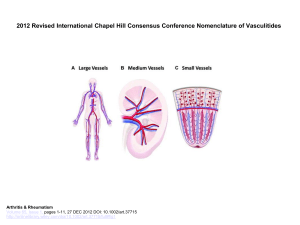

Fuel 324 (2022) 124525 Contents lists available at ScienceDirect Fuel journal homepage: www.elsevier.com/locate/fuel Full Length Article In-depth characterization of light, medium and heavy oil asphaltenes as well as asphaltenes subfractions Marziyeh Salehzadeh a, b, Maen M. Husein b, *, Cyrus Ghotbi a, *, Bahram Dabir c, Vahid Taghikhani a, d a Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, Iran Department of Chemical & Petroleum Engineering, University of Calgary, Calgary, Canada Department of Chemical Engineering, Amirkabir University of Technology, Tehran, Iran d Department of Chemical and Biomolecular Engineering, Rice University, Houston, USA b c A R T I C L E I N F O A B S T R A C T Keywords: Asphaltenes Fractionation Spectroscopic technique Elemental analysis Solubility Association Asphaltenes, and their related issues, have been the focus of many literature investigations. However, in-depth analysis of asphaltenes structure and its relation to asphaltenes stability has been considered by fewer studies. In this research, extensive analysis of the structure of asphaltenes extracted from light, medium, and heavy oils is provided, together with analysis of three subfractions of the medium oil asphaltene having the least, interme­ diate, and highest solubilities. To this end, elemental analysis, EDX, mass spectroscopy, FTIR, NMR, XRD, and SEM results were collected. Higher hydrogen content and hydrogen/carbon atomic ratio, lower aromatic nature and olefinic entities were observed in heavy oil asphaltenes as well as the most soluble subfraction. Moreover, the molecular structure of heavy oil asphaltenes and the most soluble subfraction displayed broader mass to charge (m/z) distribution range, longer alkyl side chains as well as higher number of stacked aromatic sheets within their nanoclusters. Asphaltenes hydrogens in α position followed similar trend as their heteroatom con­ tent, which was higher for the less soluble subfraction and medium oil asphaltenes. Generally, heavy oil asphaltenes possessed a molecular structure that was closer to the most soluble asphaltenes subfraction, whereas light oil asphaltenes possessed a molecular structure similar to the least soluble subfraction. Asphaltenes pre­ cipitation/destabilization was attributed to primarily higher attractive π-π interactions coupled with lower steric hindrance. 1. Introduction Asphaltenes are the most polar and complex components of crude oil [1,2]. While soluble in aromatic solvents, asphaltenes tend to precipitate with the addition of different types/amounts of n-alkanes to crude oil. Such solubility attributes follow from the highly polydisperse nature of asphaltenes molecules [3]. Over the past decades, a tremendous effort had been invested to characterize, analyze, and determine the properties Abbreviations: A3000-2750, C–H stretching area of aliphatic; A3150-3000, C–H stretching area of aromatic; APCI, Atmospheric pressure chemical ionization; C aliphatic, Aliphatic carbon; C aromatic, Aromatic carbon; CA-Caliph, Substituted aromatic carbons; CAH, Aromatic carbon atoms bonded to hydrogen atoms; CAHβX, Aromatic carbons bonded to β hydrogens to heteroatom; CAP3, External peripheral aromatic carbon atoms at the junction of two fused rings; Cau, Carbons number per aromatic unit; CAX, Aromatic carbons attached to heteroatoms; CDCl3, Deutero-chloroform; CHNS, Carbon-hydrogen–nitrogen-sulfur; CY, Internal triple bridgehead aromatic carbons; dm, Distance between two aromatic sheets; dr, Distance between saturate chains; EDX, Energy-dispersive X-ray spectroscopy; F1, Least soluble subfraction; F2, Intermediately soluble subfraction; F3, Most soluble subfraction; fa, Aromaticity; FTIR, Fourier transform infrared; GPC, Gel permeation chromatography; H, Heavy crude oil; Hal, Aliphatic hydrogen; Halα, Aliphatic hydrogen in α-position; Halβ, Aliphatic hydrogen in β-position; Halγ, Aliphatic hydrogen in γ-position; Har, Aromatic hydrogen; Hol, Hydrogen attached to olefinic carbon; I1376, CCH2/C-CH3 symmetric bending; I14555, C-CH2/C-CH3 asymmetric bending; I1600, Aromatic C=C stretching; I2924, Aliphatic CH2 stretching asymmetric; I2957, Aliphatic CH3 stretching asymmetric; I3050, Aromatic C–H stretching; IAr, Hydrogen aromaticity index; L, Light crude oil; La, Average diameter of aromatic sheets; Lc, Average height of aromatic cluster perpendicular to plane of sheets; M, Medium crude oil; m/z, Mass to charge; Me, Number of aromatic sheets in a cluster; MS, Mass sectrometry; MW, Molecular weight; NMR, Nuclear magnetic resonance; PAH, Polycyclic aromatic hydrocarbon; Ra, Number of aromatic rings for each aromatic sheet; SEC, Size exclusion chromatography; SEM, Scanning electron microscopy; VPO, Vapor pressure osmometry; XPS, X-ray photoelectron spectroscopy; XRD, X-ray diffraction. * Corresponding authors. E-mail addresses: mhusein@ucalgary.ca (M.M. Husein), ghotbi@sharif.edu (C. Ghotbi). https://doi.org/10.1016/j.fuel.2022.124525 Received 13 March 2022; Received in revised form 25 April 2022; Accepted 4 May 2022 Available online 10 May 2022 0016-2361/Crown Copyright © 2022 Published by Elsevier Ltd. All rights reserved. M. Salehzadeh et al. Fuel 324 (2022) 124525 of asphaltenes molecules with the aid of various techniques [4-12]. Nevertheless, these studies have been challenged by the complexity of asphaltenes molecules, their source- and extraction proceduredependent properties, presence of impurities and asphaltenes selfaggregation [13]. Asphaltenes precipitation and deposition upstream and downstream of oil industry decreases well productivity, alters rock wettability, re­ stricts/clogs production facilities and flow lines, stabilizes emulsions, and fouls catalysts and equipment [1,14,15]. On the other hand, the recent success of functional carbon materials derived from asphaltenes in gas adsorption [16], electrodes manufacturing [17-19], water puri­ fication, and other fields [20] depicts a bright potential for asphaltenes applications. Subsequently, elucidating the chemical structure of asphaltenes molecules and its role in asphaltenes surface activity, pre­ cipitation and deposition is crucial to prescribing effective remedies and maximizing the beneficial use of asphaltenes. Fractionation is commonly practiced for enhancing asphaltenes characterization. By splitting the asphaltenes fraction into subfractions, the complexity of the sample is reduced, resulting in higher resolution, rather than relying on broad average values. Considerable research has been conducted on asphaltene fractionation using various approaches, including binary solvent mixtures that differ in solvent type, tempera­ ture, contact time and sample/solvent ratio [6,21-31]. A linear relationship between the amount of precipitated asphaltenes and toluene/n-heptane volumetric ratio was reported by Trejo et al. [28], which was at odds with the findings of Tojima et al. [24]. Another investigation on toluene/n-heptane binary solvent showed that the most highly condensed polynuclear aromatics were detected in the lowest soluble asphaltenes subfraction [24]. Asphaltenes fractionation using a binary solvent of tetrahydrofuran/n-hexane showed that the subfraction more responsible for the high viscosity of heavy oils displayed a lower H/C ratio and a higher content of metals, aromaticity, heteroatoms, and condensed aromatic rings [22]. Asphaltenes fractionation using a binary solvent of methylene chloride/pentane suggested that the highest po­ larity subfraction contains more metals and dissolves slower than the lowest polarity subfraction [27]. Moreover, using two n-pentane/crude oil (v/v) ratios showed that the higher volume ratio corresponded to more interfacially active asphaltenes which displayed smaller aggregate sizes and more branched aliphatic side chains with a higher content of hydroxylic and carboxylic groups [6,32]. The analytical techniques utilized to characterize asphaltenes have been mostly defined by the analysis objective, which was mostly focused on chemical structure and elemental analysis [1]. Various techniques such as mass spectrometry (MS), size exclusion chromatography (SEC), nuclear magnetic resonance (NMR), Fourier transform infrared (FT-IR), X-ray photoelectron spectroscopy (XPS), Raman spectroscopy, X-ray diffraction (XRD), and many others have all been used separately, or in tandem, for this purpose [9,11,20,33]. Spectroscopic techniques are powerful tools to characterize complex compounds. In particular, NMR spectroscopy has been successful in demonstrating a variety of