inspect firstly. Warning: a) Understand the content in the operation manual of every function and operating procedure. b) Wear the insulation shoes、the work clothes 、and other protective facilities. c) Close all the doors or covers of the protecting cover and electric box. Caution: a) The cable between the switch of workshop and main switch of the machine should be strong enough. b) The electric cable expositing on the ground should be protected. c) Lubricate all moving parts before the first starting the machine or lying idle on long time, pull the lubricating pump until the oil leak out from the scraping plate. d) Fill the oil to the oil cup, check the oil on time, if necessity, inject oil. e) As to the lubrication points, the type and volume of the oil please refer to the related name plates. f) Switches and operating handles should be flexible and moving smoothly. g) First turn on the switch of the workshop, then set the main switch of the machine on “on” position. h) Check on the coolant and fill it if necessary. 2.4 Requests after Putting through the Power Source Check the signal lamp whether being light on when the main switch is in “ON” position. 2.5 General Inspection Warning: Don’t put your finger between the belt and the wheel when check the degree of tightness of the belt. OPERATION MANUAL Mechanical system Page : 1 -4 Caution: a) Inspect the motor、headstock and other parts to make sure that there is no unusual noise. b) Inspect the lubrication situation of every part of the machine. c) Inspect the protecting cover and the safety device whether in normal work condition. If the belt being expanded pls. Replace it at once. 2.6 Temperature increment Caution: a) To increase the temperature of the machine, especially main spindle and feeding box, the machine should run on automatically about 10-20 minutes in 1/2 or1/3 of the Max speed to reach a steady temperature increment. b) If the machine has been unused for a long time, do not use it to do processing work immediately but first pre-heated the moving parts of the machine. Otherwise the processing accuracy couldn’t be ensured because the moving parts may be expanded by heat due to not properly lubricated and worn out as the machine lying idle for a long time. 2.7 The Preparations before Start Warning: a) Tools should be conformed to the technical data, size and type of the machine. b) The cutting tools excessively worn or damaged will affect the processing accuracy directly or damage the machine, so before starting should replace these cutting tools. c) The processing area ought to have enough illumination to benefit safety examination. d) The tools and other goods around the machine or the equipment should be set in order, and keep the environment clean and the passing way unimpeded. e) Don’t put tools or any other things on the headstock、tool-post covers or somewhere like these. f) If the central bore of the heavy work-piece is too small it may spring out from the center during loading. So attention must be paid to the size and angle of it. g) The chuck jaws should hold on the work-piece, otherwise they may be thrown away during the speed rotating. 2.8 The Attention paid during working Danger: a) Put on the working cap before start working and don’t wear the long hair loosely. b) The work piece must be clamped firmly. d) Do not touch the rotating work-piece and main spindle by hand or other things. e) When carry on the heavy work-piece processing, should prevent the chip piling up, because the hot chip may cause a fire. Warning: a) Do not wear gloves when turn on the switch, otherwise may cause misoperation. b) Do not open the chuck guard cover during the spindle running. c) Do not shift the speed change lever during the spindle rotating. d) To unload the work-piece only when the spindle stop. OPERATION MANUAL Mechanical system Page : 1 -5 e) Don’t clean the chip during processing. Caution: a) To move the heavy work piece, two persons or more must work together in order to avoid of danger. b) Workers who operate fork lift、the crane or the similar equipment and hook must trained and authorized. c) Don’t knock at the surround equipment when operate the fork lift, the crane or the similar equipment. d) Lifting cable, ring and hook should be strong enough and strictly controlled in safe range. e) Use the brush to clean up the scrap on the tool bit, don’t use bare hands to clean it. f) wear preventive mask in magnesia alloy processing. 2.9 Interrupt Processing Caution: After completing the work and leaving the machine for a while, please set the main switch in “OFF” position, and simultaneously close the main circuit switch as well. 2.10 After the processing over Caution: a) Don’t clean anything before stop the machine. b) Sweep away rubbish, clean the doors and covers, etc. c) set the machine in original position. d) Inspect the scraper whether being damaged, if so, replace it immediately. e) Inspect the coolant and the lubricating oil, if necessity, fill it on time. f) Clean the filter of the coolant box. g) Turn off the main switch, main circuit switch and power switch of the work shop before getting off work. 2.11 Safety Protecting Device a) The spindle chuck guard: it was mounted with travel switch, when open the cover, the machine will stop running at once. To start the machine again, must close the cover first. b) Screw cover: to get rid of rubbish or other things being drawing in or twist in it. c) The longitudinal travel limit pin: top slide limiting screw in longitudinal direction. d) The tailstock block e) The exchange gear cover and travel switch of the electric box. f) Emergency stop button 2.12 Preparatory Work Before Maintenance Warning: a) Do not do any Maintenance work without permission. b) The replacement of spare parts、vulnerable parts(such as seal、oil ring、O-ring、 bearings、oil、grease and so on) should pass through the prearrangement. c) Prepare to record preventive measures and the correct repairing methods. Caution: OPERATION MANUAL Mechanical system Page : 1 -6 a) Read the operation manual carefully and understand the stipulated safety measures. b) Read the relevant contents of operation manual, and make clear of the related principle、 structure and notices. 