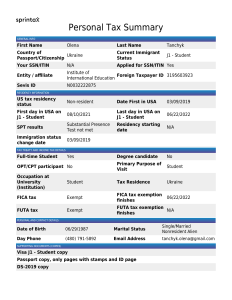

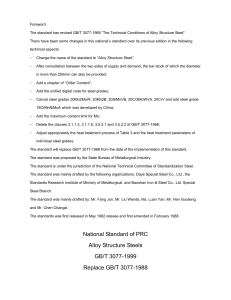

Influence Carbide Forming Element on Mechanical Characteristic by Steels Zohidjon Abdukahhorova) Namangan Institute of engineering and technology, Namangan, Uzbekistan a) Corresponding author: zohidjon55@mail.ru Аbstract. The basic operational and technological properties of steel are defined (determined) by the contents of their chemical elements. Elements allow reaching (achieve) necessary hardening of a firm solution. One of the possible variants of the improvement to technologies and improvements official characteristic thermal processed product - a use the thermal processing with frequentative heating, including with phase fart hard phase. These modes include first fart to hard phase with heating before extreme temperature, residing for steel in region 1100-1150 S. Under this temperature of the heating not only occurs dissolution an carbide phases, but exists dissociation and begin dissolution refractory phase. In clause the decision these problems is considered. Keywords. Technological properties, hardening, defect of a crystal structure, stability, particles, durability, viscosity, stability(resistance), micro distortions, size of bocks, deterioration, thermal processing. INTRODUCTION The determining value in the formation of the characteristics of the structural strength of the materials of the working mechanisms of technological machines is, as is known, the variation of the structural state. The possibilities of changing it by traditional methods of volumetric heat treatment are almost exhausted. At the same time, the regulation of the final structure opens up new horizons due to the directed change of the starting (initial) structure immediately preceding the implementation of the final heat treatment stage. This can be achieved by implementing known or developing original schemes and modes of heat treatment at the preparatory stage of heat treatment. One of the possible options for improving the technology and improving the service properties of heat-treated products is the use of heat treatment with multiple heating, including phase recrystallization [1]. One of the possible options for significantly improving the service properties of heat – treated products is the use of heat treatment with repeated phase recrystallization. Cyclic heat treatment has been most fully studied and has found practical application. Its essence consists in a sharp acceleration of diffusion processes due to alternating heat exchange. If the cyclic processing is carried out with multiple phase recrystallization, then there is a rapid grinding of the grain and on this basis an increase in the yield strength, impact strength [2]. Accordingly, the total heat treatment time is significantly reduced. During cyclic processing with heating to subcritical temperatures, the acceleration of diffusion processes leads to rapid coagulation of cementite plates with the formation of granular structures [3]. However, the introduction of alloying elements into steel that slow down the diffusion of carbon in ferrite significantly reduces this effect. An increase in the density displacement depend on cyclic heat treatment, is also observed, which should be associated with the development of micro plastic deformation during sudden heat changes. The increase in the displacement density depends on the temperature-time conditions of cycling, the possibility of inheritance of elements of the sub microstructure during a new heating-cooling cycle [4]. However, after the final quenching and tempering, the density of displacement does not differ much from that obtained after quenching and tempering according to normal modes. Currently, a large number of methods of thermocycler processing have been developed in relation to certain alloys [5]. Another way to sharply accelerate diffusion processes is to increase the process temperature. In the sixties of the last century, a number of works were devoted to the acceleration of chemical-thermal, thermal treatments by using high-temperature processes. However, these processes had clearly negative sides – this is the growth of grain, an increase in the fragility temperature, etc. Therefore, heat treatment with double phase recrystallization seems to be a more acceptable process [7]. In particular, in the same years, Japanese patents were published, which described the double hardening of ball bearing steel, which increased the durability of ball bearings several times. This was explained by the grinding of grain and secondary carbides of steel. More complete researching on the formation of the steel structure during heat treatment with double phase recrystallization have shown that there are optimal modes that ensure the grinding of austenitic grains, the dispersion of excess phases and the maximum displacement density [8]. The main operational and technological properties of steels are determined by their alloying. Alloying allows achieving the necessary hardenability, hardening of the solid solution, hardening