structural motifs within asphaltenes molecules, such as the average number of aromatic rings and the alkyl chain lengths of an average molecule [4,7,10,22,34-39]. Nevertheless, the average parameters obtained from NMR, elemental analysis and MW results are controversial, since they do not capture the molecular distribution and might not accurately reflect the true chemical nature of asphaltenes [40]. A review of the asphaltenes characterization literature reveals that, despite the large volume of investigations, no studies have considered detailed characterization of asphaltenes derived from crude oils with appreciable difference in API gravity. In the current work, asphaltenes extracted from light, medium and heavy oils were subjected to detailed characterization, including elemental analysis, energy-dispersive X-ray spectroscopy (EDX), MS, FTIR NMR, XRD and scanning electron mi­ croscopy (SEM). These measurements were used to explore asphaltenes MW distribution, functional groups, aromaticity and carbon and hydrogen distribution in the molecular structure, nanocluster features (including the distance between two aromatic sheets/aliphatic chains and the average number of aromatic sheets in a molecule and their size) as well as the morphology of asphaltenes aggregates. Previously, these techniques were used separately [8,9,36,41] or in a limited number of combinations [4,6,11,42]. In addition to the origin of the asphaltenes, the asphaltenes of the medium crude were fractionated into least, intermediately and most soluble subfractions and subjected to the same analyses. This characterization was used to correlate asphaltene char­ acteristics to their solubility. More accurate information, e.g. MW dis­ tribution, is expected when comparing properties of asphaltenes subfractions to those of their parent asphaltenes or different origin asphaltenes. Unlike some literature reports [6,40], procedures to more carefully isolate asphaltenes subfractions have been developed in this study. We believe that the structural differences of asphaltenes from diverse crude oil sources as well as solubility-based subfractions provide deeper insight on asphaltenes properties. This in-depth understanding of structural differences is required to comprehend and predict the mech­ anisms of asphaltenes precipitation/destabilization behavior on a large scale. 2. Experimental procedure 2.1. Materials and methods Asphaltenes were extracted from two crude oil samples (light and medium) from south west of Iran as well as Athabasca bitumen (Canada) using ASTM standard methodology D6560-12 with slight variation [4345]. Briefly, 40-fold n-heptane (≥99%, Macron, Canada) was added to the oil sample and the mixture was refluxed for 1 h. Then, the mixture was kept in a dark place for 24 h. The precipitated asphaltenes were filtered using a 2.5 μm filter paper (Whatman grade 42). The filter paper containing precipitated asphaltenes was placed in a Soxhlet and refluxed in n-heptane to remove the maltenes from the precipitate. Reflux continued until the n-heptane was clear. Asphaltenes were then extracted from the filter with refluxing toluene (99.5%, VWR, Canada). The toluene was left to evaporate and the asphaltenes were left to dry at room temperature. The API gravity and the asphaltenes content of the light crude oil (L) were 32 and 0.5 wt%, respectively, whereas the API gravity and asphaltenes content of the medium crude oil (M) were 26.9 and 5.5%. The bitumen sample (designated as H, for heavy) had an API gravity of 9.6 and included 11 wt% asphaltenes. The asphaltenes obtained from the medium crude oil (M) were fractionated into three subfractions using a procedure described in Fig. 1. The medium crude oil asphaltenes were designated as parent asphaltenes with respect to their subfractions. To fractionate the parent asphaltenes, 1 g of the asphaltenes was dissolved in 67 mL toluene and stirred for 24 h before being centrifuged for 20 min at 12000 rpm to remove potential contaminants. The first subfraction, F1, was prepared by adding n-heptane to the asphaltenes solution in toluene to make a 50/ 50 (v/v) n-heptane/toluene volume ratio. F1 subfraction was precipi­ tated upon stirring the mixture for 24 h and centrifuging for 20 min at 12000 rpm. The second subfraction, F2, was precipitated by adding nheptane to the centrifuged 50/50 (v/v) n-heptane/toluene mixture to achieve a 75/25 (v/v) n-heptane/toluene mixture, then centrifuging the resultant mixture for 20 min at 12000 rpm. The asphaltenes remaining in the 75/25n-heptane/toluene mixture were designated as F3 sub­ fraction, and were subsequently recovered by evaporating the n-hep­ tane/toluene solvent at room temperature. The mass proportions of subfractions F1, F2, and F3 were 53.4 wt%, 31.3 wt%, and 13.7 wt% of parent the asphaltene, respectively. Various analyses were performed on the asphaltenes samples in order to provide detailed description of the different molecular struc­ tures of the asphaltenes. The elemental composition of asphaltenes L, M and H as well as the M asphaltenes subfractions was identified using Elementar UNICUBE (Langenselbold, Germany). Elemental analysis measured the carbon-hydrogen–nitrogen-sulfur (CHNS) content of each 2 M. Salehzadeh et al. Fuel 324 (2022) 124525 Fig. 1. Schematic representation of medium crude oil asphaltenes fractionation procedure. asphaltenes. The oxygen content was calculated by subtracting the weight percentage of CHNS from 100%. Scanning electron microscope (SEM) photographs coupled with energy-dispersive X-ray spectroscopy (EDX) (Phenom Pro X, Phenom-World BV, Netherlands) were collected to further characterize the structure and elemental composition (except for hydrogen content [46]) of the asphaltenes samples. To determine the asphaltenes functional groups and structural pa­ rameters, an Agilent Cary 630 Fourier-transform infrared (FTIR) spec­ trometer (Agilent, Santa Clara, CA, USA) was used, which does not require any sample preparation for FTIR measurements and does not require the addition of materials such as KBr. In order to ensure repre­ sentative samples, our asphaltenes samples were thoroughly homoge­ nized prior to FTIR measurements. Each sample was scanned 128 times with wavelength ranging from 4000 to 400 cm− 1 with a 4 cm− 1 resolution. In order to unveil the structural characteristics of asphaltenes ag­ gregates, the X–ray fingerprints of the different asphaltenes were recorded. Rigaku Ultima III X-ray diffractometer (Rigaku Co. Ltd., Tokyo, Japan) with Cu Kα radiation operating at 40 kV and 44 mA was used. The samples were loaded in a Rigaku zero background sample holder model 906,163 (10 mm × 0.2 mm Well Si510) and the scans were ◦ ◦ ◦ taken in the range of 2θ between 3 to 90 degrees with a 0.05 step and counting time of 1.0 degrees per min. Additionally, mass spectroscopy of the asphaltenes was recorded on Agilent Q-TOF 6520 ESI (Agilent Technologies, Santa Clara, CA, USA) and positive ionization. Asphaltenes were dissolved in toluene, then introduced to the atmospheric pressure chemical ionization (APCI) source via direct infusion while fragmentor voltage was set to 80 V and APCI source was set at 200 ◦ C. Nuclear magnetic resonance (NMR) spectra, a strong tool for exam­ ining the chemical nature of asphaltenes and their fragments [7], were acquired using a 600 MHz Bruker NMR with a broad band probe, operating at 150 MHz for 13C and 600 MHz for 1H. In each experiment, samples were prepared by dissolving 20 mg of asphaltenes in 1 mL of deutero-chloroform (CDCl3) in 5-mm tubes. The C-NMR were carried out with 15,000 scans, a sweep width of 36000 Hz, flip angle of 90◦ , 3 s for relaxation delay, acquisition time of 0.36 s, udeft as a pulse program and Waltz-16 as a decoupling program. The H-NMR spectra were the result of 100 scans, a flip angle of 30◦ , a relaxation delay of 1.0 s, an acquisition time of 3.4 s and sweep width of 9600 Hz. 3. Results 3.1. Elemental analysis Table 1 shows the CHNS content of the L, M and H asphaltenes as well as the subfractions of the parent M asphaltenes, including F1, F2 and F3. Between the L and H asphaltenes, the H/C atomic ratio increased from 0.97 to 1.22, suggesting significant changes in the molecular structure and a more aromatic character of L asphaltenes. Although the issue of asphaltenes deposition and well obstruction is more severe in light oil fields than in medium oil fields, the elemental analysis of L and M asphaltenes is not significantly different, except for the carbon and oxygen content. When comparing M asphaltenes subfractions, the