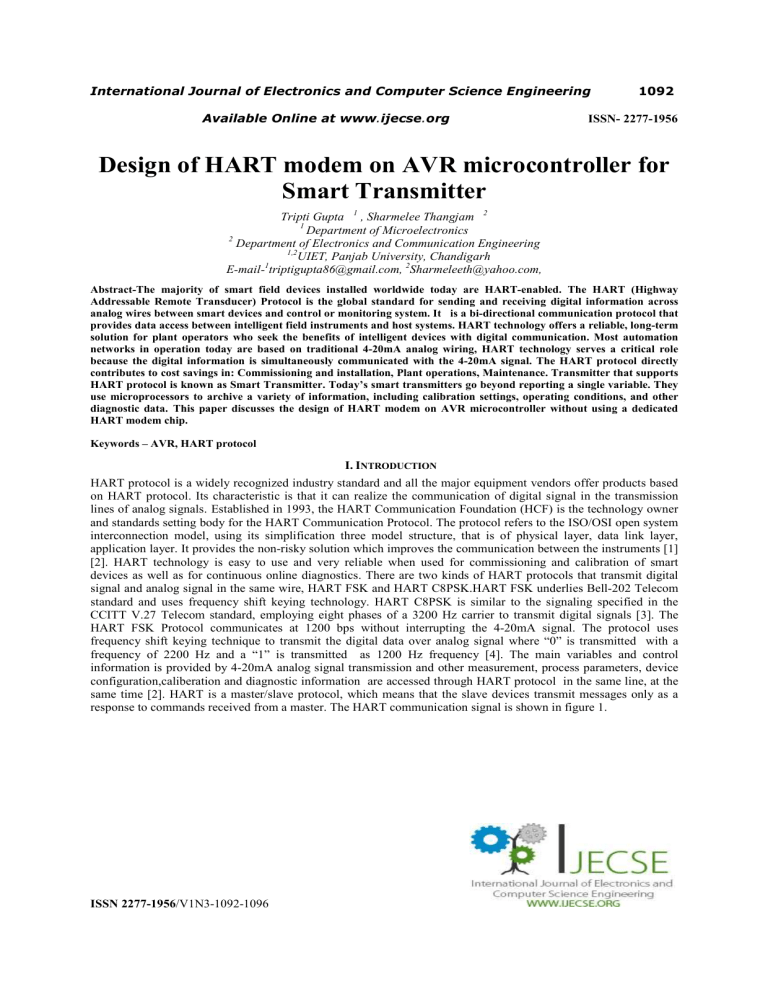

International Journal of Electronics and Computer Science Engineering Available Online at www.ijecse.org 1092 ISSN- 2277-1956 Design of HART modem on AVR microcontroller for Smart Transmitter Tripti Gupta 1 , Sharmelee Thangjam 2 1 Department of Microelectronics 2 Department of Electronics and Communication Engineering 1,2 UIET, Panjab University, Chandigarh E-mail-1triptigupta86@gmail.com, 2Sharmeleeth@yahoo.com, Abstract-The majority of smart field devices installed worldwide today are HART-enabled. The HART (Highway Addressable Remote Transducer) Protocol is the global standard for sending and receiving digital information across analog wires between smart devices and control or monitoring system. It is a bi-directional communication protocol that provides data access between intelligent field instruments and host systems. HART technology offers a reliable, long-term solution for plant operators who seek the benefits of intelligent devices with digital communication. Most automation networks in operation today are based on traditional 4-20mA analog wiring, HART technology serves a critical role because the digital information is simultaneously communicated with the 4-20mA signal. The HART protocol directly contributes to cost savings in: Commissioning and installation, Plant operations, Maintenance. Transmitter that supports HART protocol is known as Smart Transmitter. Today’s smart transmitters go beyond reporting a single variable. They use microprocessors to archive a variety of information, including calibration settings, operating conditions, and other diagnostic data. This paper discusses the design of HART modem on AVR microcontroller without using a dedicated HART modem chip. Keywords – AVR, HART protocol I. INTRODUCTION HART protocol is a widely recognized industry standard and all the major equipment vendors offer products based on HART protocol. Its characteristic is that it can realize the communication of digital signal in the transmission lines of analog signals. Established in 1993, the HART Communication Foundation (HCF) is the technology owner and standards setting body for the HART Communication Protocol. The protocol refers to the ISO/OSI open system interconnection model, using its simplification three model structure, that is of physical layer, data link layer, application layer. It provides the non-risky solution which improves the communication between the instruments [1] [2]. HART technology is easy to use and very reliable when used for commissioning and calibration of smart devices as well as for continuous online diagnostics. There are two kinds of HART protocols that transmit digital signal and analog signal in the same wire, HART FSK and HART C8PSK.HART FSK underlies Bell-202 Telecom standard and uses frequency shift keying technology. HART C8PSK is similar to the signaling specified in the CCITT V.27 Telecom standard, employing eight phases of a 3200 Hz carrier to transmit digital signals [3]. The HART FSK Protocol communicates at 1200 bps without interrupting the 4-20mA signal. The protocol uses frequency shift keying technique to transmit the digital data over analog signal where “0” is transmitted with a frequency of 2200 Hz and a “1” is transmitted as 1200 Hz frequency [4]. The main variables and control information is provided by 4-20mA analog signal transmission and other measurement, process parameters, device configuration,caliberation and diagnostic information are accessed through HART protocol in the same line, at the same time [2]. HART is a master/slave protocol, which means that the slave devices transmit messages only as a response to commands received from a master. The HART communication signal is shown in figure 1. ISSN 2277-1956/V1N3-1092-1096 1093 Design of HART modem on AVR microcontroller for Smart Transmitter Figure1. Simultaneous analog and digital communication II. HART MODEM HART modem chip is used to implement a complete HART signal modulation and demodulation. HART standard defines 1200 Hz and 2200 Hz as two frequencies which represent logic 1 and 0 respectively. For communication purpose these frequencies need to be converted