due to the dispersion of the second phase. Alloying elements in die steel, for hot deformation, provide resistance to coagulation of particles of the second phase (carbides). In particular, the strength, viscosity, and heat resistance directly depend on the amount and dispersion of carbides, their resistance to coagulation during heating, as well as on the elements of the fine structure of the structure: the size of the blocks, the level of micro-distortion, the density of dislocations and the degree of their fixation. EXPERIMENTAL PART Increasing the wear resistance and reducing the softening of die steels is achieved by introducing 3-5 % carbideforming elements, nickel and chromium are introduced to increase the hardenability and grinding of grain. In this case, not only carbides of the M3C type are formed in the steel , but also M23C6 , M7C3, M6C, M2C, MC. Since the coagulation of carbides occurs after the decomposition of martensite, the dissolution of small carbides of the M3C type, the increase in resistance to coagulation is associated with the formation of carbides MC (VC) and M2C (Mo2C or W2C) [1]. The stability of carbides of the M6C (Fe3Mo3C) type is somewhat less. Carbides of the M7C3 and M23C6 types (Сч7C3 and Сч23С6).) are even less resistant to coagulation. Heat-resistant die steels, complex-alloyed with chromium, molybdenum, tungsten, vanadium, are prone to secondary hardening during tempering. The maximum hardening (peak of secondary hardening) is achieved after tempering at 500 - 550 0С. A higher tempering temperature leads to softening. The hardness increases most intensively during secondary hardening with an increase in the content of carbon, chromium and silicon in the steel. In addition to the formation of special carbides of the M7C3 and M23C6 types, chromium dissolves in ferrite, increasing the strength, and dissolves in carbide phases of the M6C, MС and M2C types, contributing to a more complete dissolution of special austenite carbides when heated for quenching. The thermal background, the initial structure of the steel, strongly affects the properties after the final heat treatment. The most pronounced influence of thermal previous history affects the phenomenon of structural inheritance. Structural inheritance is expressed in the restoration of the original grain in shape and orientation after phase recrystallization. Numerous studies in the field of structural inheritance have been conducted by acad. Sadovsky V.D. with others. In particular, it was found that the formation of a fine structure during final heat treatment occurs under the conditions of inheritance of elements of the initial submicrostructure [2]. In many cases, in order to improve the service properties of finished products, pre-heat treatment is carried out, i.e., an optimal thermal background is created. These methods include all modes of heat treatment with multiple phase recrystallization [3]. Such heat treatment includes the first phase recrystallization with heating to extreme temperatures, accelerated cooling, the second phase recrystallization with heating to the temperatures usually accepted for this steel, quenching and final tempering. The essence of the method of heat treatment with double phase recrystallization by the optimal mode is to create the necessary thermal prehistory of steel. During the first phase recrystallization, heating is carried out to extreme temperatures of 1100 0C for carbon and low-alloy steels. After accelerated cooling from these temperatures, a structure with the maximum level of defect of the crystal structure is formed [4]. At high-temperature heating, the dissociation of refractory nitride, carbonitride and oxygen-containing phases occurs and their transition to a solid solution. This process is intensive in the area of heating temperatures of 1100 0C. The beginning of the dissolution of these phases is characterized by the chemical micro-uniformity of the solid solution. In this case, during cooling, during the γ-α transformation, a structure with an increased level of defect in the crystal structure is formed [5]. Previous quenching temperature 0C FIGURE 1. Change in the grating period of steel 5ХНМ depending on the previous quenching temperature of the intermediate tempering There is the creation of «zone» structures, the fragmentation of coherent scattering regions (CSR) and the growth of micro-distortions of the crystal lattice [6]. A further increase in temperature in the region beyond the extreme temperatures leads to the homogenization of austenite. After cooling and γ-α transformation, the defect of the α – phase lattice is obtained lower. During the quenching process, the carbon atoms switch to dislocations, and the tetrogonality of the martensite lattice decreases (Fig. 1). RESULTS AND DISCUSSION The high heating temperatures used during the first phase recrystallization contribute to the dissolution of almost all the excess phases, but lead to a sharp increase in the austenitic grain. With accelerated cooling, a supersaturated solid solution