elemental analysis in Table 1 shows that F1, i.e. least soluble, has the highest heteroatoms (N + S + O) content of 11.13 wt% and the heteroatoms content decreased to 9.32 wt% for the most soluble, F3, subfraction. Moreover, the hydrogen content and H/C atomic ratio are higher for the most soluble subfractions, F3, whereas the N and S content is lower. The O content is highest for F3 subfraction, without a specific trend. EDX analysis was also used to provide elemental analysis (excluding hydrogen) of the asphaltenes. Literature investigations suggest that CHNS elemental analysis results are more reliable than EDX results within the reported range [42], despite the fact that EDX provides in­ formation on more elements, including metals [33,42,47]. It is noted that EDX is a surface technique, where the electron beam allows char­ acterizing the first micrometers of the surface depth [48,49]. Table S1 reveals that C, O, N, and S are the most abundant elements, with trace amounts of Ni, V, Ti, Fe, Na, Mg, Ca, Si, Cl, and Al in most of the asphaltenes samples. Table 1 Elemental composition (wt%) and H/C atomic ratio of L, M and H asphaltenes as well as M asphaltenes subfractions, including F1, F2 and F3. C H N S O* Heteroatoms H/C * 3 L M H M (Parent Asphaltene) F1 F2 F3 83.40 6.80 1.20 7.22 1.40 9.81 0.97 81.95 6.88 1.17 7.16 2.85 11.17 1.00 81.32 8.31 1.26 8.15 0.98 10.38 1.22 82.03 6.85 1.23 7.44 2.47 11.13 0.99 82.19 7.43 1.19 6.89 2.31 10.38 1.08 81.89 8.80 0.92 5.20 3.21 9.32 1.28 Calculated in Section 2.1. M. Salehzadeh et al. Fuel 324 (2022) 124525 While elemental composition of asphaltenes is key to describing the asphaltenes molecular structure, more analyses are needed to properly describe the structure. The most informative and abundant part for each sample is displayed in Fig. 2. Asphaltenes L, M, and H all have distinct mass to charge (m/z) distribution, with the highest intensity peaks at m/z = 207.1, 391.26, and 198.1, respectively. The m/z distribution for asphaltenes L is nar­ rower when compared with asphaltenes M and H, while asphaltenes H shows a notable peak at m/z = 922. The distribution of relative abundance peaks of M asphaltenes sub­ fractions varied, with common most abundance peak at m/z = 391.26. Among the different subfractions, the most soluble subfraction, F3, revealed broader distribution, from m/z = 108 to 1325.9 with signifi­ cant relative abundance, while the number of intense peaks for sub­ fractions F2 and F1 dropped as well as their spectrum spanning. Moreover, in subfraction F2, the abundance of m/z = 666.4 is very sig­ nificant, while this peak displays almost the same intensity with m/z = 279.1 in subfraction F1. The average MW of asphaltenes from APCI mass spectroscopy were obtained using equation (E1) [41]. The average was derived by taking into account all peaks up to m/z ~ 1330, since there was no noticeable peak beyond this one. The outcome of MW calculation is included in Table 2. 3.2. Mass spectroscopy Investigating MW distribution for each asphaltenes provides valu­ able data, particularly in combination with the acquired relative weight/atomic ratios of various elements in the asphaltenes structure. Asphaltenes MW measurements are most often performed using vapor pressure osmometry (VPO), size exclusion chromatography (SEC) and mass spectrometry (MS) [50]. The MW obtained by VPO are in the range of several thousand amu [51], whereas those derived from SEC (or gel permeation chromatography (GPC)) yield values in the neighborhood of 10,000 amu [51]. Nevertheless, aggregation of asphaltenes molecules is problematic and may impact measurements obtained from VPO [50]. On the other hand, GPC measurements suffer from the possibility of exceeding asphaltenes critical micelle concentration and the uncertainty in determining asphaltenes MW, which are based on comparing with known standards [51]. MS analysis of asphaltenes MW has also proven to be challenging [41]. For example, the abundance of low MW fractions tends to conceal the less abundant higher MW fractions [52]. Although ionization techniques do not fully unfold the complex nature of mole­ cules such as asphaltenes, APCI has been reported as one of the more suitable ionization methods, since it displays less ionization bias and is capable to access wide range of classes of compounds and carbon number distribution [12,41]. The mass spectra for L, M and H asphaltenes as well as M asphaltenes subfractions are shown in Fig. 2. The m/z detection range was 100–3165, and the acquired abundance intensity was in the order of 107 for asphaltenes M and its subfractions, and 105 for asphaltenes L and H. Table 2 Average molecular weight determined for L, M and H asphaltenes as well as M asphaltenes subfractions, including F1, F2 and F3. L MW Avg Mw 302.4 M 409.5 H 376.3 M (Parent Asphaltene) F1 F2 F3 404.3 477.3 485.9 Fig. 2. Mass spectroscopy of asphaltenes (a) L; (b) M; and (c) H as well as M asphaltenes subfractions (d) F1; (e) F2; and (f) F3. 4 M. Salehzadeh et al. Fuel 324 (2022) 124525 ∑ (m) *area(allpeaks) z MW = ∑ area(allpeaks) 3.3. FTIR (E1) FTIR spectra for L, M and H asphaltenes as well as asphaltenes M subfractions F1, F2 and F3 are shown in Fig. 3. The raw results of the samples are collected under the same conditions without linear slope and offset baseline. The interpretation and calculations were performed without any baseline correction or smoothing, which in turn may in­ fluence the results. The FTIR spectra were normalized based on the C–H stretching of CH2 group. The areas of certain regions under the curve and the absorbance at specific wavenumbers were determined using OMNIC software. Table 3 lists the FTIR results reported based on ratios of integrated areas and/or intensities within a single spectrum. The ratio of the area under the FTIR curve of C − H stretching mode for the aliphatic (3000–2750 cm− 1) and the aromatic (3150–3000 cm− 1) groups is calculated and denoted as (A3000− 2750 /A3150− 3000 ) [53] in Table 3. H and F3 asphaltenes show the highest ratios of aliphatic to aromatic structures among the different asphaltenes and asphaltenes M subfractions. The ratio A3000− 2750 /A3150− 3000 reveals ~ 2 times increase between asphaltenes L and H, and a ~ 4 time increase between asphaltenes subfractions F1 and F3. Accordingly, light oil asphaltenes are The average MW increased with increasing subfraction solubility and the MW of the parent medium crude oil asphaltenes is within the range of its subfractions. In addition, M asphaltenes showed higher value of MW among the different origin asphaltenes, whereas L asphaltenes had the lowest MW. The elemental analysis and MW distribution are crucial to under­ standing asphaltenes molecular structure. These characterization tech­ niques, however, do not provide detailed information on the distribution of different elements within the structure of asphaltenes, including the number of carbon atoms in the polycyclic aromatic hydrocarbon (PAH) part versus the aliphatic part. Moreover, elemental analysis and MW distribution do not provide precise analysis of the different functional groups on asphaltenes molecules. FTIR, H-NMR, and C-NMR analyses have been carried out in an attempt to unveil this information. Fig. 3. FTIR results of (a) asphaltenes L, M and H; (b) subfractions of asphaltenes M, including F1, F2 and F3. 5 M. Salehzadeh et al. Fuel 324 (2022) 124525 more aromatic than heavy oil asphaltenes, and the least soluble asphaltenes subfractions are more aromatic. Two other parameters for assessing asphaltenes aromaticity can be extracted from the FTIR spectra, the hydrogen aromaticity index (IAr = I3050 / (I3050 + I2924)) [54] and the intensity ratio between the C = C aromatic stretch and the aliphatic CH2 stretching (I1600 / I2924) [6]. Higher values of IAr and I1600 / I2924 suggest more aromatic structure in the asphaltene molecule. Table 3 shows that IAr and I1600 / I2924 are higher for asphaltenes L and subfraction F1. In addition, the condensation degree, which is propor­ tional to the ratio of aromatic C–H stretching to aromatic C = C in­ tensities (I3050 / I1600) [11], suggests greater extent of condensation in L asphaltenes and the least soluble, F1, subfraction. The intensity ratios of CH2 to CH3 stretching asymmetric modes (I2924 / I2957) [6,55] and CH2/CH3 asymmetric to symmetric bending modes (I14555 / I1376) [53] can be used to determine differences in the aliphatic part of the asphaltenes molecules. Table 3 shows that Table 3 Relative parameters applied for comparing the aromatic and aliphatic parts of the asphaltenes L, M and H and sub-fractions of asphaltenes M. A3000− 2750 A3150− 3000 IAr I1600 I2924 I3050 I1600 nCH2 mCH3 I1455 I1376 L M H M (Parent Asphaltene) 12.079 13.855 23.67 0.403 0.846 0.398 0.839 0.289 0.59 0.389 0.837 0.338 0.699 0.196 0.449 0.798 0.787 0.686 0.76 0.731 0.543 1.234 1.256 1.51 1.299 1.411 1.64 1.015 1.002 1.1 1.013 1.026 1.102 F1 F2 F3 12.72 22.2 46.381 Fig. 4. H-NMR results of (a) asphaltenes L and H; (b) asphaltenes M and its subfractions, including F1, F2 and F3. 