from frequency signal to digital logic signal and vice versa. HART modem functionality is implemented on software and replaces hardware modem chip with minimal hardware, comprising of filters and comparators only. A. HART modulatorHART Modulator uses PWM generation feature of microcontroller timer and generates PWM corresponding to 1200Hz and 2200Hz sine waves of HART signal. These signals are filtered by passive hardware filters and converted to sine waves. Figure 2 shows the blocks of HART modulator. UART data@1200bps HART signal frequency selector logic PWM duty cycle selector 2nd order passive LPF HART FSK output Figure2. HART Modulator B. HART demodulator – HART demodulator shown in figure 3 is based on conversion of digital signal from a zero crossing detector circuit. Zero crossing Detector converts sine waves of HART signal to digital pulses, these pulses are delayed and XORed with its parent signal.LPF recovers the DC average output of the XOR circuit. Again a zero crossing detector is used and the digital output is stable and noise free. ISSN 2277-1956/V1N3-1092-1096 IJECSE,Volume1,Number 3 Tripti Gupta and Sharmelee Thangjam HART FSK input Butterworth 2nd order HPF & 1st order LPF to accommodate HART signal band only Zero crossing Detector UART data @1200bps Delay algorithm Zero crossing Detector XOR with parent signal Hardware based low pass filtering Figure3. HART Demodulator III. IMPLEMENTATION ON AVR MICROCONTROLLER HART modem can be implemented on AVR microcontroller as shown in figure 4. For demodulator, hardware filters consists of 2nd order active HPF and a 1st order passive LPF. HPF is designed for a cutoff frequency of 1000Hz (approx.) and LPF for a cutoff frequency of 2400Hz (approx). Filtered signal is passed through a zero crossing detector (ZCD) section which converts sine wave signal to digital pulses. Filters and ZCD can be implemented in different ways as listed below: Using active 2nd order HPF and passive 1st order LPF and ZCD can be implemented using analog comparator peripheral of microcontroller. Using Op-amp for 2nd order HPF, a passive 1st order LPF and ZCD can be implemented using comparator stage. Output of ZCD is fed to microcontroller GPIO pin, capable of issuing interrupts on rising and falling edges of signal. The functions delayed and XORed with parent signal are performed by microcontroller. For modulator, microcontroller software needs to generate PWM corresponding to sine frequencies of HART signal. Modulator is implemented inside AVR microcontroller, baud rate of 1200bps and its frame format can be generated using timer interrupt and software will know (programmed timer interrupts) when to transmit frequencies corresponding to 1 or 0.HART sine wave signal is to be generated by varying PWM duty cycle. Table of those duty cycles is stored in program memory. Based on which frequency is to be generated, software selects duty cycle samples and loads to PWM duty cycle registers. External to microcontroller a 2nd order passive LPF is used to remove out high frequency switching noise and give 1200Hz and 2200Hz sine waves. This approach is easy to implement, uses less hardware and software resources. ISSN 2277-1956/V1N3-1092-1096 1095 Design of HART modem on AVR microcontroller for Smart Transmitter HART FSK input Butterworth 2nd order HPF & 1st order LPF to accommodate HART signal band only Zero crossing Detector Low pass filter GPIO AVR MICROCONTROLLER Zero crossing Detector HART FSK output 2nd order passive LPF UART RX GPIO Figure4. Implementation on AVR microcontroller IV. AVR MICROCONTROLLER AVR (Advanced Virtual RISC) has RISC (Reduced Instruction set computer) Harvard architecture. It is a general purpose and cheap microcontroller. Instructions are executed in single clock cycle so it is a fast microcontroller. It has high performance, consumes less power and can be operated in different power saving mode. AVR has in built A/D converter and on chip analog comparator which is not present in any other microcontroller. It has a real time counter, Programmable Serial USART, Master/Slave SPI Serial Interface, Programmable Watchdog Timer with Separate On-Chip Oscillator, Two 8-bit Timer/Counters