2.13 Maintaining Danger: a) Anyone who has nothing to do with the maintenance work has no right to operate the main circuit switch and main power. Therefore, hang up with “Do not touch the switch, the machine is in maintaining ” or the similar warning words in these places. This kind of warning words should be obvious, and be easy to take-off but difficult to fall down. b) It is dangerous to do maintenance when the machine is in working condition; in principle, the main circuit switch should be turned off from the beginning to the end during the maintenance. Warning: a) The electricity maintenance work should be undertook by the person familiar with service and also should keep the close contact with the person in charge, do not decide voluntarily. b) Do not remove or alter the travel limiting system、the nearby switch and the function parts including interlock structure. c) Check the ladder or lifter every day under the consideration of safety. d) Use qualified fuse and cable. 2.14 After Maintenance Warning: a) After the maintenance work, do cleaning up the environment; wipe off water and oil on various spare parts to provide good working condition. b) The dismounted parts and the used oil by the cleaning up all should put far away from the machine to guarantee the safety. Caution: a) The maintenance men should inspect whether machine operation is safe or not. b) The data about maintenance and inspection should be recorded and preserved in order to refer in the future. 2.15 Establish Necessary Safety Warning Label Although the machine has used many security inspection protection measures, it still has some potential and unnoticed danger; so, the machine has set up some necessary safety warning labels, such as: the safety explanation label (posted on the exchange gear cover), the safe warning label (posted on the spindle bore), the main spindle warning label (posted on chuck guard cover), the lead screw warning label (posted on the right bed foot) and be careful of an electric shock label (posted on electric box). OPERATION MANUAL Mechanical system Page : 1 -7 3 Hoisting and Installment 3.1 Carriage and store Antirust seal and related vibration and impact prevention measures have been used in machine packing. The machine can be carried and stored in temperature between –10℃ to +55 ℃. 3.2 Hoisting To hoisting the machine must do as specified in Fig. 1-2. When the packing box was lifted by crane, must do according to the lifting mark on the packing box, pay attention to reducing the possibility of cracks and vibration. When moves and lay down, do not let the bottom and the side of a packing box suffer from the impact or the fierce vibration; also do not allow the packing box to incline excessively, its angle of the packing box can not exceed 150 when incline, otherwise, it will affect the precision of the machine. When open the packing box, first inspect the outside of the machine. And then inspect the accessories and tools whether they are complete according to packing list. The unpacked machine should be left by using round steel with the diameter of approximately 45mm, the long 1000mm to pierce” the slinger here” hole (take the lid on the hole away). The collision should be avoided with the lathe being left. Meanwhile, carrying rope should be chosen reasonably and it is forbidden absolutely to tie the rope to protruding lever and axle (especially main spindle). The ragged clothe or wood chip can be put on to prevent from keeping contact directly between the carrying rope and lacquering avoided the lathe damaged. 3.3 Preparatory work Before Installment 3.3.1 Environment requests ( for machine ) The machine should not be installed in the following position: a) The environment where temperature changes obviously, for instance: the machine installing position is nearby heat source. b) Humidity place c) Place of heavy dust and dirty d) Place of vibration source around e) Place of the ground isn’t solid If the machine has to be installed near the vibration source, must dig groove or similar measures to prevent the vibration. If the machine has to be installed on the soft and unsteady ground, must drive a pile to increase the strength of the soil and prevent the machine sunk or inclined. 3.3.2 The Power Connection The power terminal is in the electric box. 3.3.3 The Main Power OPERATION MANUAL Mechanical system Page : 1 -8 Prepare the power line and the grounding line according to the data list, its details see "the electric part of the operation manual”. 3.3.4 Foundation The foundation was shown in Fig.1-3. Before the installment choose a flat place firstly. Then arrange the environment as stipulated and decide the installment space according to the foundation figure and completes the ground. 