6 M. Salehzadeh et al. Fuel 324 (2022) 124525 asphaltenes H and subfraction F3 display higher CH2/CH3 ratios, sug­ gesting that there is more CH2 in the aliphatic part, implying longer alkyl side chains in their molecular structure. Despite the fact that H and F3 asphaltenes showed similarity in their molecular structures, including aromaticity and alkyl side chains, they display differences in some functional groups. The broad peak at 1030 cm− 1 is attributed to sulfoxides (S = O) [8], which is stronger for asphaltenes H, whereas this peak appeared weaker in subfraction F3, as shown in Fig. 3. Sulfoxide groups are highly polar and induce a variety of hydrogen bond interactions [56]. Such bonding was believed to provide strong building blocks for supramolecular structures in crystal engineering [57]. Sulfoxides are also considered as key factors in asphaltene adsorption at the oil–water interface, hence, W/O emulsion stability [56]. Another surface-active functional group, carbonyl groups recognizable at ~ 1700 cm− 1, appeared to be very significant in sub­ fraction F3, while asphaltenes H seems to have no peak in this region. 3.5. C-NMR C-NMR analysis is limited to M asphaltenes and their subfractions F1, F2 and F3, in order to maintain manageable volume of data and com­ putations. Fig. 5 depicts the C-NMR spectra of M asphaltenes and their subfractions, and Table 5 summarizes the results for defined chemical shifts. Various chemical shifts have been used in evaluating the C-NMR spectrum according to the literature [7,10,58,64]. However, owing to a lack of consensus, the most recently recommended chemical shift ranges [10,58,64,65] were evaluated, and the most relevant ones were picked based on the spectra of our asphaltenes samples. In line with the results of FTIR and H-NMR measurements, C-NMR spectrum shows an ascending trend in the aliphatic portion of the molecular structure of subfractions with higher solubility. Moreover, asphaltenes aromaticity reveal that the highest and lowest values of 0.58 and 0.31 correspond to F1 and F3 subfractions, respectively. In addition, asphaltenes M, as the parent asphaltenes, have an aromaticity of 0.4, which corresponds to approximately the average of the different subfractions. In general, as the subfractions become more soluble, the ratios of total CH3, branched CH3, terminal isobutyl CH3, and the naphthenic parts in asphaltenes molecular structures increase, whereas the ratio of terminal CH3 and CH3 bonded to PAH remain constant for all subfractions. In the chemical structure of the less soluble subfractions, the olefinic carbons and the substituted aromatic carbons (CA-Caliph) occupy larger portions. The ar­ omatic carbons attached to heteroatoms (CAX) and the aromatic carbons bonded to β hydrogens to heteroatom (CAHβX) reveal a similar trend. The ratio of aromatic carbons associated with heteroatoms decreases with increasing the solubility of the subfractions. This result is consistent with the heteroatom content from the CHNS test, which revealed lower het­ eroatom content for the more soluble asphaltenes subfractions. There is overlapping of chemical shifts in the aromatic carbon signals in the 120.07 – 130.95 ppm range. Within this overlap, three types of carbons exist: aromatic carbon atoms bonded to hydrogen atoms (CAH), internal triple bridgehead aromatic carbons (CY), and external periph­ eral aromatic carbon atoms at the junction of two fused rings (CAP3). Andrews et al. [38] and Ruiz-Morales et al. [64] used the quantitative distortionless enhancement by polarization transfer (DEPT) experiment to calculate the percentage of protonated aromatic carbon (CAH) in re­ gions where signals overlapped, then calculate CY and CAP3. In this study, CAH was determined using the H-NMR spectra. The aromatic part of the H-NMR spectrum was integrated to show the hydrogens attached to aromatic carbons. We assumed that the same number of carbons were associated with these hydrogens as CAH. Following the subtraction of protonated carbons from the total carbons in the region containing the sum of the three carbons CAH, CY and CAP3, 116.53 – 134.76 ppm, CY and CAP3 are calculated based on their integral percentage in this region. Elemental composition, m/z distribution and detailed molecular structure information of the asphaltenes provide profound insight into how asphaltenes structures differ within a given asphaltenes sample or different asphaltenes sources. The structure, size, and appearance of asphaltenes aggregates were further studied using XRD and SEM tech­ niques to describe asphaltenes structure at a different level. 3.4. H-NMR Fig. 4 depicts the H-NMR spectra of asphaltenes L and H. Significant differences in the chemical shift ranges in aliphatic (0.5 – 4.5 ppm) and aromatic (6.5 – 9 ppm) regions are observed between the two asphal­ tenes. The aliphatic part is attributed to γ, β and α positioned hydrogens with chemical shift ranges of 0.5 – 1 ppm, 1 – 1.9 ppm and 1.9 – 4.5 ppm, respectively [58,59]. The normalized integral results of asphaltenes derived from light, medium and heavy crude oils in these specified blocks are presented in Table 4. Although other authors [60] have used somewhat different chemical shifts, the general trend for the different asphaltene samples and medium asphaltene subfractions is the same for the chemical shifts utilized in this work. Table 4 suggests that asphal­ tenes L have more aromatic and less aliphatic components comparing with asphaltenes M and H. Although the relative value of γ positioned hydrogens is higher in asphaltenes L, the β positioned hydrogens in L asphaltenes are less than asphaltenes M and H. For further examination of the alkyl side chain length, data such as FTIR spectra are necessary. The FTIR results in Table 3 indicate a lower nCH2/mCH3 ratio for asphaltenes L, hence these asphaltenes have shorter alkyl side chains compared with asphaltenes M and H. It is worth noting that the trend in the α positioned hydrogens and that of the heteroatoms content match. According to Table 1 the lowest and highest values of α position hy­ drogens are related to asphaltenes L and M, which displayed 9.80 wt% and 11.17 wt% heteroatoms content, respectively. The olefinic entities (4.5 – 6.5 ppm) tend to decline for asphaltenes originating in heavier oils and clearly the asphaltenes structure become more aromatic for asphaltenes derived from lighter oils. The H-NMR spectra and normalized integral results in defined blocks for asphaltenes M and its subfractions are also presented in Fig. 4 and Table 4. The highest soluble subfraction, F3, contains more aliphatic hydrogens in γ and β positions and fewer α positioned hydrogens. Table 4 further shows that the less soluble subfraction, F1, contains more hydrogens at aromatic and olefinic positions than the more soluble subfractions. 