with Separate Prescaler and Compare Modes. These features of AVR microcontroller are used to perform the modulation and demodulation in HART modem. V. SMART TRANSMITTER Smart transmitters use the same two-wire connection and analog signaling (4 mA to 20 mA). However, in this kind of transmitters, the signal from the sensor is digitized, and then digital processing is performed by a microcontroller. This approach has two important advantages: 1) it enables good compensation of sensor nonlinearity; 2) it enables the use of additional sensors in order to compensate the influence of parasitic parameters. Smart transmitters belong to the third technology generation. VI. APPLICATION AREAS HART modem is used in industries to transmit large number of signals from field point to control panel to collect data like temperature, humidity, pressure, flow rate of a gas, level measurement for further study, Open architecture ISSN 2277-1956/V1N3-1092-1096 IJECSE,Volume1,Number 3 Tripti Gupta and Sharmelee Thangjam applications-oil refinery applications, Remote- operation applications, Cost saving applications-water treatment facility upgrade, Inventory-management applications-underground petroleum storage with HART communication for accuracy, waste water treatment plant upgrade[5]. The HART modem can also be installed as an external peripheral. It could be useful because many instrumentation software used to setup and to calibrate a measurement sensor or to establish a diagnostic, often need a serial port to dialog with the transducer. HART modem is a smart tool for an automation engineer to configure a sensor or another device, or to maintain it by linking either locally (directly) or remotely. VII. CONCLUSION In today's competitive environment, everyone wants to find ways that can help in reducing operational costs, deliver products rapidly, and improve quality. The HART Protocol directly contributes to these business goals by providing cost savings in: Commissioning and installation, Improve plant operations, Provides improved plant quality, Reduce maintenance costs. Most smart devices are configured using the HART Protocol. The HART Protocol provides two simultaneous communication channels – the 4-20mA analog channel and the HART-digital channel that is superimposed on the analog channel. HART modulator modulates the data received from the communication port and adds this signal to the analog signal to build the 4-20 mA composite signal. The HART demodulator extracts the modulated signal from the 4-20 mA composite signals and demodulates it into digital signal. Earlier HART modem functionality has been implemented using off-the-shelf HART Modems such as A5191HRT modem by AMIS or the HT2015 by Smart Research etc. This comes at the cost of the modem chip and additional board space required to mount it. By using various features of AVR microcontroller, HART is implemented on AVR which performs modulation and demodulation functions. This uses minimal hardware and minimal CPU resources thus the total cost and space can be reduced. Design elements like filters and algorithms are used which improve the quality of HART modem. VIII. REFERENCES [1] Zeng Mingru, You Wentang, Qian Xin. “The Development of Intelligent Pressure Transmitter based on HART Protocol” Intelligent Conference on E-Health Networking, Digital Ecosystems and Technologies, 2010. [2] A Guochen, Meng Zhiyong, Ma Hongtao, Sui Bingdong. “Design of Intelligent Transmitter based on HART Protocol” International Conference on Intelligent Computation Technology and Automation, 2010. [3] Jin Zhenghua, Wang Hong, Yang Zhijia. “Joint Design of signal Detection, Demodulation Classification, Channel Estimation and Automatic Gain Control for Multi Speed HART” International Conference on Computer Design and Applications, 2010 [4] J.M.Dias Pereira, O.Postolache, P.Silva Girao. “HART protocol Analyser based in LabVIEW” IEEE International Workshop on Intelligent Data Acquisition and advanced computing systems: Technology and Applications, 2003. [5] Jim Mitchem. “Automated calibration aids smooth turnover of new plants” IEEE Instrumentation & Measurement Magazine, 2004. ISSN 2277-1956/V1N3-1092-1096