3.4 The Installation 3.4.1 The Installment Method The temporarily installment the method: It is suitable for small work piece and eccentric work piece. Put the machine on the smooth cement floor directly, hoisting or shovel the machine, then insert the washer or vibration prevent washer (by order) under the adjusting screw to leveling the machine (compare to the " Test Certificate" on the item G1) Fixed Installment Method: a) To lift the machine, put the anchor bolts in the correspondence hole on the bed foot, and let the washer under the adjusting screw. b) Then lay down the machine slowly. Make the anchor bolts enter into the hole according to the foundation diagram. c) To hit the iron plug into the bed foot to complete the rough leveling (compare to the "Test Certificate" on the item G1). d) After the completion of adjustment, fixed the anchor bolts with cement. 3.4.2 The Final Level Adjustment After the solidification of the cement in the hole, adjust the level again. As for the adjusting procedures and tolerance, please see the "Test Certificate" item G1. The minimum graduation of the level-meter is 0.02mm. Note: After the leveling adjustment, must fixed the anchor bolts and adjusting screw tightly to keep the accuracy to be invariable. Check the leveling of the machine 6 months later since the machine mounted. If anything wrong, please correct it and recover the leveling precision. 3.4.3 Inspection The level of the machine is adjusted by adjusting screw (including screws under the bed-foot and the screws between bed and bed-foot) or anchor bolts of chassis. The accuracy data is shown in the test certificate. If the measure results is less than that of the test certificate. It was usually caused in the transportation or installation and adjustment of the lathe. If the lathe was made true appropriately, the higher accuracy may be obtained. OPERATION MANUAL Mechanical system Page : 1 -9 3.5 Inspection The Interior Connection After the work of the level adjustment, do the work below before connecting the machine power: a) The ground connection is correct b) Fixed the screws on the terminal c) See each connector being well tightened. d) Be sure the phase of the power in-putting is correct The inspection of electric system before and after power connection: (refer to the electric part of the <operation manual> 3.6 Inspection Before Test After completing the interior connection, inspect the machine mechanical system according to the stipulation below: a) Cleaning Up The slide surface and some metal surface of the machine were covered with antirust paint to avoid rust. The earth, dust, sand and rubbish are likely to enter into the rust prevent coat in the transportation. So should clean up the rust prevention coat before start the machine. Dip oil on the cloth to clean. After the cleaning up, spread a coat of lubricating oil then. b) Inspection the Machine ∆) Whether there is damage in every machine parts? ∆) Whether there is lost of the components or the accessories? ∆) Whether the machine lubricating parts get lubricated? ∆) Whether the lubricating pipeline is connected completely? 3.7 Testing After the installment, the machine will come to the initial testing run with extremely care. The testing time is about one hour. During the testing time do not use the heavy load to test. Make the lathe run from low to high speed step by step, meanwhile, examine all components, if nothing happens, the lathe just may be used. OPERATION MANUAL Fig.1-2 Hoisting The Machine Mechanical system Page : 1 -10 1 90 11 50 294 900 2 94 X Y 294 1650 450 X 81 4 165 0 197 5 e x t e r i o r o f c h ip p a n c e n tr e of m a c h i n e F ig . 1 - 3 T h e f ou n d a ti o n d ia g ra m d i s t an c e b e t w e e n c e n t r e s +1220 5 00 541 d istance betw een centres 1450 f r o n t e n d o f c r os s s l id e 630 95 0 355 700 475 86 2 38 m a x . e x te r io r o f c r o s s s l i d 825 82 5 981 range of gea r cover B C 16/GB97-76 M16/GB52-76 Y step type 410 240 A- A 1:2.5 B e x te r io r o f c h i p pa n 85 650 washer 330 M16×400 50×50×6 flat type 385 215 85 C t o u g h f o r c o n n e c ti n g w r i n g <5.9" ×5.9" (150×150mm)> 600 OPERATION MANUAL Mechanical system Page : 1 -11 Mechanical system OPERATION MANUAL Page : 1 -12 4 Main Technical Data 4.1 Technical Data Explanation The machine has several kinds of model specifications. When reads this operation manual and other documents, first make clear your machine belong to which kind. 4.2 Main Technical Data Table 1-1 Technical Data Type of the Machine Max. swing dia. Over bed CD6140B CD6240B 420mm 16 1/2” CD6150B CD6250B 500mm 19 3/5” CD6160B CD6260B 600mm 23 3/5” Max. Distance between Centers 950mm(37 2/5”) 1450mm(57”) Max. swing dia.. Over knife rest 225mm 8 4/5” 530mm 21” 325mm 12 3/4” 630mm 24 4/5” 260mm (10 1/4”) 360mm 14 1/6” 730mm 28 3/4” 210mm (8 1/4”) 250mm (9 4/5”) 300mm (11 4/5”) Max. swing dia. In gap Effective length of gap Center height Range of spindle speeds (forward or reverse:15 steps) 22-1800 Dia. of spindle bore 65mm (2 1/4”) Inside taper of spindle bore Metric 1975mm(77 3/4”) rpm 70 Range of longitudinal feeds 0.072-4.038mm(0.0027-0.15 inch) Range of transverse feeds 0.036-2.019mm(0.0013-0.075 inch) Range of metric thread 0.5~28 mm Range of inch screw thread 1~56 t/inch Range of module thread 0.5~3.5 mm Range of pitch thread 8~56 D.P Max. travel of cross slide 305mm (12”) Max. travel of top slide 130mm (5”) 25mm×25mm 1” ×1” Max. size of tool bit holder Inside taper of tailstock sleeve bore Morse No.5 Max. travel of tailstock sleeve 1560 120mm 4.0 Kw or 5.5 Kw or 7.5 Kw 1440r/min or 1730r/min 0.125kw 400 N·m 4100N 1600 1640 1770 1830 1870 2010 2070 2130 Power of main motor Speed of Main Motor Coolant pump motor Max. Torque Max. Cutting Force Net Centers between 1000 weight Centers between 1500 (kg.) Centers between 2000 