3.6. XRD Table 4 H-NMR chemical shift ranges [58,59,61-63] and normalized integral results for (a) asphaltenes L, M and H; (b) subfractions of M asphaltenes, including F1, F2 and F3. Hal (0.5-4.5 ppm) Hal; γ (0.5-1 ppm) Hal; β (1-1.9 ppm) Hal; α (1.9-4.5 ppm) Hol (4.5-6.5 ppm) Har (6.5-9 ppm) L M H 0.76 0.32 0.39 0.04 0.03 0.21 0.83 0.23 0.44 0.16 0.03 0.15 0.89 0.27 0.49 0.12 0 0.11 The XRD pattern can provide information about the structure and size of asphaltenes nanoclusters [66]. The XRD fingerprints of the different asphaltenes and asphaltenes M subfractions are shown in Fig. 6. The XRD pattern of all asphaltenes shows three superimposed peaks: one at 2θ ~ 20◦ , which is the γ-band and is attributed to the aliphatic portion, another at 2θ ~ 25◦ , which is the 002-band and is attributed to the aromatic portion and a third peak at 2θ ~ 43◦ , which is the (10)-band and is attributed to the aromatic sheets of asphaltenes. The XRD patterns in the area under 2θ of 20◦ and 25◦ peaks clearly shows that asphaltenes L contain more aromatics than asphaltenes M, and asphaltenes H contains the least aromatics. Inspecting the same 2θ M (Parent Asphaltene) F1 F2 F3 0.83 0.18 0.41 0.23 0.05 0.12 0.84 0.17 0.46 0.21 0.04 0.12 0.89 0.33 0.48 0.07 0 0.11 7 M. Salehzadeh et al. Fuel 324 (2022) 124525 Fig. 5. C-NMR results of sub-fractions and parent asphaltenes. Table 5 C-NMR chemical shift ranges and normalized integral results for the parent M asphaltenes and their subfractions. C aliphatic (10–60 ppm) C aromatic (110.6–156.2 ppm) Terminal CH3 (10.5–17 ppm) Total methyl (10–21.8 ppm) Branched CH3 (17–21.8 ppm) CH3 bonded to PAH (21.3 ppm) Terminal isobutyl CH3; & possible CH2 α to t-CH3 (21.8–24 ppm) Naphthenic (24–40 ppm) Olefin (110.6–116.53 ppm) CAHβX (110.6–116.53 ppm) Cah (116.53–130.95 ppm) CY (120–127.78 ppm) CAp3 (127.78–134.76 ppm) CA-Caliph (134.7–139.41 ppm) CAX (139.41–156.2 ppm) M (Parent Asphaltene) F1 F2 F3 0.6 0.4 0.07 0.16 0.08 0.01 0.06 0.42 0.58 0.07 0.15 0.08 0.02 0.04 0.57 0.43 0.07 0.17 0.1 0.02 0.05 0.69 0.31 0.07 0.17 0.11 0.02 0.06 0.41 0.01 0 0.27 0.18 0.11 0.05 0.02 0.3 0.04 0.03 0.23 0.15 0.11 0.07 0.17 0.43 0.01 0 0.26 0.19 0.11 0.06 0.04 0.45 0.01 0 0.18 0.11 0.1 0.04 0.04 lc = Cau = λ 2sinθγ (E1) dm = λ 2sinθ002 (E2) 1.84λ (E3) la = ωcosθ10 la + 1.23 0.65 (E4) (E5) Ra = la 2.667 (E6) Me = lc dm (E7) fa = A002 A002 + Aγ (E8) where λ is the wavelength of the applied radiation (Cu Kα), θ is the Bragg angle, ω is the full width of the peaks at half maximum and A is the area under the corresponding peak. Table 6 reveals that the average distance of two aromatic sheets (dm) of the studied asphaltenes are from 3.5 to 3.52 Å, which suggests almost the same distance between aromatic sheets of all asphaltenes samples. This range of dm is higher than of a pure graphite structure (dm = 3.4 Å) [42], which may be a result of steric hindrance imparted by circum­ ferential substituents of the asphaltenes aromatic sheets [67]. Notably a little higher dm values are obtained for asphaltenes H and the most soluble subfraction, F3. The distance between the saturates chains (dr) is higher than that of the aromatic sheets for all asphaltenes samples. Moreover, dr range for asphaltenes derived from light, medium and heavy oils varies from 4.63 to 4.75 Å, while in the subfractions of asphaltenes M it varied from 4.56 to 4.65 Å, which can be consider sufficiently close to each other. Table 6 shows tight ranges, from 10.06 to 11.31 and from 11.11 to 11.60 Å, for the average diameters of the aromatic sheets (La) of the different asphaltenes (L, M and H) and asphaltenes M subfractions, respectively. Asphaltenes H has smaller La, while asphaltenes M display the largest La. On the other hand, subfraction F1 displays the largest size of aromatic sheets, La. Lc values for asphaltenes L, M and H are 25.3, 27.1 and 33.12 Å, respectively, and for subfractions F1, F2 and F3 are 27.37, 27.62 and 38.07 Å, respectively. Furthermore, the number of stacked aromatic sheets in a nanocluster of asphaltenes increased from 8.23 in asphaltenes L to 10.4 for asphaltenes H. The same trend is observed in asphaltenes M subfractions with Me = 8.83 for F1, and Me = 11.85 for F3 subfraction. The trend of Lc and Me suggest that by increasing the H/C ratio or decreasing the aromaticity, the number of stacked aromatic sheets increased in asphaltenes nanoclusters. On the other hand, the average number of aromatic rings in the aromatic sheets for all asphaltenes is ~ 4, which falls within the range of the literature (4 to 10 fused rings) [68]. interval for asphaltenes M subfractions reveals that the aromaticity of the parent asphaltenes and their subfraction F1 is higher than sub­ fraction F2, while subfraction F3 displays the lowest aromaticity. When these data are compared to the H/C ratio of the asphaltenes in Table 1, it is concluded that a higher H/C ratio corresponds to a lower aromaticity. The structural parameters of the asphaltenes clusters that can be quantified through XRD patterns include dr (distance between saturate chains), dm (distance between two aromatic sheets), Lc (average height of aromatic cluster perpendicular to plane of sheets), La (average diameter of aromatic sheets), Cau (carbons number in the aromatic unit), Ra (number of aromatic rings for each aromatic sheet), M (number of aromatic sheets in a cluster) and fa (aromaticity) [9,42]. These param­ eters can be calculated using Equations (E1) - (E8) below [9,42]. The results are presented in Table 6. Additionally, Fig. 7 shows a schematic structure of a single asphaltenes nanocluster to provide better under­ standing of the different parameters. dr = 0.9λ ωcosθ002 8 M. Salehzadeh et al. Fuel 324 (2022) 124525 Fig. 6. X-ray diffraction pattern of (a) asphaltenes L, M and H; and (b) asphaltenes M subfractions, including F1, F2 and F3. However, this value does not indicate a major difference among the different asphaltenes. Also, the number of carbons per aromatic unit (Cau) obtained between 17.37 and 19.73 for all the asphaltenes. Lastly, the aromaticity (fa) calculated by XRD pattern is highest for asphaltenes L and subfraction F1 (0.14 and 0.12, respectively), whereas it is lowest for asphaltenes H and the most soluble subfraction F3 (0.02 and 0.04, respectively). In-depth molecular structure analysis of the asphaltenes coupled with asphaltenes nanocluster description assists in understanding and predicting a probable structure of various asphaltenes. The XRD results for some parameters such as Ra and fa follow the NMR trends. Never­ theless, parameters estimated through NMR would be more accurate and reliable when it comes to molecular scale. Although various parameters can influence the appearance and morphology of asphaltene samples, asphaltenes molecular structure could be another factor. Figure S1 shows SEM images of asphaltenes L, M, and H, as well as M asphaltenes subfractions F1, F2, and F3, which generally shows two types of smooth and porous surfaces. 4. Discussion From a thermodynamic perspective, asphaltenes solubilization/sta­ bilization versus precipitation/destabilization is an outcome of a bal­ ance among entropic diffusion interactions and intermolecular interactions among the asphaltenes molecules and the rest of the crude oil constituents as well as among the asphaltenes molecules themselves. Attractive intermolecular interactions among asphaltenes molecules and the rest of crude oil constituents, mostly notably resins [69,70], favor asphaltenes solubilization/stabilization, whereas attractive intermolec­ ular interactions among asphaltenes molecules favor precipitation/ destabilization. Nevertheless, some literature suggests that asphaltenes subfractions with less self-association tendency and lower polarity play a significant role in stabilizing the higher-polarity subfractions [71,72], in similar fashion to resins. Entropic diffusion interactions always act in 9 M. Salehzadeh et al. Fuel 324 (2022) 124525 aggregation has been established [71,75,78,79]. M asphaltenes con­ tained just few more stacked aromatic sheets in their nanocluster than L asphaltenes, which might be attributed to hydrogen bonding. The aromaticity of asphaltenes decreases monotonically from L to H asphaltenes, while the length of the pendant groups together with the fraction of hydrogens in the β position increase by 26.3 % and 25.6 %, respectively. Accordingly, one may interpret asphaltenes H stability by the diminishing role of π–π aromatic interaction and the growing role of steric hindrance. The higher number of stacked aromatic sheets of asphaltenes H in XRD results might be explained by a strong peak of sulfoxides in this asphaltenes sample, which can cause a variety of hydrogen bond interactions. M asphaltenes were fractionated by dissolving in toluene, then adding different amounts of n-heptane. Asphaltenes have a range of solubility parameters close to that of toluene, whereas the solubility parameter of n-heptane is lower than that of asphaltenes and toluene [80]. Addition of n-heptane to asphaltenes solution in toluene lowers the solvent solubility parameter, hence promotes asphaltenes precipitation. Among M asphaltenes subfractions, F1 portrayed the highest aroma­ ticity, the least branching and the shortest aliphatic chains, suggesting higher subfraction solubility parameter [81]. Using molecular dynamic simulation, literature findings showed that asphaltenes with short lateral chains are the quickest to precipitate, when n-heptane is added [78]. Subfraction F1 with the highest solubility parameter, displayed the highest aromaticity, heteroatoms content and shortest pendant groups. These features promote π–π and other van der Waals interactions, including Keesom, Debye and London, among asphaltenes molecules. Higher interaction coupled with low steric hindrance promotes asphal­ tenes association and precipitation. The least soluble subfractions have been reported to have a greater proclivity to aggregate and form deposits that are more difficult to remediate [72]. On the other hand, sub­ fractions with longer lateral chains have a stronger interaction with nheptane molecules, but also high steric hindrance, making them more stable. Lower aromaticity, longer pendant groups and more branching of the more stable subfraction F3 favor higher steric hindrance with less π–π interaction. While subfraction F3 was the most stable, its highest oxygen content and very significant peak of carbonyl groups, which promote hydrogen bonding, may explain the higher number of stacked aromatic sheets in this subfraction’s nanocluster. Literature reports suggest that asphaltenes fractions with less self-association tendency and lower po­ larity (similar to subfraction F3) play a significant role in reducing nanoaggregation and stabilizing the higher-polarity fractions (similar to subfraction F1) [71,72]. Accordingly, the presence of subfraction F3 may in fact improve the stability and reduces precipitation and deposition for the parent M asphaltenes. Fig. 7. Schematic structure of one asphaltenes nanocluster [42]. Table 6 Nanocluster structural analysis of asphaltenes L, M and H and asphaltenes M subfractions, including F1, F2 and F3, based on XRD patterns. dr dm La Lc Me Ra Cau fa L M H 4.75 3.5 11.02 25.3 8.23 4.13 18.85 0.14 4.63 3.51 11.31 27.1 8.73 4.24 19.3 0.11 4.68 3.52 10.06 33.12 10.4 3.77 17.37 0.02 M (Parent Asphaltene) F1 F2 F3 4.65 3.5 11.6 27.37 8.83 4.35 19.73 0.12 4.56 3.5 11.11 27.62 8.88 4.16 18.98 0.10 4.65 3.51 11.11 38.07 11.85 4.17 18.99 0.04 favor of asphaltenes solubilization/stabilization together with the repulsive steric hindrance among asphaltenes molecules. In this anal­ ysis, precipitation and aggregation are assumed to proceed hand in hand, away from any kinetic limitations. Literature investigations suggest that polyaromatic cores, polarity/ heteroatoms and pendant groups are key features governing the inter­ molecular interactions among asphaltenes molecules as well as other materials and surfaces [73,74]. The characterization results of this study show that L asphaltenes, i.e. the least stable asphaltenes, possess the largest aromatic cores with slightly higher metals and nitrogen content, lower overall content of heteroatoms and shorter aliphatic chains. These features suggest asphaltenes association majorly driven by attractive π–π interaction coupled with low steric hindrance. The contribution of attractive electrostatic, polar interactions [74,75] and hydrogenbonding are likely less influential. Notably, large aromatic cores in­ crease asphaltenes phobic forces toward the increasing alkane fraction in the mixture. Literature showed that asphaltenes originating from unstable oil fields generally display more aromaticity and polarity than stable ones [72,76]. While L asphaltenes are the most aromatic, they were not the most polar. M asphaltenes have higher polarity owing to their higher content of heteroatoms. These findings show that aroma­ ticity is more important parameter in asphaltenes association relative to polarity, which is consistent with the molecular dynamic studies of Sedghi et al. [75,77]. The main difference in heteroatoms content of L and M asphaltenes is related to oxygen, since their sulfur and nitrogen contents are nearly identical. Oxygen typically exists in functional groups such as phenolic, carboxylic, hydroxylic, and ketonic. The role of these functional groups in initiating hydrogen bonding and promoting 5. Conclusions In this study, the molecular structure of asphaltenes derived from light, medium and heavy crude oils was thoroughly investigated utiliz­ ing CHNS elemental analysis, EDX, MS, FTIR, NMR, XRD, and SEM techniques. Additionally, solubility-based subfractions from the medium crude oil asphaltenes were characterized. The hydrogen content and H/ C ratio were higher in the asphaltenes derived from heavy oil and the most soluble asphaltenes subfraction, these asphaltenes seem to have higher steric hindrance with less π–π interaction among their asphal­ tenes molecules. Elemental analysis showed high abundance of C, H, N, S and O with trance values of Ni, V, Ti, Fe, Na, Mg, Ca, Si, Cl, and Al. The mass spectroscopy revealed a broader m/z distribution for heavy oil asphaltenes and the most soluble asphaltenes subfraction. Moreover, while the m/z distribution of the subfractions differed, the most abun­ dant peak was the same for the parent asphaltenes and all its sub­ fractions. The FTIR, NMR, and XRD analyses corporated each other and confirmed the more aromatic nature of light oil asphaltenes and the least soluble asphaltenes subfraction. On the other hand, asphaltenes of heavier oils and the more soluble subfractions exhibited lower aromatic 10 M. Salehzadeh et al. Fuel 324 (2022) 124525 to aliphatic ratios and longer alkyl side chains. Less π–π interaction among these asphaltenes and higher steric hindrance promoted asphaltenes stability. Light oil asphaltenes possessed a molecular structure that was closer to the least soluble asphaltenes subfraction. On the other hand, heavy oil asphaltenes were more similar to the most soluble asphaltenes subfraction. Nevertheless, sulfoxide groups were abundant in heavy oil asphaltene, whereas carbonyl functional groups were abundant in the most soluble subfraction. These functional groups contribute in establishing hydrogen bonding. The olefinic entities fol­ lowed a similar trend to aromaticity. Furthermore, the α position hy­ drogens closely tracked the heteroatom content. The C-NMR test of asphaltenes subfractions revealed higher ratios of total CH3, branched CH3, terminal isobutyl CH3, and naphthenic parts in the more soluble asphaltenes subfractions. On the other hand, the less soluble sub­ fractions displayed larger portions of aromatic carbons that are substituted, attached to heteroatoms and bonded to hydrogen in β po­ sition to a heteroatom. These features along with higher aromaticity, heteroatoms content and shorter aliphatic chains promote π–π and other van der Waals interactions, including Keesom, Debye and London in the less soluble asphaltenes subfraction, while steric hindrance role decreased. [13] Zheng F, Shi Q, Vallverdu GS, Giusti P, Bouyssiere B. Fractionation and characterization of petroleum asphaltene: focus on metalopetroleomics. Processes 2020;8:1504. https://doi.org/10.3390/pr8111504. [14] Salehzadeh M, Akherati A, Ameli F, Dabir B. Experimental study of ultrasonic radiation on growth kinetic of asphaltene aggregation and deposition. Can J Chem Eng 2016;94:2202–9. https://doi.org/10.1002/cjce.22593. [15] Mahmoudi Alemi F, Mohammadi S, Mousavi Dehghani SA, Rashidi A, Hosseinpour N, Seif A. Experimental and DFT studies on the effect of carbon nanoparticles on asphaltene precipitation and aggregation phenomena. Chem Eng J 2021;422:130030. https://doi.org/10.1016/j.cej.2021.130030. [16] Tehrani NHMH, Alivand MS, Maklavany DM, Rashidi A, Samipoorgiri M, Seif A, et al. Novel asphaltene-derived nanoporous carbon with N-S-rich micromesoporous structure for superior gas adsorption: Experimental and DFT study. Chem Eng J 2019;358:1126–38. https://doi.org/10.1016/j.cej.2018.10.115. [17] Lee KS, Park M, Choi S, Kim J-D. Preparation and characterization of N, S-codoped activated carbon-derived asphaltene used as electrode material for an electric double layer capacitor. Colloids Surfaces A Physicochem Eng Asp 2017;529: 107–12. https://doi.org/10.1016/j.colsurfa.2017.05.052. [18] Qu W-H, Guo Y-B, Shen W-Z, Li W-C. Using asphaltene supermolecules derived from coal for the preparation of efficient carbon electrodes for supercapacitors. J Phys Chem C 2016;120:15105–13. https://doi.org/10.1021/acs.jpcc.6b05136. [19] Ni G, Qin F, Guo Z, Wang J, Shen W. Nitrogen-doped asphaltene-based porous carbon fibers as supercapacitor electrode material with high specific capacitance. Electrochim Acta 2020;330:135270. https://doi.org/10.1016/j. electacta.2019.135270. [20] Zuo P, Qu S, Shen W. Asphaltenes: Separations, structural analysis and applications. J Energy Chem 2019;34:186–207. https://doi.org/10.1016/j. jechem.2018.10.004. [21] Ovalles C, Rogel E, Moir M, Thomas L, Pradhan A. Characterization of heavy crude oils, their fractions, and hydrovisbroken products by the asphaltene solubility fraction method. Energy Fuels 2012;26:549–56. https://doi.org/10.1021/ ef201499f. [22] Kharrat AM. Characterization of Canadian heavy oils using sequential extraction Approach. Energy