is fixed during quenching. During intermediate tempering, not only carbide release occurs, but also the release of refractory impurity phases in the form of dispersed particles (nitrides, carbon nitride, oxides). During normalization, the release of these particles occurs without intermediate release [7]. Repeated phase recrystallization carried out from the heating temperature of Ac1 + 30 – 50 0C or Ac3 + 30 – 50 0 C takes place under the conditions of strong influence of the initial micro and sub microstructure. Dispersed particles of refractory admixture phases are both ready-made crystallization centers and barriers to the growth of austenitic grains [5]. Previous quenching temperature 0C FIGURE 2. Change in the amount of residual austenite (% γ phase) and the content of the amount of carbon in the residual austenite (%C in the γ phase) 5ХНМ steel, depending on the temperature of previous quenching and intermediate tempering. Therefore, after the second phase recrystallization, a redistribution of the amount of residual austenite and the content of the amount of carbon in the residual austenite is formed (Fig. 2). Previous quenching temperature 0C FIGURE 3. Mechanical properties of 5ХНМ steel depending on the previous quenching temperature and intermediate tempering In addition, the increased dislocation density formed during the first phase recrystallization with heating to extreme temperatures is inherited during the new α-γ-α transformation. METHODS This inheritance is accompanied, however, by a significant increase in the density of dislocations in the α - phase. According to the data of [6], the initial dislocations in austenite play an important role in the martensitic transformation [8]. Their specific constructions can serve as places of preferential origin of martensitic crystals. Such significant structural differences after heat treatment with double phase recrystallization were carried out in comparison with heat treatment using standard technology, which led to a noticeable increase in wear resistance during rolling friction with slipping, when sliding on hardened and loose abrasive, when sliding metal on metal (Fig.3) [9]. FIGURE 4. Wear become dependencies from temperature preliminary heating CONCLUSION It can be concluded that after the double phase recrystallization, the lattice period and the value of the austenitic grain takes a minimum value if the preliminary quenching was carried out with 11500C and the intermediate tempering was 550 0C [10]. Heat treatment of alloy steels carried out under extreme conditions increases the static strength (within the flow ability) from 11% to 20% (Fig.4). Analysis of experimental data on the thermos physical properties of substances at high temperatures allows, in principle, to establish the basic mechanisms of heat transfer and dissipation under these conditions not only in pure metals, but also in these alloys, and also to test the applicability of theoretical concepts currently accepted for transition metals. REFERENCES 1. 2. 3. Y.M. Kalinin, V.D. Sadovsky. Structural heredity in cemented alloy steels. MiTOM. 1966. No. 2. p. 7 -11. A.A. Mukhamedov. Investigation of properties after recrystallization of steel. MiTOM. 1972. No. 12. p. 14-20. T.M. Pugacheva, M.S. Kenis, B.F. Trachtenberg. Improving the efficiency of cold-shrink matrices by thermocyclic processing. In the book. : Thermocyclic treatment of metal materials. l. 1980. p. 70 – 71. 4. Yu.O. Mezhennyi, Yu.A. Skakov, R.S. Yaroslavtseva. Some structural transformations in the Fe – 24% alloy associated with the release of nitrogen from a solid solution. In: Interaction between dislocations and atoms of impurities in metals and alloys. Tula. TPI. 1969. p. 211-215. 5. Ya. Rakhimov, Z. Abdukakhkhorov, Structured conversion become under different type of the termal processing. “International Conference on Advance Research in Humanities Sciences and Education - 2022” online from New York, USA on Februare 28 th 2022 6. YA.Rahimov, Z.Abduқahkhorov. Vosstanovlenie detalej tipa valov naplavleniem iznosostojkimi materialami.//Jurnal “Ustojchivoe razvitie nauki i obrazovaniya”. g.Voronezh. № 12, 2017. P.208. 7. A Burxanov, Z. Abdukakhkhorov, Methods of increasing mechanical characteristic details of the technological machines, “International Conference on Advance Research in Humanities Sciences and Education - 2022” online from Florida, USA on Februare 22 th 2022 8. Sh.ImomqulovZ. Abdukakhkhorov, Improvement profile of the teeth dzhinnoy saws, “International Conference on Advance Research in Humanities Sciences and Education - 2022” online from Chikago, USA on Februare 24 th 2022 9. Ya.Rakhimov, Z.Abdukakhkhorov, The influence of heat treatment with repeated heating on the properties of materials of working mechanisms of agricultural machines, Sustainable development of science and education. Scientific and practical journal 2022. No. 2 10. Ya.Rakhimov, Z.Abdukakhkhorov, the impact of thermal processing tarikh on mechanical Hoss of metals, FerPIscientific technique journal, 2022. №4. 51- 55