Mechanical system OPERATION MANUAL Page : 1 -13 5 Machine Structure 5.1 Machine Layout Elec tric box Headst ock Chip pan Apr on box Car riage and t he t ool r es t splash guard Tail st ic k Exchange gear syst em Gear box left bed f oot Foot pedal br ak e mechanism bed r ight bed foot Fig. 1-4 Machine layout 5.2 Brief introduction to the machine parts 5.2.1 Headstock The work piece clamp on the chuck or between the centers and driven by main motor through driven system (see Fig.1-5 Driven system). The power of the main motor is sent by V-belt to the headstock, then pass the gear to main spindle. Headstock is composed of major drive system, feed change over mechanism. Major drive system was incorporated with branch drive chain: At high speed, the chain is quite short (the main spindle components were balanced precisely). The lathe makes little noise and small thermal deformation. The major drive system is operated by lever 26 and 24 shown in Fig.1-9 ( omit after) to obtain 15 speeds which is listed in Table 1-4 The feed changeover mechanism is operated through the small lever 25 lapping over the lever 26 and its motion direction is indicated by the symbol on the lever. The driven system sees Fig. 1-5, the detailed drive components see Table 1-2 The position of rolling bearings sees Fig. 1-6, the detailed rolling bearings see Table 1-3 The type of V belt is A2057 (360mm 14''), A2108 (400mm 16 ''), A2210(500MM 2″, A2286(600MM 24″) 27 26 30 25 23 22 19 18 4 24 1 28 21 31 29 5 3 2 7 20 32-42 66-76 6 9 8 17 12 79 13 10 80 77 81 43 44 46 47 16 14 15 11 78 45 54 51 53 50 52 5 5 58 57 F ig . 1- 5 D r iv e n sy s te m 61 5 9,6 0 56 62 63 49 48 64 65 OPERATION MANUAL Mechanical system Page : 1 -14 Mechanical system OPERATION MANUAL Page : 1 -15 28y 3 27 2 0 ° 56 2 0 ° 29g 2 29y 3 32 2 0° 2.75 30g 27 2 0° 2.5 25 2 0° 30y 31g 2.75 34 2 0° 31y 2.5 45 2 0° 32 2.25 35 2 0° 33 3 27 2 0 ° 34 2 39 2 0 ° 35 2.5 30 2 0 ° 36 3 23 2 0 ° 37 3.25 22 2 0 ° 38 3.25 21 2 0 ° 30 2 0 ° 39 2.25 19 2 0 ° 40 3.25 27 2 0 ° 41 2.25 29 2 0 ° 42 2 60 2 0 ° 2 43 45 2 0 ° 2 44 30 2 0 ° 2 45 29 2 0 ° 2 46g 35 2 0 ° 2 46y 30 2 0 ° 2 47 48 2.5 2 2 0 ° 49 2.5 18 2 0 ° 50 2.5 27 2 0 ° 51 2.5 60 2 0 ° 52 2.5 18 2 0 ° 53g 2.5 60 2 0 ° 53y 2.5 59 2 0 ° 54 2.5 13 2 0 ° 55 2.83 13 2 0 ° 56 2.83 Rack 2 0 ° 57g 6 1 30° 57y 4/1″ 1 3 0 ° +0.33 -0.48 + 0. 2 + 0. 5 0 +0 . 7 8 - 0. 2 +0 . 6 2 - 0 .2 0 - 0 .0 7 + 0 .8 0 + 0 .1 7 0 + 0 .5 + 0 .7 2 + 0 .0 4 - 0 .8 + 0 .0 4 + 0 .0 4 + 0 .8 + 0 .8 8 + 0 .8 0 0 0 0 0 + 0 .0 6 + 0 .6 3 + 0 .4 6 0 0 0 0 58g 6 1 30 ° 58y 4/1″ 1 30 ° 59g 5 1 30° 5/1″ 59y 1 30° 1 30° 60g 5 60y 5/1″ 1 3 0 ° 61 2.5 1 7 2 0° 62g 5 1 3 0° 62y 5/1″ 1 3 0° 63g 5 1 3 0° 63y 5/1″ 1 3 0° 64g 5 1 3 0° 64y 5 /1 ″ 1 3 0 ° 65g 5 1 30° 65y 5 /1 ″ 1 3 0 ° 66 2 . 2 5 40 2 0 ° 67 3 32 2 0 ° 68 2 48 2 0 ° 69 2. 5 40 2 0 ° 70 3 32 2 0 ° 71 3 . 2 5 32 2 0 ° 72 3 . 2 5 32 2 0 ° 73 2 . 2 5 48 2 0 ° 74 3 . 2 5 32 2 0 ° 75 2 . 2 5 48 2 0 ° 76 2 58 2 0 ° 77 2 45 2 0 ° 78 2 60 2 0 ° 79g 2 58 2 0 ° 79y 2 49 2 0 ° 80 2 21 2 0 ° 81 2 rack 2 0 ° fa cto r Deformation Pressure angle Gear qty Module or Pitch NO. fa cto r Deformation Pressure angle Gear qty +0 . 2 6 0 +0 . 2 6 +0 . 2 6 0 +0 . 2 6 0 0 0 0 0 0 0 0 +0 .2 1 8 0 + 0. 7 0 0 0 0 0 0 -0 . 2 6 - 0. 2 0 0 0 +0 . 2 6 0.2 0.2 0 0 + 0. 2 +0 . 1 1 0 Module or Pitch Deformation 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° 2 0° NO. Pressure angle 35 42 29 46 40 52 26 45 56 37 20 36 36 62 18 65 34 52 38 38 62 44 44 56 56 76 72 96 38 36 48 42 42 66 66 35 fa cto r Gear qty 3 1 3 2 3 3 3 4 3 5 3 6 3 7 3 8 3 9 3 10 3 11 2 12 2 13 3 14 15 3.5 16 3.5 3 17 2 18 2 19 2 20 2 21 22A 2 22BC 2.25 23A 2.25 23BC 2.5 24A 2 24B 2.25 24C 2.25 25A 2.25 25B 2.5 25C 2.5 26A 2 26BC 2.25 27A 2.25 27BC 2.5 28g 2 NO. Module or Pitch Table 1-2 the detail list of drive component 〔g:for metric lathe , y:for inch lathe ,A:for 360(14″) and 400(16″)lathe, B:for 500(20″) C:for 600(24″)lathe〕. 0 0 0 0 0 0 +0 .0 8 0 0 0 0 0 0 0 0 +0.71 -0.25 +0.04 -0.1 +1 -0.2 +0.13 -0.29 +1 +0.61 0 0 0 -0.8 +0.8 -0.45 0 32 31 19 18 1 21 20 2 17 15 9 8 3 16 13 7 4 22 24 25 29 23 27 28 30 10 12 6 41 42 F ig . 1 - 6 Th e p o s iti o n o f ro ll i n g b e a ri n g s 26 5 39 38 40 37 43 OPERATION MANUAL Mechanical system Page : 1 -16 OPERATION MANUAL Mechanical system Page : 1 -17 Table 1-3 bearing list M odel 609 6003 6004 6005 6005 -RS 6007 6009 6190 6 6206 6305 6306 6210 6305 N 1 6002 51102 51104 51204 234 420/SP 5 NN 3016 K/P5 NN 3020 K/P5 S pecific ation 9× 24× 7 17 ×35 ×10 20× 42× 17 25× 47× 12 25× 47× 12 35× 62× 14 45× 75× 16 30× 47× 9 30× 62× 16 25× 62× 17 30× 72× 19 50× 90× 20 25× 62× 17 15 ×32 ×8 15 ×28 ×9 20× 35× 10 20× 40× 14 10 0×1 50× 60 80× 125× 34 10 0×1 50× 37 Sty 1 1 1 5 3 4 2 1 3 3 2 2 1 1 1 3 1 1 1 1 N o . ( i n f i g 1 - 6 ) Remar k 19 23 103 24 104 26 1 3 , 1 5 , 2 0 , 3 1 , 3 2 105 1601 05 1 8,1 9,3 0 107 2 1,2 7,2 8, 29 109 2 2,2 5 1000 906 37 206 2 ,7, 17 3 05 3 ,4, 16 3 06 5 ,6 6 0210 1 50 305 8 7 000102 39 8 102 40 8 104 3 8,4 1,4 2 8 204 43 D2268 120 10 D3182 116 9 D3182 120 12 Table 1-4 table of spindle speed A B C D E 18 00 70 6 27 0 1 07 41 1 305 512 19 5 30 78 Symbol of lever 26 to center 9 56 375 14 3 57 22 Symbol of lever 24 to center Z1 Z2 Z2 Z1 Z1 Z2 1 3 2 138 1156 1 1163 14 118 1 234 258 238 214 2 212 434 512 11 22 44 6 514 10 12 21 42 5 24 23 10 26 2 7 13 1 312 24 23 1 112 12 1167 278 8 312 3 3 14 38 11 1 58 116 3 1 12 16 4 2 1 7 134 3 4 5 6 7 8 9 10 11 2 3 4 5 6 7 8 2.2 5 2 .3 75 2.5 2.625 2.75 2.87 5 3 9 mm 10 11 3 .2 5 3 .3 75 3.5 1.1 25 1 .1 87 1.25 1.312 1.37 5 1.43 7 1 .5 1 .6 25 1 .6 87 1.75 18 9 19 9 .5 4 .5 4 .7 5 20 10 5 21 22 10.5 11 5.2 5 5.5 23 2 4 26 27 28 13 .5 14 6.5 6.75 7 3.25 3 .3 75 3 .5 1 1.5 1 2 13 5 .7 5 6 2.25 2.37 5 2.5 2.62 5 2.75 2.87 5 3 1.125 1.18 7 1.25 1.31 2 1.37 5 1.43 7 1 .5 1.625 1 .6 87 1.75 0.5 0.562 0.59 3 0.62 5 0.65 6 0.68 6 0.71 8 0 .7 5 0.812 0 .8 43 0.875 1 2 1 3 6 16 64 14 28 56 11 2 πm 0 .5 0.5 62 0 .5 93 0.62 5 0.656 0.68 6 0.71 8 0 .7 5 0 .8 12 0 .8 43 0.87 5 1 6 52 5 4 48 10 46 9 1/n" 8 534 28 56 11 13 1 3.5 14 26 2 7 52 5 4 9 π/n" 7 12 48 8 46 7 11 1 1.5 22 44 6 5 10 912 412 9 8 3 20 40 4 19 38 3 2 0 21 4 18 2 16 1 36 9 .5 1 0 1 0.5 9 8 32 19 4 0 42 18 38 16 5 36 4 32 3 2 1 2 F 3 2 G E G 1 1 E F T a b l e 1 - 5 t a b l e o f th r e a d OPERATION MANUAL Mechanical system Page : 1 -18 Z1 Z2 Z2 Z1 Z1 Z1 Z2 Z2 E E 0.324 0. 