Fuels 2009;23:828–34. https://doi.org/10.1021/ef800743q. [23] Qiao P, Harbottle D, Tchoukov P, Masliyah J, Sjoblom J, Liu Q, et al. Fractionation of asphaltenes in understanding their role in petroleum emulsion stability and fouling. Energy Fuels 2017;31:3330–7. https://doi.org/10.1021/acs. energyfuels.6b02401. [24] Tojima M, Suhara S, Imamura M, Furuta A. Effect of heavy asphaltene on stability of residual oil. Catal Today 1998;43:347–51. https://doi.org/10.1016/S0920-5861 (98)00163-1. [25] Gutiérrez LB, Ranaudo MA, Méndez B, Acevedo S. Fractionation of asphaltene by complex formation with p -nitrophenol. A method for structural studies and stability of asphaltene colloids. Energy Fuels 2001;15:624–8. https://doi.org/ 10.1021/ef000180y. [26] Östlund J-A, Nydén M, Scott Fogler H, Holmberg K. Functional groups in fractionated asphaltenes and the adsorption of amphiphilic molecules. Colloids Surfaces A Physicochem Eng Asp 2004;234:95–102. https://doi.org/10.1016/j. colsurfa.2003.12.013. [27] Kaminski TJ, Fogler HS, Wolf N, Wattana P, Mairal A. Classification of asphaltenes via fractionation and the effect of heteroatom content on dissolution kinetics. Energy Fuels 2000;14:25–30. https://doi.org/10.1021/ef990111n. [28] Trejo F, Centeno G, Ancheyta J. Precipitation, fractionation and characterization of asphaltenes from heavy and light crude oils. Fuel 2004;83:2169–75. https://doi. org/10.1016/j.fuel.2004.06.008. [29] González G, Middea A. Peptization of asphaltene by various oil soluble amphiphiles. Colloids Surf 1991;52:207–17. https://doi.org/10.1016/0166-6622 (91)80015-G. [30] Subramanian S, Simon S, Gao B, Sjöblom J. Asphaltene fractionation based on adsorption onto calcium carbonate: Part 1. Characterization of sub-fractions and QCM-D measurements. Colloids Surfaces A Physicochem Eng Asp 2016;495: 136–48. https://doi.org/10.1016/j.colsurfa.2016.02.011. [31] Buenrostro-Gonzalez E, Andersen SI, Garcia-Martinez JA, Lira-Galeana C. Solubility/molecular structure relationships of asphaltenes in polar and nonpolar media. Energy Fuels 2002;16:732–41. https://doi.org/10.1021/ef0102317. [32] Fossen M, Kallevik H, Knudsen KD, Sjöblom J. Asphaltenes precipitated by a twostep precipitation procedure. 1. Interfacial tension and solvent properties. Energy Fuels 2007;21:1030–7. https://doi.org/10.1021/ef060311g. [33] Pérez-Hernández R, Mendoza-Anaya D, Mondragón-Galicia G, Espinosa M, Rodrı́guez-Lugo V, Lozada M, et al. Microstructural study of asphaltene precipitated with methylene chloride and n-hexane☆. Fuel 2003;82:977–82. https://doi.org/10.1016/S0016-2361(02)00359-9. [34] Calemma V, Iwanski P, Nali M, Scotti R, Montanari L. Structural characterization of asphaltenes of different origins. Energy Fuels 1995;9:225–30. https://doi.org/ 10.1021/ef00050a004. [35] Molina VD, Ariza E, Poveda JC. Structural differences among the asphaltenes in colombian light crudes from the colorado oil field. Energy Fuels 2017;31:133–9. https://doi.org/10.1021/acs.energyfuels.6b01887. [36] Dutta Majumdar R, Gerken M, Mikula R, Hazendonk P. Validation of the YenMullins Model of athabasca oil-sands asphaltenes using solution-state 1 H NMR relaxation and 2D HSQC spectroscopy. Energy Fuels 2013;27:6528–37. https://doi. org/10.1021/ef401412w. [37] Trejo F, Ancheyta J, Morgan TJ, Herod AA, Kandiyoti R. Characterization of asphaltenes from hydrotreated products by SEC, LDMS, MALDI, NMR, and XRD. Energy Fuels 2007;21:2121–8. https://doi.org/10.1021/ef060621z. Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Appendix A. Supplementary data Supplementary data to this article can be found online at https://doi. org/10.1016/j.fuel.2022.124525. References [1] Carvalho VV, Vasconcelos GA, Tose LV, Santos H, Cardoso FMR, Fleming F, et al. Revealing the chemical characterization of asphaltenes fractions produced by Nmethylpyrrolidone using FTIR, molecular fluorescence, 1H NMR, and ESI(±)FTICR MS. Fuel 2017;210:514–26. https://doi.org/10.1016/j.fuel.2017.08.098. [2] Salehzadeh M, Husein MM, Ghotbi C, Taghikhani V, Dabir B. An integrated approach for predicting asphaltenes precipitation and deposition along wellbores. J Pet Sci Eng 2021;203:108486. https://doi.org/10.1016/j.petrol.2021.108486. [3] Subramanian S, Sørland GH, Simon S, Xu Z, Sjöblom J. Asphaltene fractionation based on adsorption onto calcium carbonate: Part 2. Self-association and aggregation properties. Colloids Surfaces A Physicochem Eng Asp 2017;514:79–90. https://doi.org/10.1016/j.colsurfa.2016.11.035. [4] Christopher J. Chemical structure of bitumen-derived asphaltenes by nuclear magnetic resonance spectroscopy and X-ray diffractometry. Fuel 1996;75: 999–1008. https://doi.org/10.1016/0016-2361(96)00023-3. [5] Ali FA, Ghaloum N, Hauser A. Structure representation of asphaltene GPC fractions derived from Kuwaiti residual oils. Energy Fuels 2006;20:231–8. https://doi.org/ 10.1021/ef050130z. [6] Fossen M, Kallevik H, Knudsen KD, Sjöblom J. Asphaltenes precipitated by a twostep precipitation procedure. 2. Physical and chemical characteristics. Energy Fuels 2011;25:3552–67. https://doi.org/10.1021/ef200373v. [7] Fergoug T, Bouhadda Y. Determination of Hassi Messaoud asphaltene aromatic structure from 1H & 13C NMR analysis. Fuel 2014;115:521–6. https://doi.org/ 10.1016/j.fuel.2013.07.055. [8] Asemani M, Rabbani AR. Detailed FTIR spectroscopy characterization of crude oil extracted asphaltenes: Curve resolve of overlapping bands. J Pet Sci Eng 2020;185: 106618. https://doi.org/10.1016/j.petrol.2019.106618. [9] Sadeghtabaghi Z, Rabbani AR, Hemmati-Sarapardeh A. A review on asphaltenes characterization by X-ray diffraction: Fundamentals, challenges, and tips. J Mol Struct 2021;1238:130425. https://doi.org/10.1016/j.molstruc.2021.130425. [10] Ok S, Mahmoodinia M, Rajasekaran N, Sabti MA, Lervik A, van Erp TS, et al. Molecular structure and solubility determination of asphaltenes. Energy Fuels 2019;33:8259–70. https://doi.org/10.1021/acs.energyfuels.9b01737. [11] Bava YB, Geronés M, Buceta D, de la Iglesia RD, López-Quintela MA, Erben MF. Elucidation of the average molecular structure of argentinian asphaltenes. Energy Fuels 2019;33:2950–60. https://doi.org/10.1021/acs.energyfuels.8b04318. [12] Pereira TMC, Vanini G, Tose LV, Cardoso FMR, Fleming FP, Rosa PTV, et al. FT-ICR MS analysis of asphaltenes: Asphaltenes go in, fullerenes come out. Fuel 2014;131: 49–58. https://doi.org/10.1016/j.fuel.2014.04.049. 11 M. Salehzadeh et al. Fuel 324 (2022) 124525 [38] Andrews AB, Edwards JC, Pomerantz AE, Mullins OC, Nordlund D, Norinaga K. Comparison of coal-derived and petroleum asphaltenes by 13 C nuclear magnetic resonance, DEPT, and XRS. Energy Fuels 2011;25:3068–76. https://doi.org/ 10.1021/ef2003443. [39] Sanchez-Minero F, Ancheyta J, Silva-Oliver G, Flores-Valle S. Predicting SARA composition of crude oil by means of NMR. Fuel 2013;110:318–21. https://doi. org/10.1016/j.fuel.2012.10.027. [40] Rogel E, Roye M, Vien J, Miao T. Characterization of asphaltene fractions: distribution, chemical characteristics, and solubility behavior. Energy Fuels 2015; 29:2143–52. https://doi.org/10.1021/ef5026455. [41] Hurt MR, Borton DJ, Choi HJ, Kenttämaa HI. Comparison of the structures of molecules in coal and petroleum asphaltenes by using mass spectrometry. Energy Fuels 2013;27:3653–8. https://doi.org/10.1021/ef302024z. [42] Hemmati-Sarapardeh A, Dabir B, Ahmadi M, Mohammadi AH, Husein MM. Toward mechanistic understanding of asphaltene aggregation behavior in toluene: The roles of asphaltene structure, aging time, temperature, and ultrasonic radiation. J Mol Liq 2018;264:410–24. https://doi.org/10.1016/j.molliq.2018.04.061. [43] Standard Test Method for Determination of Asphaltenes (Heptane Insolubles) in Crude Petroleum and Petroleum Products 2012. https://doi.org/https://doi.org/ 10.1520/D6560-12. [44] Bagherzadeh H, Golghanddashti H, Shahrabadi A. A proposed systematic approach for experimental asphaltene investigation: an oil-reservoir case study. SPE Prod Oper 2018;33:102–12. https://doi.org/10.2118/187944-PA. [45] Chacón-Patiño ML, Vesga-Martínez SJ, Blanco-Tirado C, Orrego-Ruiz JA, GómezEscudero A, Combariza MY. Exploring occluded compounds and their interactions with asphaltene networks using high-resolution mass spectrometry. Energy Fuels 2016;30:4550–61. https://doi.org/10.1021/acs.energyfuels.6b00278. [46] Stojilovic N. Why can’t we see hydrogen in X-ray photoelectron spectroscopy? J Chem Educ 2012;89:1331–2. https://doi.org/10.1021/ed300057j. [47] Arenas-Alatorre J, Schabes-Retchkiman PS, Rodriguez-Lugo V. Electron microscopy characterization of crystalline nanostructures present in asphaltene. Energy Fuels 2016;30:3752–7. https://doi.org/10.1021/acs.energyfuels.5b02407. [48] Polini A, Yang F. Physicochemical characterization of nanofiber composites. Nanofiber Compos Biomed Appl, Elsevier 2017:97–115. https://doi.org/10.1016/ B978-0-08-100173-8.00005-3. [49] Horgnies M, Darque-Ceretti E, Fezai H, Felder E. Influence of the interfacial composition on the adhesion between aggregates and bitumen: Investigations by EDX, XPS and peel tests. Int J Adhes Adhes 2011;31:238–47. https://doi.org/ 10.1016/j.ijadhadh.2011.01.005. [50] Acevedo, Sócrates, Luis B. Gutierrez, Gabriel Negrin, Juan Carlos Pereira, Bernardo Mendez, Frederic Delolme, Guy Dessalces and DB. Molecular weight of petroleum asphaltenes: A comparison between mass spectrometry and vapor pressure osmometry. Energy & Fuels 2005;19:1548–60. https://doi.org/https://doi.org/ 10.1021/ef040071+. [51] Groenzin H, Mullins OC. Asphaltene molecular size and structure. J Phys Chem A 1999;103:11237–45. https://doi.org/10.1021/jp992609w. [52] Morgan TJ, Alvarez-Rodriguez P, George A, Herod AA, Kandiyoti R. Characterization of maya crude oil maltenes and asphaltenes in terms of structural parameters calculated from nuclear magnetic resonance (NMR) spectroscopy and laser desorption− mass spectroscopy (LD− MS). Energy Fuels 2010;24:3977–89. https://doi.org/10.1021/ef100320t. [53] AlHumaidan FS, Hauser A, Rana MS, Lababidi HMS. Impact of thermal treatment on asphaltene functional groups. Energy Fuels 2016;30:2892–903. https://doi.org/ 10.1021/acs.energyfuels.6b00261. [54] Guillén MD, Iglesias MJ, Domínguez A, Blanco CG. Fourier transform infrared study of coal tar pitches. Fuel 1995;74:1595–8. https://doi.org/10.1016/00162361(95)00139-V. [55] Coelho RR, Hovell I, de Mello Monte MB, Middea A, Lopes de Souza A. Characterisation of aliphatic chains in vacuum residues (VRs) of asphaltenes and resins using molecular modelling and FTIR techniques. Fuel Process Technol 2006; 87:325–33. https://doi.org/10.1016/j.fuproc.2005.10.010. [56] Yang F, Tchoukov P, Dettman H, Teklebrhan RB, Liu L, Dabros T, et al. Asphaltene subfractions responsible for stabilizing water-in-crude oil emulsions. Part 2: Molecular Representations and molecular dynamics simulations. Energy Fuels 2015;29:4783–94. https://doi.org/10.1021/acs.energyfuels.5b00657. [57] Brondel N, Moynihan EJA, Lehane KN, Eccles KS, Elcoate CJ, Coles SJ, et al. Does intermolecular S O⋯H–C–S O hydrogen bonding in sulfoxides and sulfones provide a robust supramolecular synthon in the solid state? CrystEngComm 2010;12:2910. https://doi.org/10.1039/c000371a. [58] AlHumaidan FS, Hauser A, Rana MS, Lababidi HMS. NMR characterization of asphaltene derived from residual oils and their thermal decomposition. Energy Fuels 2017;31:3812–20. https://doi.org/10.1021/acs.energyfuels.6b03433. [59] Salehzadeh M, Kaminski T, Husein MM. An optimized thermal cracking approach for onsite upgrading of bitumen. Fuel 2022;307:121885. https://doi.org/10.1016/ j.fuel.2021.121885. [60] Abdul Jameel AG, Elbaz AM, Emwas A-H, Roberts WL, Sarathy SM. Calculation of average molecular parameters, functional groups, and a surrogate molecule for heavy fuel oils using 1 H and 13 C nuclear magnetic resonance spectroscopy. [61] [62] [63] [64] [65] [66] [67] [68] [69] [70] [71] [72] [73] [74] [75] [76] [77] [78] [79] [80] [81] 12 Energy Fuels 2016;30:3894–905. https://doi.org/10.1021/acs. energyfuels.6b00303. Gillet S, Rubini P, Delpuech J-J, Escalier J-C, Valentin P. Quantitative carbon-13 and proton nuclear magnetic resonance spectroscopy of crude oil and petroleum products. I. Some rules for obtaining a set of reliable structural parameters. Fuel 1981;60:221–5. https://doi.org/10.1016/0016-2361(81)90183-6. Gillet S, Rubini P, Delpuech J-J, Escalier J-C, Valentin P. Quantitative carbon-13 and proton nuclear magnetic resonance spectroscopy of crude oil and petroleum products. 2. Average structure parameters of representative samples. Fuel 1981;60: 226–30. https://doi.org/10.1016/0016-2361(81)90184-8. Hasan M, Ali M, Bukhari A. Structural characterization of Saudi Arabian heavy crude oil by n.m.r. spectroscopy. Fuel 1983;62:518–23. https://doi.org/10.1016/ 0016-2361(83)90219-3. Ruiz-Morales Y, Miranda-Olvera AD, Portales-Martı́nez B, Domı́nguez JM. Experimental and theoretical approach to determine the average asphaltene structure of a crude oil from the golden lane (Faja de Oro) of Mexico. Energy Fuels 2020;34:7985–8006. https://doi.org/10.1021/acs.energyfuels.0c00593. Ruiz-Morales Y, Miranda-Olvera AD, Portales-Martínez B, Domínguez JM. Determination of 13 C NMR chemical shift structural ranges for polycyclic aromatic hydrocarbons (PAHs) and PAHs in Asphaltenes: An experimental and theoretical density functional theory study. Energy Fuels 2019;33:7950–70. https://doi.org/10.1021/acs.energyfuels.9b00182. Sheng Q, Wang G, Jin N, Husein MM, Gao J. Three-level structure change of asphaltenes undergoing conversion in a hydrogen donor solvent. Fuel 2019;255: 115736. https://doi.org/10.1016/j.fuel.2019.115736. Hosseinpour N, Khodadadi AA, Bahramian A, Mortazavi Y. Asphaltene adsorption onto acidic/basic metal oxide nanoparticles toward in situ upgrading of reservoir oils by nanotechnology. Langmuir 2013;29:14135–46. https://doi.org/10.1021/ la402979h. Bouhadda Y, Bendedouch D, Sheu E, Krallafa A. Some preliminary results on a physico-chemical characterization of a hassi messaoud petroleum asphaltene. Energy Fuels 2000;14:845–53. https://doi.org/10.1021/ef9902092. Yakubov MR, Abilova GR, Sinyashin KO, Milordov DV, Tazeeva EG, Yakubova SG, et al. Inhibition of asphaltene precipitation by resins with various contents of vanadyl porphyrins. Energy Fuels 2016;30:8997–9002. https://doi.org/10.1021/ acs.energyfuels.6b01503. Spiecker PM, Gawrys KL, Trail CB, Kilpatrick PK. Effects of petroleum resins on asphaltene aggregation and water-in-oil emulsion formation. Colloids Surfaces A Physicochem Eng Asp 2003;220:9–27. https://doi.org/10.1016/S0927-7757(03) 00079-7. Liu L, Zhang R, Wang X, Simon S, Sjöblom J, Xu Z, et al. Interactions of Polyaromatic Compounds. Part 1: Nanoaggregation Probed by Electrospray Ionization Mass Spectrometry and Molecular Dynamics Simulation. Energy Fuels 2017;31:3465–74. https://doi.org/10.1021/acs.energyfuels.6b03029. Wattana P, Fogler HS, Yen A, Del Carmen Garcìa M, Carbognani L. Characterization of Polarity-Based Asphaltene Subfractions. Energy Fuels 2005;19: 101–10. https://doi.org/10.1021/ef0499372. Wang X, Zhang R, Liu L, Qiao P, Simon S, Sjöblom J, et al. Interactions of polyaromatic compounds. part 2. flocculation probed by dynamic light scattering and molecular dynamics simulation. Energy Fuels 2017;31:9201–12. https://doi. org/10.1021/acs.energyfuels.7b01511. Pradilla D, Subramanian S, Simon S, Sjöblom J, Beurroies I, Denoyel R. Microcalorimetry study of the adsorption of asphaltenes and asphaltene model compounds at the liquid-solid surface. Langmuir 2016;32:7294–305. https://doi. org/10.1021/acs.langmuir.6b00816. Sedghi M, Goual L, Welch W, Kubelka J. Effect of asphaltene structure on association and aggregation using molecular dynamics. J Phys Chem B 2013;117: 5765–76. https://doi.org/10.1021/jp401584u. Klein GC, Kim S, Rodgers RP, Marshall AG, Yen A. Mass spectral analysis of asphaltenes. II. Detailed compositional comparison of asphaltenes deposit to its crude oil counterpart for two geographically different crude oils by ESI FT-ICR MS. Energy Fuels 2006;20:1973–9. https://doi.org/10.1021/ef0600208. Sedghi M, Goual L. Role of resins on asphaltene stability. Energy Fuels 2010;24: 2275–80. https://doi.org/10.1021/ef9009235. Santos Silva H, Alfarra A, Vallverdu G, Bégué D, Bouyssiere B, Baraille I. Asphaltene aggregation studied by molecular dynamics simulations: role of the molecular architecture and solvents on the supramolecular or colloidal behavior. Pet Sci 2019;16:669–84. https://doi.org/10.1007/s12182-019-0321-y. Yaseen S, Mansoori GA. Molecular dynamics studies of interaction between asphaltenes and solvents. J Pet Sci Eng 2017;156:118–24. https://doi.org/ 10.1016/j.petrol.2017.05.018. Aray Y, Hernández-Bravo R, Parra JG, Rodríguez J, Coll DS. Exploring the structure-solubility relationship of asphaltene models in toluene, heptane, and amphiphiles using a molecular dynamic atomistic methodology. J Phys Chem A 2011;115:11495–507. https://doi.org/10.1021/jp204319n. Tirjoo A, Bayati B, Rezaei H, Rahmati M. Molecular dynamics simulations of asphaltene aggregation under different conditions. J Pet Sci Eng 2019;177: 392–402. https://doi.org/10.1016/j.petrol.2019.02.041.