2 8 8 1 2 3 0. 09 6 0. 10 2 0.108 0.054 0. 04 8 0. 05 1 0. 04 3 0.117 0.056 0.028 0.0135 0.014 0. 01 2 0. 01 27 0.027 0.0067 0.007 0. 02 4 0. 02 35 0. 08 5 5 3 . 3 17 3. 1 7 3 6 in ch 7 Th e in ch l at h e 1 . 6 58 0 . 8 82 9 0 . 4 15 0 . 2 07 0 . 1 04 7 1. 5 8 6 0. 7 9 3 0. 3 9 7 0. 1 9 8 0. 0 9 9 6 8 3 . 46 1 1 . 73 1 0 . 86 5 0 . 43 3 0 . 21 6 0 . 10 8 8 9 3 . 7 50 1 . 8 75 0 . 9 37 0 . 4 69 0 . 2 34 0 . 1 17 9 10 3 . 89 4 1 . 94 7 0 . 97 4 0 . 48 7 0 . 24 3 0 . 12 2 10 11 4 . 03 8 2 . 01 9 1 . 01 2 0 . 50 6 0 . 25 2 0 . 12 5 11 0.118 0.059 0.128 0.139 0.064 0.069 0.061 0.125 0.032 0.035 0.031 0.145 0.072 0.036 0.150 0.075 0.0374 0.0187 0.0147 0.0153 0.016 0.0174 0.018 0.029 0.0093 0.0073 0.0077 0.008 0.0087 0.009 0.0034 0.0035 0.0037 0.0038 0.004 0.0043 0.0045 0.0047 4 3. 0 2 9 1. 5 1 4 0. 7 5 7 0. 3 7 9 0. 1 8 9 0. 0 9 5 5 mm 0. 00 6 0. 00 64 0. 00 3 0. 00 32 3 2 . 8 84 1 . 4 42 0 . 7 21 0 . 3 60 0 . 1 80 0 . 0 90 4 0. 02 7 0. 01 07 0. 00 54 2 3 0. 00 27 1 2 2.596 2. 3 0 8 1 2 . 74 0 1.298 1. 1 5 4 2 F 1 . 37 0 0.649 0. 5 7 7 0 . 68 5 0 . 34 2 0 . 17 1 0 . 08 6 3 1 3 0.162 0. 1 4 4 2 2 0.081 1 0. 0 7 2 G G 1 3 F The me t ri c l at h e T ab le 1 -6 : tab l e o f f e ed s 1/ 2 OPERATION MANUAL Mechanical system Page : 1 -19 OPERATION MANUAL Mechanical system Page : 1 -20 5.2.2 Exchange gear mechanism It is incorporated with slide gear structure. Turn off the power and loose screws inside the exchange gear cover and screws in the exchange gear cover. Push or pull the slide gear to the position shown in Table 1-5 by hand (the empty revolution of the gear is less 0.1mm). Fixed the above loosen screws and try to turn the exchange gears and see it run flexibly, and four kinds of threads about metric, inch system, module and diametric pitch can be transformed each other. 5.2.3 Feed box Feed box is consisted of basic thread pitch changeover mechanism, multiplying mechanism and metric, inch thread changeover mechanism. Basic thread pitch changeover mechanism is operated through lever 21, so do multiplying mechanism through 22, and metric, inch thread changeover through lever 23. The thread was listed in table 1-5, cutting feed volume was listed in table 1-6. 5.2.4 Carriage It consists of thread cutting mechanism, longitudinal, transverse manual and automatic operation system, and rapid moving system. The machine type of 950mm and 1450mm with rapid motor is supplied by order. The position of levers shown in Fig.1-9 and its relationship in the nameplates of the carriage. a) Thread cutting: lift up the lever20 to the open position; lever14 in the middle neutral position, then operate the lever11. b) Longitudinal, transverse manual feeding: lever11, 20 up to open position, lever14 in the middle neutral position, operate the lever8 to perform the longitudinal feeding and lever9 for transverse feeding. c) Longitudinal, transverse automatic feeding: if handle wheel8, 9 with folding knob, must fold the knob in the wheel before rapid feeding or automatic feeding. First lever11 up to open position; then to choose longitudinal or transverse feeding by lever14, finally use lever20 to get automatic feeding. d) Rapid moving system: rapid movement can complete by rapid motor to directly drive the carriage in longitudinal and cross slide in transverse direction. First lift lever11、20 to open position, then choose longitudinal or traverse feeding by lever14, finally push button12 to get the rapid moving. 5.2.5 Footbrake mechanism and electric braking device Action of footbrake mechanism is the same as that of electric braking device. User can choose one in respond to the requirement. While the footbrake mechanism cut off power by footboard 19 through lever mechanism, the braking belt tightens the wheel on the axis of motor, consequently the lathe stop quickly. 5.2.6 lubrication systems The lathe should be lubricated and cleaned fully to keep it high accuracy and long enough life. All cups on the lead screw clutch, slide and tailstock can be lubricated by oil gun. The high melting grease should be added to the bearing on lubricating position of the exchange gear every 50 hours (type of recommendation: ZL-4/SY1412-75)..The lead screw should be cleaned, and injected oil with oil gun before cutting thread, So do smooth rod and slide guide. The guide can also be lubricated by pump on the carriage. Mechanical system OPERATION MANUAL 1000h 1 2 3 50h 8h Page : 1 -21 4 7 6 5 8 o p e ra ti o n t im e F ig u r e . 1 - 7 l u b r i c a t i n g fi g u r e Table 1-7 lubricating table lubricating points lubricating modality lubri- 1 2 3 1000 1000 1000 4 5 6 7 8 8 8 8 8 # 46# 2 cating methods change oil ( hour) refill if necessary(h) lubricating or operating(h) lubricating oil quantity (cm 3 ) 50 32 # # 46 4500 46 # 2500 46 # # 46 2 # 46 4 journey 46 2 Mechanical system OPERATION MANUAL Page : 1 -22 First oil replace is done after working approximate 300hrs. of the headstock, feed box, oil tank (only with the machine with outside cycle lubrication system) and carriage .And afterwards do as specified in Fig.1-7 and Table 1-7 5.2.7 Cooling System As shown in Fig.1- 8, cooling box was mounted on the right bed foot of the lathe. Open the side lid of the right bed foot, cooling box can be easily taken out. Cooling liquid usually should be 2/3 height of the cooling box. The detailed table of cooling components is listed in table1- 8. Table1-8 The detailed table of cooling components Name Type Specification No. 1 Cooling pump 2 steel wire knitting rubber tube 3 4 5 Internal screw Externall screw li b plastic Transparent rubber tube 3 AOB2-25 C li A72-7/G74-1 13×21×L/M22×1.5 L81-3 G3/8" JR101 G3/8" ×15×650 A75-4 φ25×3×L Dia:950/1450/1975 L :1700/2100/2500 Dia:950/1450/1975 L :1000/1000/1500 4 2 1 r igh t foo t oil p lat e 5 co olin g bo x Fig.1-8 cooling system Note Mechanical system OPERATION MANUAL Page : 1 -23 6 Operation and precautionary measures 6.1Operation Starting and the operation procedure in processing, stop procedure, the operating methods and attention shown in the (Electrical Part) of the <operation manual> The diagram of operation position was shown in Fig.1-9, the description of action was listed in table 1-9. 6.2 Precautionary measures a) Before starting the lathe, read the OPERATION MANUAL carefully, clean and lubricate it fully as specified. b) Operated rod 18 should be placed on the middle position before the main switch1 being connected. The emergency button 6 and quick feeding button 12 should be opened c) To change main spindle speed should be done after the lathe stopped, it’s forbidden to shift the speed change lever in spindle running. Feed change, lead and smooth rod choice should be operated at low speed or after the lathe stopped. Point movable button5 can be used to make the operation become easy. d) As the lathe was equipped with brake or treadle braking apparatus, don’t break it by reversing. e) Brake braking frequency ≤5 times /min. f) Face plate velocity ≤the number marked on head stock.. It is forbidden to use the face -plate and chuck whose diameter is larger than stipulated in the packing list. When the chuck run at high speed, its jaws must hold the work-piece to avoid the jaws may fly out from the chuck. g) Cutting feed was listed in table 1-10 at high speed. el ec tri c s tati on( fla t lath e) 2 3 4 5 6 1 7 8 9 27 20 10 11 12 13 14 15 16 26 25 24 23 22 21 5 2 6 3 4 19 18 e lec tr ic stat ion( s tep l athe) Fig. 1-9 operation position of the operating components 17 OPERATION MANUAL Mechanical system Page : 1 -24 4 Table 1-9 The description of the action of operating components Name Illuminate to the action Main switch With the switch turn the power on or off Power pilot lamp With the lamp indicate whether the lathe to be on or not Cooling switch With the switch control cooling pump The electric brake will be closed or opened after main motor Electric braking choice switch turning off (you can choose either this way or item 19) 5 6 7 8 9 10 Point moveble button Emergency stop button Lead screw & rod select lever Longitudinal feed hand-wheel Transverse feed lever Cutter saddle locking lever No. 1 2 3 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Make main spindle to turn around discontinuous With the switch make the lathe stop quickly in case of emergency With the lever to choose feed or screw machining With wheel move carriage in longitudinal direction With the lever move carriage in transverse direction. With the lever lock cutter saddle. With the lever control half-nut (lever 14 must be in Half-nut control lever empty gear) to be continued… Rapid moving button (option) Make the carriage move quickly when required. Upper slide lever (option) With the lever move upper slide board. Longitudinal & transverse feed Choose feed in longitudinal or transverse (lever 11 choice lever must be in the separate position) Sleeve tightening lever With the lever tighten the tailstock sleeve. Tailstock locking lever With the lever tighten the tailstock. Sleeve moving hand-wheel With the hand-wheel move tailstock sleeve. Main spindle forward-reverse Control main spindle to make it run forward or operated rod reverse. Foot brake board (machine with it) Cut off power at once and stop the machine. Feed rod clutch operating With the lever control sliding clutch and choose handle longitudinal or transverse feed. Basic group operated lever With the lever transform basic group pitch. Multiplying thread operated lever Multiply the thread pitch Handle of category with worth Make an exchange between metric and inch worth thread selector thread. Main spindle speed change lever With the lever to change the speed of the Main spindle Lead screw & rod select lever With the lever to choose feed or screw machining Main spindle speed change lever lever of the lubrication pump With the lever to change the speed of the Main spindle Lubricating the guide-way by force. Table 1-10 cutting speed Spindle r/min speed Range of feed mm/r(inch/r) 706 956 1305 1800 ≤1.14(0.0575) ≤1(0.0503) ≤0.8(0.0403) ≤0.61(0.0308) OPERATION MANUAL Mechanical system Page : 1 -25 7 Maintenance, conservation and adjustment 7.1 Daily conservation a) Before doing work every day, lubricate the machine fully to ensure it can be started under normal condition. b) After finishing work every day, sweep up and remove cutting washer and clean all part of the machine, daub rust protection oil on it. c) Take care of centers, axle neck of main spindle which fixed chuck and guide-way to keep the lathe have a high processing accuracy. d) Lubrication oil should be often injected between slide block and work-piece when steady rest and follow rest being used. To ensure satisfied accuracy, adjust the slide block and work-piece at any time as required. e) To prolong the working life of lead screw and half-nut, use the half-nut only in screw cutting (lubricate the half-nut before use). f) Something happen while the lathe work, stop to examine it. 7.2 Everyday checking Table 1-11 Everyday checking No. Check point 1 Oil level indicator 2 Coolant level 3 Guide ways 4 5 6 7 8 9 10 11 Checking item Remarks Is oil under rated level? Is oil polluted? Is coolant at the proper level? Is coolant polluted? Is chip pan filter jammed? Are the guide-ways well lubricated? Add oil if necessary Renew oil if necessary Add if necessary Renew if necessary Clean it if necessary Start the oil pump to add lubricants until oil leak from the scraper Are the chip scrapers damaged Are they too tight or too loose? V-belts Are they in good condition? Pipes and outline of Is there any oil leakage? Is there any coolant leakage? the lathe Any noise or vibration? Moving parts Are they moving smoothly? Safety devices Are they working well? Any break? Wires and cables Is the insulating material damaged? Motor, gear boxes, Any noise or vibration? and other turning Do they have excessively high parts temperature? Add lubricant to the jaws Chuck lubrication Working condition Is the precision of the machine of the machine within allowed tolerance Do weekly Compare to item p1 of <test certificate> OPERATION MANUAL Mechanical system Page : 1 -26 7.3 Periodical Checking Table1-12 NO 1 2 3 Check point Lubricating Lubricating devices system Pipes Filter Cooling system Chip pan V-belt Belts Pulley 5 Chuck Chuck 6 Operation panel Electrics and wire fixing screws 8 Electrics 9 Foundation Any time when necessary 6 months Check against any abnormal noise from the bearings, etc. 6 months Temperature increment, Clean the pulley insulating resistance Main motor 7 Clean the chip pan Renew coolant, clean the filter and the tank Outline and tightening or loosing check. Clean the pulley Noise, vibration 4 Connection between parts Maintaining item Time Clean the filter 1 year Check against leaking jamming and 6 months breaking. Connection between electric box and other Limit switches, sensors, and electromagnetic valves Take apart the chuck, get rid of chips if any Check if the components give off any odor, or take on any abnormal color Check against any wearing-out and if any screw is loosen Clean dirty things Check and tighten fixing screws Check and tighten screws fixing on relay and terminals Check and tighten screws fixing the elements and wires on them. Check working condition while the machine is running Check the leveling situation of the guide ways with a level meter, and readjust if necessary. 1 year 6 months 1 month 6 months 6 months 1 month 1 year 7.4 Adjustment 7.4.1 Pre-fastening and replace of the V-belt General inspection should be made so as to keep the v-belt with some pre-fastening tension. Otherwise, it will be worn out quickly. Therefore, check it regularly. The method is: press down the v-belt about 5 mm by thumb appropriately. Otherwise it needs to adjust. Adjust the V-belt regularly according to the following procedures: 1) pull the belt in the vertical direction of the wheel and the force must be in the middle of the two wheels.2) fix the four mounting bolts on the pedal of the motor. 3) Turn the adjust bolts and move the pedal of the motor to let the V-belt have proper degree of tightness. First adjustment is done after 3 months of the machine installed, afterwards, adjust every 6 months. When the V-belt is required to be replaced, so do a couple of V-belt with same size and specification. Mechanical system OPERATION MANUAL Page : 1 -27 7.4.2 Adjustment of the Headstock If the cylinder gauge doesn’t conform to that of the certificate (item b p1), examine the parallelism between center’s line of headstock and the guide-way, and adjust it as follows: As shown in Fig.1-10, unfasten 4 bolts on the headstock, adjust two hexagon head bolts on the part (1), revolve the headstock on the horizontal position, and adjust its center’s line. After adjustment, refasten all bolts and nuts, examine again to be sure it is pretty good. (refer to item G7 of the < test certificate>. 3 2 3 00 A B 1 Fig. 1-10 Adjusting the headstock accuracy 7.4.3 Adjustment of main spindle bearings If the main spindle bearings gap is too big, it will influence the processing precision directly. There are two kinds of spindle accuracy that is radial run-out (item G5) and axial slip (item G6) which are guaranteed by front and hind bearings, and usually adjusted to be ready for use before leaving the manufacturer. If the spindle must be adjusted because of being knocked by tool rest or other reasons, please adjust the front and hind bearings of main spindle simultaneously and also separately as requirement. The method was shown in Fig.1-11, The front bearing adjustment: unfasten screw 3, adjust nut 4 as required then refasten the screw 3.The hind bearing adjustment: unfasten nut 1, adjust nut 2 as you need, and refasten nut 1.After adjusting the major bearings, let the machine run around 1 hour without loading, then examine its temperature increment. General temperature rise are 25℃-40℃. The temperature contrast between the front and hind bearings is usually less than 10℃. The temperature of spindle bearings is not allowed to exceed 70℃, otherwise, loosen the nut slightly. OPERATION MANUAL 1 2 3 Mechanical system Page : 1 -28 4 Fig. 1-11 Main spindle bearings adjustment 7.5 Common trouble analysis and solutions Table 1-13 Common trouble analysis and solutions Reason Analysis Solutions Remarks The plug of cooling pump hasn’t Inspect and completely inserted in the coolant repair The chip pan filter and the pump filter Inspect and being jammed repair Coolant doesn’t come The coolant switch on the operating panel Inspect and out doesn’t work normally repair The cooling pump motor doesn’t work Inspect、repair The connecting wire of the coolant pump Inspect and motor falling off repair The internal lubrication of the headstock inspect The temperature of is not proper. headstock increased The main spindle bearings being Inspect and strangely tightened too much. adjust Oil leaking from some lubrication point Inspect、repair No oil in the lubrication Inspect、repair Replace new one system or some Pipe connector jammed Fill the oil as lubrication points No enough oil in the lubricant tank Inspect stipulated Spindle centered improperly in disc processing Inspect、adjust Taper appears in the Tailstock centered not well in shaft Inspect and processing adjust precision processing The installing accuracy doesn’t conform Inspect and to the requirements. adjust The tailstock sleeve is The improper lubrication of the tailstock Inspect and motionless may cause it to be jammed. adjust The tailstock body Jammed due to improper lubrication of Inspect and cannot move normally the moving parts of the tailstock body. adjust Problems Mechanical system OPERATION MANUAL Page : 1 -29 8 Accessories 8.1 Standard accessories No. Table 1-14 Name Specifications/marks Unit Qty. MT5 Pc. 1 Remarks 1 Dead center 2 Washer CDB80121A Pc. 8 3-Jaw chuck K11 200/C6 Pc. 1 For “flange ” machine use 3-Jaw chuck K11 250/D6 Pc. 1 For “cam-lock” machine use 3 4 Transverse feeding lever Pc. 1 (No:4-8-39) 5 Longitudinal feed hand-wheel Pc. 1 (No:4-1-7) 8.2 Tools supplied with the machine Table 1-15 No. Specifications/marks Unit Qty. Name 1 Socket spanner CDB80032A Set 1 2 Socket spanner CDB80033A Set 1 3,4 Single ended open spanner 17; 36 Pc. 1 5,6 Double ended open spanner 10×13;19×24 Pc. 1 7-10 Inner-hexagon spanner 5;6;8;10 Pc. 1 11,12 Hook spanner 85-105;110-130 Pc. 1 13 Oil gun Pc. 1 Specifications/marks Unit Qty. 8.3 Special accessories No. Remarks For “cam-lock” machine use (supplied by order) Table 1-16 Name Remarks 1 Center sleeve CDC80022 Pc. 1 2 Dead center MT5 Pc. 1 3 Live Center MT5 Pc. 1 4 Washers against vibration Pc. 8 5 Longitudinal auto trip Set 1 In the machine 6 Steady rest Set 1 In the machine 7 Back tool rest Set 1 In the machine 8 Taper copy ruler Set 1 In the machine 9 4-position longitudinal auto trip Set 1 In the machine 10 Follow rest Set 1 In the machine 11 Transverse stop Set 1 In the machine 12 Thread dial Set 1 In the machine 13 Driving plate Set 1 In the machine 14 4-jaw chuck Set 1 15 Face plate Set 1 OPERATION MANUAL Mechanical system Page : 1 -30 9 The Vulnerable parts 9.1 Detailed List of Vulnerable Parts Table 1-17 vulnerable parts No. Name No. or specification Material Qty. Remarks 1 Brake belt CDB10201A Asbestos brake belt 1 For foot brake use 2 2 2 Exchange gears (No.3-7-3) Exchange gears (No.3-7-18) Exchange gears (No.3-7-3) Exchange gears (No.3-7-18) Exchange gears (No.3-7-3) Exchange gears (No.3-7-18) CDB30711A For 360 CDB30709A and 400 CDB30712A For 500 CDB30710A CDC30701 For 600 CDC30702 9.2 Vulnerable parts are shown in Fig.1-12 37 δ4 4 00 Fig. 1-12 Vulnerable part: Brake belt 10 Special accessories operation manual 10.1 Thread dial: First see the lathe you purchased in which type, to cut the inch thread by inch lathe or metric thread by the lathe, please refer to the following appendix table. If to cut the metric thread by inch lathe or inch thread by the metric lathe, they can only be performed by run the spindle forward or reverse that is the half-nut keeping in touch. Loose the nut fixed in the frame of thread dial, let the helical spur gear touch the lead-screw, meanwhile, adjust a mark of the thread dial point to the base mark (it can be obtained by moving the carriage). Then refasten the nut and open the half-nut, move the carriage to the proper position, the preparation of thread cutting is ready. Mechanical system OPERATION MANUAL Page : 1 -31 Pls. Cut thread according to the table 1 attached, remember how many marks the thread dial turned, then close the half-nut when the base mark point to the mark of the thread dial turned, the thread cutting can be repeated. Loose the nut, and remove the thread dial when it is not required. 10.2 Inch thread dial: Appendix Table 1 table of thread dial used in cutting inch thread with inch lathe (pitch of 1 screw is ”) 4 Gears of 1 /n" Name plate the (8marks/ round) Helical Remarks spur Marks turned gear 56,48,40,32,28,24,20,16,12,8,4 0 54,52,46,42,36,26,22,18,14,10,6,2 1 44,38,27,23,21,19,13,11,9,7,5,3,1 2 1 1 1 1 1 1 1 1 1 1 13 ,11 ,10 ,9 ,6 ,5 ,4 ,3 ,2 ,1 2 2 2 2 2 2 2 2 2 2 3 3 1 3 1 3 1 3 1 6 ,5 ,5 ,4 ,3 ,2 ,2 ,1 ,1 , 4 4 4 4 4 4 4 4 4 Needn’t use thread dial 16 4 8 10.3 Metric thread dial Appendix table 2 Index list of thread dial (pitch of the lead-screw is 6mm) (21 gears gear is prepared by users themselves.) In Metric thread cutting by metric lathe. mm 0.5,0.75,1,1.5,2,3,6, Name plate (20marks/ round) Name plate (21marks/ round) Marks turned(Z=20) Marks turned(Z=21) Needn’t use thread dial Needn’t use thread dial 2.25,4.5,9,18 3 4,8,12,16,24 4 1.25,2.5,5,10,20 5 1.75,3.5,5.25,7,10.5,14,21 7 ** Other threads can only be processed by run the spindle forward or reverse that is the half-nut keeping in touch.